Because the pitch (or lead) of the thread is specified by the drawing, the key to choose the cutting parameters when turning the screw thread is to determine the spindle speed n and the cutting depth AP.

1) SELECTION OF SPINDLE SPEED TO DO SCREW THREAD TURNING

According to the mechanism that the spindle turns 1 and the cutter feeds 1 lead when turning the thread, the feed speed of the CNC lathe is determined by the selected spindle speed. The thread lead (which is the pitch when the thread is single head thread) instructed in the thread processing program section is equivalent to the feed speed VF VF = n f (1) expressed by the feed rate f (mm / R)

From Formula 1, it can be seen that the feed speed VF is proportional to the feed amount F. if the spindle speed of the machine tool is selected too high, the converted feed speed will greatly exceed the rated feed speed of the machine tool. Therefore, when selecting the rotation speed of the main shaft for turning the thread, the parameter setting of the feeding system and the electrical configuration of the machine tool should be considered to avoid the phenomenon of “disordered thread” or the thread pitch near the start / end point not meeting the requirements.

In addition, it is worth noting that once the thread processing is started, the spindle speed value cannot be changed generally, and the spindle speed including finishing must follow the selected value during the first feed machining. Otherwise, the CNCsystem will lead to “disordered thread” due to the “overshoot” of the reference pulse signal of the pulse encoder.

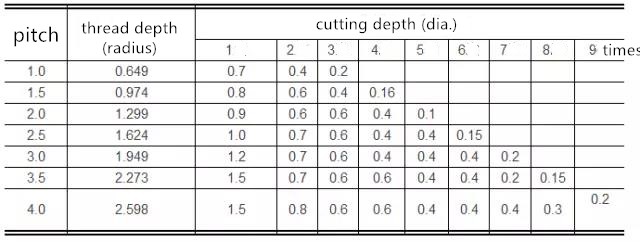

2) SELECTION OF CUTTING DEPTH TO DO SCREW THREAD TURNING

Because the thread turning is a forming turning, the strength of the cutting tool is poor, and the cutting feed is large, and the cutting force on the cutting tool is also large. Therefore, it is generally required to select a relatively reasonable cutting depth according to the decreasing trend. Table 1 lists the feed times and cutting depth reference values of common metric thread cutting for readers to consult.

Table 1 feed times and cutting depth of common metric thread cutting

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making,Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论