Do you know how to deal with these problems in CNC machining?

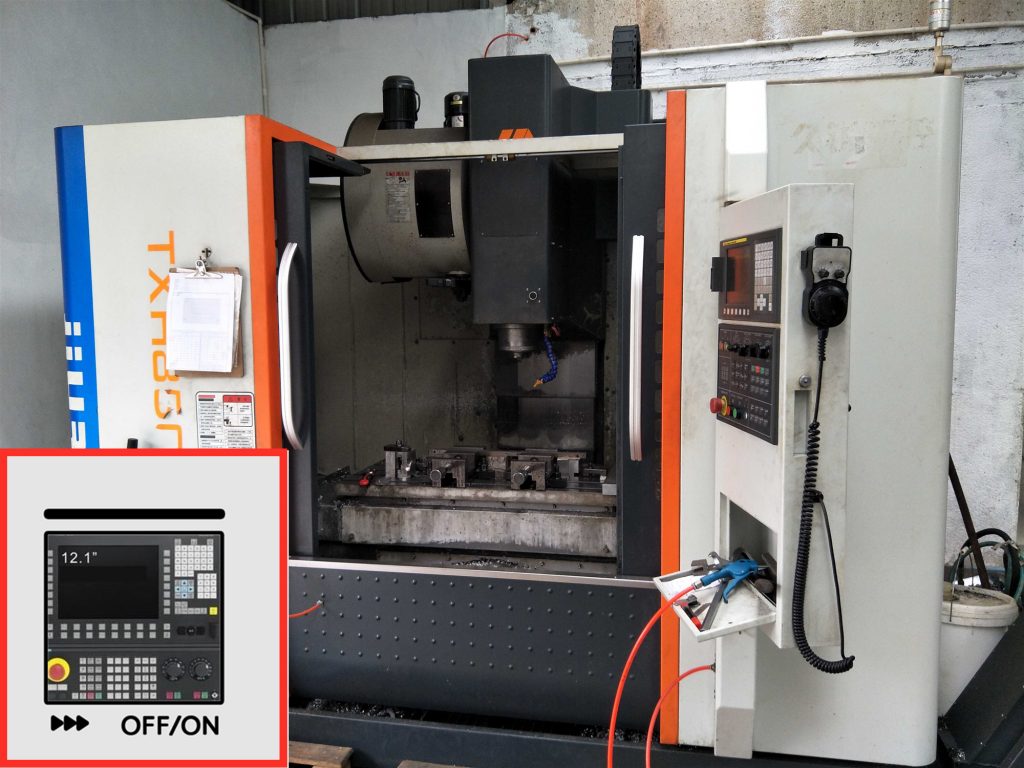

CNC NC Programming Routine explain your question! More information about CNC machine or router control panel buttons & keys, please read: “what are the mean of CNC machine buttonS & keys?“

CNC NC Programming Routine, Normal Machining problems & Solution

OVERCUTTING OF MACHINING WORKPIECE:

OVER CUTTING REASON:

- Ballistic cutter, tool strength is not too long or too small, resulting in tool bouncing cutting tool.

- The operator operates improperly.

- Cutting allowance is not uniform. (e.g. 0.5 on the side and 0.15 on the bottom of the curved surface)

- Improper cutting parameters (such as too big tolerance, too fast SF setting, etc.).

IMPROVE METHODS:

- The principle of using knives/cutters: big or small, short or short.

- Add angle clearing procedures, and keep the margin as evenly as possible. (The side and bottom margins remain the same.)

- Reasonably adjust the cutting parameters and round the corner with large margin.

- Using SF function of machine tool, the operator can adjust the speed slightly to achieve the best effect of machine tool cutting.

CENTERING PROBLEMS ( TO FIND THE POSITION OF THE MACHINING WORKPIECE IN THE COORDINATE SYSTEM OF THE CNC MACHINE CENTER.

REASON ANALYSIS OF CENTERING PROBLEMS IN NC MACHINING PROCESS:

- Operator’s manual operation is inaccurate.

- There are burrs around the die.

- There is magnetism in the middle bar.

- The four sides of the die are not vertical.

IMPROVE CENTERING OPERATION:

- Manual operation should be carefully checked repeatedly, and the points should be as high as possible at the same point.

- Use oil stone or file to deburr the periphery of the die and wipe it clean with rags, and finally confirm it by hand.

- Demagnetize the middle bar before dividing the die. (Ceramic can be used to divide the middle bar or other parts.)

- Calibration check whether the four sides of the die are vertical. (Verticality error needs to be checked with fitter scheme.)

CUT TOOL SETTING PROBLEM:

REASON ANALYSIS OF CUTTING TOOL SETTING :

- Operator’s manual operation is inaccurate.

- Error in tool clamping.

- The blade on the flying knife is wrong (the flying knife itself has some errors).

- There are errors between R knife and flat bottom knife and flying knife.

IMPROVE METHODS OF CUTTER SETTING:

- Manual operation should be checked repeatedly and carefully, and the knife should be checked at the same point as possible.

- Clean the tool with air gun or rag when clamping.

- A blade can be used when measuring the tool rod and smooth bottom of the blade on the flying knife.

- The error between the flat and flying knives of R-knife can be avoided by setting up a tool-setting program separately.

MACHINE COLLISION – PROGRAMMING:

REASON OF MACHINE COLLISION:

- Insufficient or no safety height (knife or chuck hitting workpiece when fast feed G00).

- Writing errors of tool on program sheet and actual program tool.

- Writing errors in tool length (edge length) and actual depth of machining on program sheet.

- Writing errors of Z-axis number of depth and actual Z-axis number on program sheet.

- Error of coordinate setting in programming.

IMPROVE METHOD:

- Accurate measurement of workpiece height also ensures that the safety height is above the workpiece.

- The tool on the program sheet should be consistent with the actual program tool (try to use the automatic program sheet or the picture to produce the program sheet).

- Measure the actual depth of the workpiece. Write clearly the length of the tool and the length of the edge on the program sheet (the general tool clamp length is 2-3MM higher than the workpiece, and the length of the blade avoids void is 0.5-1.0MM).

- Take the actual Z-axis number on the workpiece and write it clearly on the program sheet. (This operation is usually written for manual operation to be checked repeatedly).

CUT TOOL COLLISION – OPERATOR:

REASON:

- Deep Z-axis tool alignment error.

- Errors in the number of collisions and operations (e.g. the number taken unilaterally has no radius of feed, etc.).

- Use wrong knife (e.g. D4 knife and D10 knife).

- Program error (e.g. A7.NC goes A9.NC).

- The handwheel is rocking in the wrong direction during manual operation.

- Manual fast feed in wrong direction (e.g. – X press + X).

IMPROVE:

- Deep Z-axis tool alignment must pay attention to the position of tool alignment. (Bottom, top, analysis, etc.).

- The number of collisions and operands in points should be checked repeatedly after they are completed.

- When clamping the tool, it should be checked repeatedly against the program sheet and program before loading.

- Procedures should go one by one in order.

- When using manual operation, the operator himself should strengthen the operation proficiency of the machine tool.

- When moving rapidly by hand, Z-axis can be raised to the workpiece and moved.

SURFACE ACCURACY:

REASON:

- The cutting parameters are unreasonable and the workpiece surface is rough.

- The cutting edge is not sharp.

- Tool clamping is too long and blade avoidance is too long.

- Scrap removal, air blowing, oil flushing is not good.

- Programming cutter-walking mode, (you can consider milling as far as possible).

- Workpiece has burrs.

IMPROVE:

- Cutting parameters, tolerances, allowances and speed feed should be set reasonably.

- Tools require operators to inspect and replace them irregularly.

- When clamping the tool, the operator is required to clamp it as short as possible and the blade avoidance is not too long.

- For flat knife, R knife and round nose knife, the setting of speed feed should be reasonable.

- Workpieces have burrs: the root of our machine tools, cutting tools, the way we move the knife has a direct relationship. So we need to understand the performance of machine tools and repair burred edges.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making,Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论