Aluminum is the most widely used non-ferrous metal material. And its application range is still expanding. The use ofaluminum product is a wide variety & numerous, more than 700,000 species, from the construction decoration industry to transportation and aerospace and other industries have different needs.

Today, we will to introduce the processing methods of aluminum product.

The advantages and characteristics of aluminum are as follows:

- Low density. The density of aluminum is about 2.7g/cm3. Its density is only 1/3 of iron or copper.

- High plasticity. Aluminum is malleable and can be made into a variety of supplies by squeezing, stretching and other pressure processing means.

- Corrosion resistance. Aluminum is a highly charged metal that produces a protective oxide film on the surface of natural conditions or anodization, with much better corrosion resistance than steel.

- Easy to strengthen. The strength of pure aluminum is not high, but it can be increased by anode oxidation.

- Easy surface treatment. Surface treatment can further improve or change the surface performance of aluminum. Aluminum anode oxidation process is quite mature, stable operation, in the process of aluminum products has been widely used.

- Conductelectricity is good, easy to recycle.

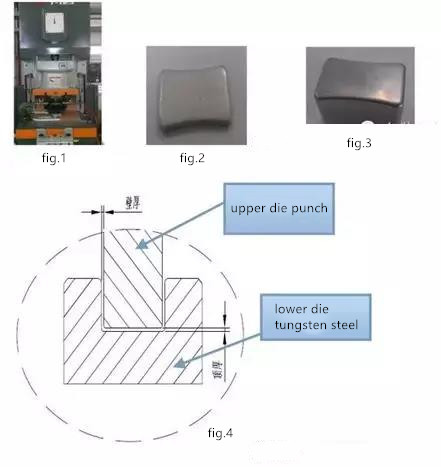

PUNCHING OF ALUMINIUM PRODUCT

COLD STAMPING ALUMINIUM PRODUCT

Use aluminium particles. The extruder table and die are used for one-time forming, which is suitable for cylindrical products or product shapes that are difficult to achieve in drawing process, such as ellipse, square and rectangular products. (Fig. 1 machine, Fig. 2 aluminium particles, Fig. 3 products)

The tonnage of the machine is related to the cross section area of the product. The gap between the upper die punch and the lower die tungsten steel is the wall thickness of the product. The vertical gap between the upper die punch and the lower die tungsten steel is the top thickness of the product when the pressing is completed. (Fig. 4)

ALUMINUM COLD STAMPING ADVANTAGES:

Shorter mold making cycle and lower development cost compared with drawing die.

ALUMINUM COLD STAMPING DISADVANTAGE:

The production process is long, the product size fluctuates greatly in the process, and the labor cost is high.

TENSILE/DRAWING PROCESS FOR ALUMINIUM PRODUCT

Use aluminium sheet. The continuous punching machine and die are used to deform many times to meet the requirement of shape, which is suitable for non-cylindrical products (aluminium products with bending). (Fig. 5, Fig. 6, Mould, Fig. 7, Fig. 7)

ALUMINUM TENSILE OR DRAWING PROCESS ADVANTAGES:

Complicated and multi-deformation products have stable size control and smooth surface in the production process.

ALUMINUM TENSILE OR DRAWING PROCESS DISADVANTAGE:

Die cost is high, development cycle is relatively long, and the selection and precision of machine platform is high.

CNC MACHINING ALUMINUM PRODUCT

Aluminum CNC turning and CNC milling is widely used to making aluminum products.

Aluminum CNC turned part, by CNC LATHE can mass making turned parts with low cost, and machined parts have bright and smooth surface.

Aluminum CNC milled part, by CNC machine center or CNC router to making rapid prototype, fixuture, mold and other aluminum products. The cost is expensive, but can got finised parts quickly from design to product.

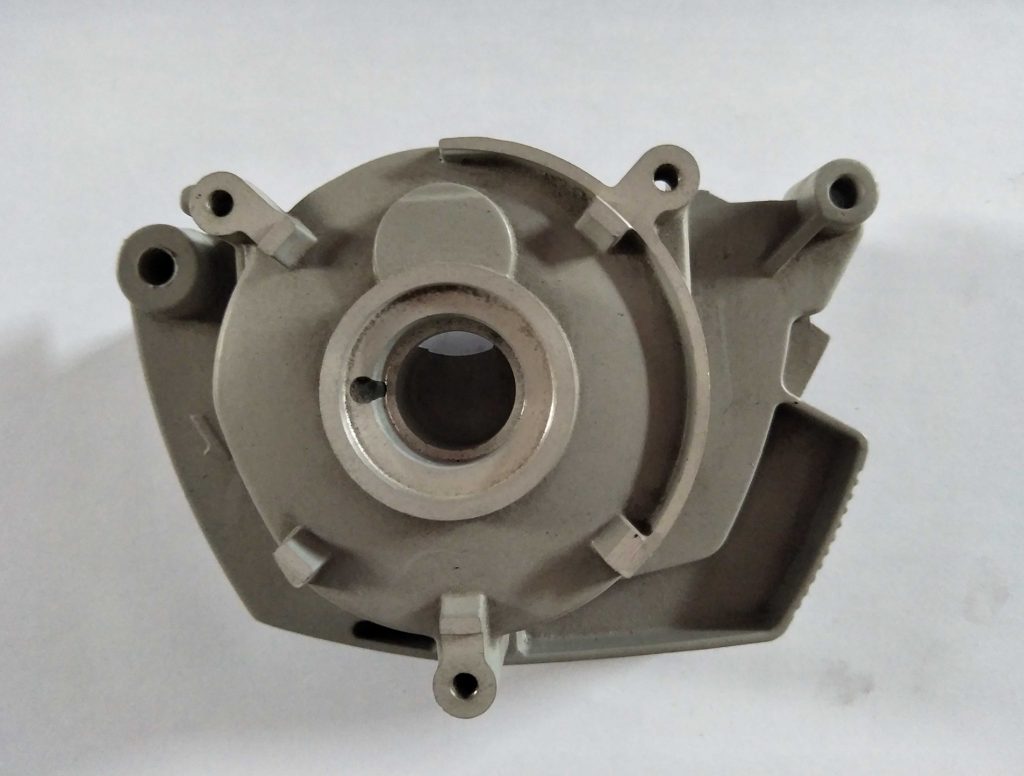

ALUMINUM DIE CASTING

Aluminum die casting product is producing engineered metal parts by forcing molten Aluminum metal under high pressure into reusable steel molds.

Die castings are among the highest volume, mass-produced items manufactured by the metalworking industry, and they can be found in thousands of consumer, commercial, and industrial products. Die cast parts are important components of products ranging from automobiles to toys. Parts can be as simple as a sink faucet or as complex as a connector housing.

Die castings are among the highest volume, mass-produced items manufactured by the metalworking industry, and they can be found in thousands of consumer, commercial, and industrial products. Die cast parts are important components of products ranging from automobiles to toys. Parts can be as simple as a sink faucet or as complex as a connector housing.

ALUMINIUM PRODUCT SURFACE TREATMENT

SANDBLASTING (SHOT BLASTING)

The process of cleaning and roughening metal surface by the impact of high-speed sand flow.

The surface treatment of aluminium parts by this method can obtain a certain degree of cleanliness and different roughness, and improve the mechanical properties of the workpiece surface. Therefore, the fatigue resistance of the workpiece is improved, the adhesion between the workpiece and the coating is increased, the durability of the coating is prolonged, and it is also conducive to the leveling and decoration of the coating. 。 This process is often seen in various products of Apple.

POLISHING

The surface roughness of workpiece is reduced by mechanical, chemical or electrochemical action to obtain a bright and smooth surface processing method. Polishing technology is mainly divided into: mechanical polishing, chemical polishing, electrolytic polishing. Aluminum parts can approach mirror effect of stainless steel after mechanical polishing and electrolytic polishing. This process gives people a feeling of high-grade, simple and fashionable future.

WIRE DRAWING

Metal wire drawing is a process of repeatedly scraping aluminium sheet out of line with sandpaper. Drawing can be divided into straight wire drawing, screwed wire drawing, screwed wire drawing, screwed wire drawing. Metal wire drawing process can clearly show each fine trace, so that the metal matte gloss in the exudation of fine silk luster, products both fashionable and technological sense.

HIGH-LIGHT CUTTING/MACHINING

The diamond knife is strengthened on the spindle of the high-speed CNC router to cut the parts, and a local bright area is generated on the surface of the product. It also named: CNC machining. The brightness of cutting highlight is affected by the speed of the milling bit. The faster the bit speed is, the brighter the cutting highlight is. On the contrary, the darker the cutting highlight is and the easier the cutter grain is. In recent years, high-light CNC milling technology has been used in some metal frames of high-end TV sets. In addition, the anodic oxidation and wire drawing technology make TV sets full of fashion sense and sharp sense of science and technology.

ANODIC OXIDATION

Anodic oxidation refers to the electrochemical oxidation of metals or alloys. Under the corresponding electrolyte and specific technological conditions, aluminum and its alloys form an oxide film on the aluminium products (anodes) due to the action of applied current. Anodic oxidation can not only solve the defects of surface hardness and wear resistance of aluminium, but also prolong the service life of aluminium and enhance its beauty. It has become an indispensable part of surface treatment of aluminium. It is the most widely used and very successful technology at present.

TWO-COLOR ANODE

Dual-color anode refers to the process of anodizing a product and giving different colors to a specific area. Dual-color anodizing process is seldom used in TV industry because of its complex process and high cost, but through the contrast between the two colors, it can better reflect the high-end and unique appearance of the product.

More information about Machined parts surface treatment, please kindly visit: KYLT MACHINED PARTS

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论