CNC milling process adopt Down milling or Up milling? Which milling method is better?

Down Milling & Up Milling Definition

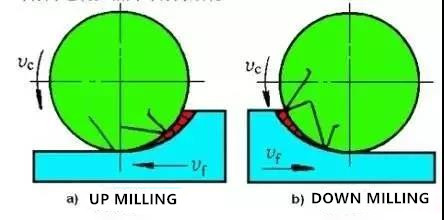

Down milling: refers to the cutting speed direction of the cutter is the same as the moving direction of the workpiece.

Up milling: refers to the direction of cutting speed opposite to the direction of movement of the workpiece.

CNC milling work, How to distinguish Down Milling and Up Milling.

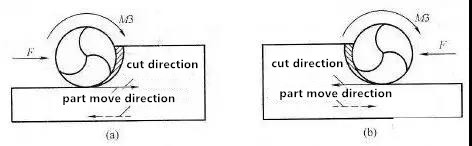

WHEN MILLING WORKPIECE OUTLINE:

Clockwise feeding and programming along the outline of the workpiece is Down milling.

Counterclockwise programming and feeding along the outline of the workpiece is Up milling.

WHEN MILLING THE INNER CONTOUR OF THE WORKPIECE:

Clockwise feeding and programming along the inner contour of the workpiece is downmilling.

Counterclockwise programming and feeding along the inner contour of the workpiece is reverse milling.

CHARACTERISTICS OF DOWN MILLING AND UP MILLING

1.In down milling, the cutting thickness of each cutter varies gradually from small to large. When the cutter teeth are in contact with the workpiece, the cutting thickness is zero. Only when the cutter teeth slip over a certain distance on the cutting surface left by the first cutter teeth and the cutting thickness reaches a certain value, the cutter teeth really start cutting. Reverse milling makes the cutting thickness gradually change from large to small, and the sliding distance of the cutter teeth on the cutting surface is also very small. Moreover, the cutter tooth travels shorter on the workpiece than the reverse milling in the forward milling. Therefore, under the same cutting conditions, the tool is easy to wear when reverse milling is used.

2.In up milling, because the direction of the horizontal cutting force acting on the workpiece by the milling cutter is opposite to the direction of the workpiece’s feed motion, the screw and nut of the worktable can always keep one side of the thread close to each other. However, it is not the same in down milling, because the direction of the horizontal milling force is the same as the direction of the workpiece’s feed motion. When the force of the cutter teeth on the workpiece is large, the worktable will move because of the gap between the screw and nut of the worktable, which not only destroys the smoothness of the cutting process, but also affects the quality of the workpiece, and is strict. The tool will be damaged when it is heavy.

3.In up milling, the cold hardening of machined surface is serious because of the large friction between the cutter teeth and the workpiece.

4.In down milling, the cutter teeth are cut from the surface of the workpiece every time, so it is not suitable for hard-skinned workpieces.

5.The average cutting thickness is large and the cutting deformation is small in forward milling, and the power consumption is less than that in reverse milling (power consumption can be reduced by 5% in carbon steel milling and 14% in hard-to-machine materials milling).

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论