Working in a mechanical factory, mechanical processing (drilling, CNC turning, CNC milling etc Machining works) occupies the majority of the workload. And the first skill to master in mechanical processing is to repair and sharpen drill bit.

The influence of sharpening drill bit in machining work.

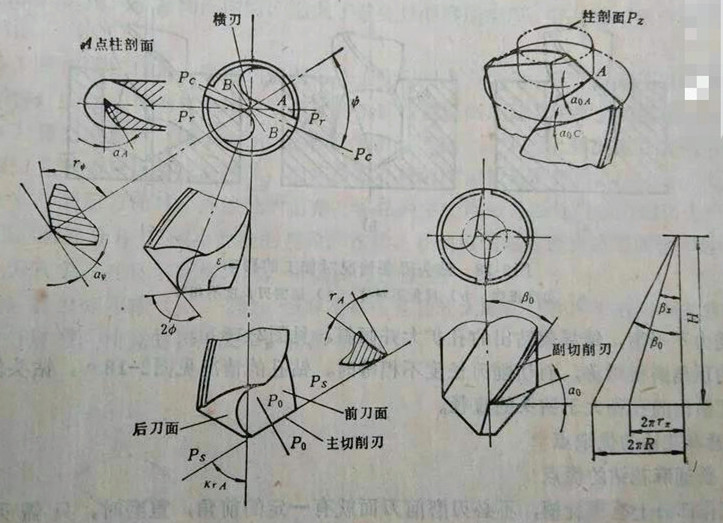

Combine the pictures in the book to explain to you.

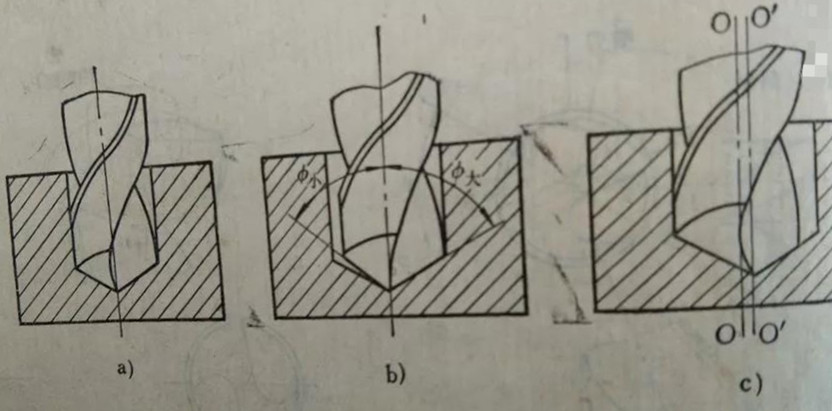

A. drill bit sharpening correct.

B. apex angle asymmetry

C. cutting edge length is unequal

It’s not difficult to sharpen a bit, but it takes a long time of practice to sharpen a good bit.

From the picture, we can see that the cutting edge of the grinding bit must be symmetrical from the top angle, otherwise the hole drilled will be larger than the diameter of the bit.

Moreover, the geometric parameters and angles in drill grinding can be neglected, because no one can accurately grasp those data by hand grinding, but the angle of drill grinding must be properly grasped.

The most important thing is the grinding of the top edge, because the two main edges of the drill will change with the angle of the top angle. From the picture, we can see that the angle of the two main edges is 118 degrees with the change of the top angle, and the angle of the two main edges is greater than 118 degrees or less than 118 degrees.

Two keys of drill bit sharpening are as follows:

- Hands should be stable and shaking should not occur on the grinding wheel.

- To grasp the grinding angle

In this way, our mechanic workers can grind out high-precision drills.

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论