In the machining process of CNC Turning Lathe, CNC router, CNC milling machine, machining work piece clamping is an important step. A suitable clamping method affect the cutting tools choose, cutting parameters setting and save machining time to save cost.

MACHINING WORK PIECE CLAMPING METHOD AND RULES:

1.MACHINING WORK PIECES CLAMPING DIRECTION:

All machining part clamp direction is: long horizontally and short vertically.

2.GEAR CLAMPING:

The clamping height should not be less than 10 mm. The clamping height and the machining height must be specified when processing the workpiece. The machining height should be about 5 mm higher than the plane of the vise in order to ensure its firmness without harming the vise. This kind of clamping belongs to general clamping. The clamping height is also related to the size of the work-piece. The larger the work-piece, the higher the clamping height.

3.SPLINT CLAMPING:

Splint code is used on the workbench, and workpiece is locked on the splint by screw. This clamping is suitable for work pieceswith insufficient clamping height and larger machining force. Generally, medium and large workpieces have better effect.

4.CODE IRON CLAMPING:

when the machining part is large and the clamping height is insufficient, and silk reeling is not allowed to be locked at the bottom, the code iron clamping is used. This kind of clamping needs to be twice clamped. Firstly, four corners are coded and other parts are machined, then four sides are coded and four corners are machined. When clamping twice, do not let the work piece loose. You can code two sides first and machine the other two sides.

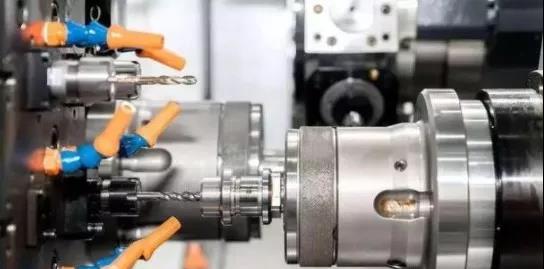

Cutting Tool Clamping Requirement:

Cutting Tool clamping: the diameter is more than 10 mm, the clamping length is not less than 30 mm. The diameter is less than 10 mm, the clamping length is not less than 20 mm. The clamping of cutters should be firm, and the cutters should be strictly protected from collision and directly inserted into the workpiece.

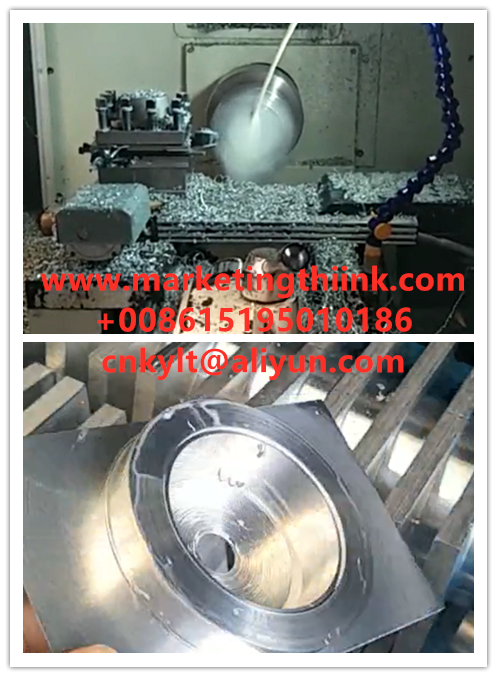

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论