Different Stainless steel types have different characteristics and usages.In CNC machining process, stainless steel turned part or milling parts are widely be used in machine manufacturing or other industries. Also, in different county, it be classified into to different serious. This article has a detail statement for stainless steel.

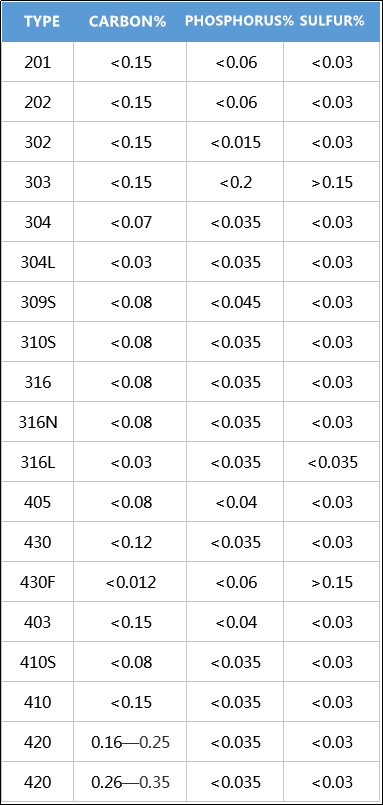

Sulphur and Phosphorus Contents in Stainless Steel

The sulphur content of steel should not exceed 0.05%, and the phosphorus content of general steel should be limited to less than 0.045%.

So the content of sulfur and phosphorus is an important index.

CARBON STRUCTURAL STEELS AND HIGH QUALITY CARBON STRUCTURAL STEELS ARE CLASSIFIED:

- High quality steel: Steel with sulfur and phosphorus content not exceeding 0.04%

- High quality steel: Steel with sulfur content less than 0.03% and phosphorus content less than 0.035%

- Super quality steel: Steel with sulfur and phosphorus content not exceeding 0.025%

The content of sulfur and phosphorus in common stainless steel is as follows:

Common stainless steel types or models

Commonly used digital symbols for stainless steel models are 200 series, 300 series and 400 series. They are the representation of the United States Stainless steel types, such as 201, 202, 302, 303, 304, 316, 410, 420, 430, etc. Chinese stainless steel models are represented by elemental symbols plus numbers, such as 1Cr18Ni9, 0Cr18Ni9, 00Cr18Ni9, 1Cr17, 3Cr13, 1Cr17M. N6Ni5N, etc. Numbers denote the corresponding element content.

200 SERIES: CHROMIUM-NICKEL-MANGANESE AUSTENITIC STAINLESS STEEL

300 SERIES: CHROMIUM-NICKEL AUSTENITIC STAINLESS STEEL

STAINLESS STEEL 301:

It has good ductility and can be used for moulding products. It can also be hardened by machine speed. Good weldability. The wear resistance and fatigue strength are better than 304 stainless steel.

STAINLESS STEEL 302:

Corrosion resistance is the same as 304, and its strength is better because of its relatively high carbon content.

STAINLESS STEEL 302B:

It is a stainless steel with high silicon content. It has high oxidation resistance at high temperature.

STAINLESS STEEL 303:

By adding a small amount of sulfur and phosphorus to make it more machined.

STAINLESS STEEL 303SE:

It is also used to make parts requiring hot upsetting, because under such conditions, this stainless steel has good hot workability.

STAINLESS STEEL 304:

18/8 stainless steel. GB is 0Cr18Ni9. 309: It has better temperature resistance than 304.

STAINLESS STEEL 304L:

It is a variant of 304 stainless steel with low carbon content. It is used for welding occasions. Lower carbon content minimizes the amount of carbides precipitated in the heat affected zone near the weld, and the precipitation of carbides may lead to intergranular corrosion (welding corrosion) of stainless steel in some environments.

STAINLESS STEEL 304N:

A stainless steel containing nitrogen. Nitrogen is added to improve the strength of the steel.

STAINLESS STEEL 305 AND 384:

High nickel content, low work hardening rate, suitable for various occasions requiring high cold formability.

STAINLESS STEEL 308:

Used for making welding rods.

STAINLESS STEEL 309, 310, 314 AND 330:

Nickel and chromium contents are relatively high in order to improve the oxidation resistance and creep strength of steel at high temperature. While 30S5 and 310S are variants of 309 and 310 stainless steel, the difference is only that the carbon content is low, in order to minimize the carbides precipitated near the weld. 330 stainless steel has very high carburizing resistance and thermal shock resistance.

STAINLESS STEEL 316 AND 317:

Containing aluminium, the pitting corrosion resistance of 304 stainless steel in marine and chemical environment is much better than that of 304 stainless steel. Among them, 316 stainless steel includes low carbon stainless steel 316L, high strength stainless steel 316N containing nitrogen and free cutting stainless steel 316F with high sulphur content.

STAINLESS STEEL 321, 347 AND 348:

Stainless steel stabilized by titanium, niobium plus tantalum and niobium, respectively, is suitable for high temperature welding components. 348 is a kind of stainless steel suitable for nuclear power industry, which limits the amount of tantalum and drill.

400 SERIES: FERRITE AND MARTENSITE STAINLESS STEEL

STAINLESS STEEL 408:

Good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni

STAINLESS STEEL 409:

The cheapest model (Anglo-American), usually used for automotive exhaust pipes, is ferritic stainless steel (chromium steel)

STAINLESS STEEL 410:

Martensite (high strength chromium steel), good wear resistance, poor corrosion resistance. 416: Adding sulphur improves the processability of the material.

STAINLESS STEEL 420:

“Tool grade” martensitic steel, similar to Brinell high chromium steel, the earliest stainless steel. It’s also used for surgical knives. It can be made very bright.

STAINLESS STEEL 430:

Ferritic stainless steel for decorative purposes, such as automotive accessories. Good formability, but poor temperature resistance and corrosion resistance

STAINLESS STEEL 440:

High strength cutting tool steel, slightly higher carbon content, after appropriate heat treatment can obtain higher yield strength, hardness can reach 58HRC, belongs to the hardest stainless steel. The most common example of application is the razor blade. There are three common models: 440A, 440B, 440C, and 440F (easy-to-process type).

500 SERIES: HEAT RESISTANT CHROMIUM ALLOY STEEL

600 SERIES: MARTENSITE PRECIPITATION HARDENING STAINLESS STEEL

STAINLESS STEEL 630:

The most commonly used type of precipitation hardening stainless steel, also known as 17-4; 17% Cr, 4% Ni

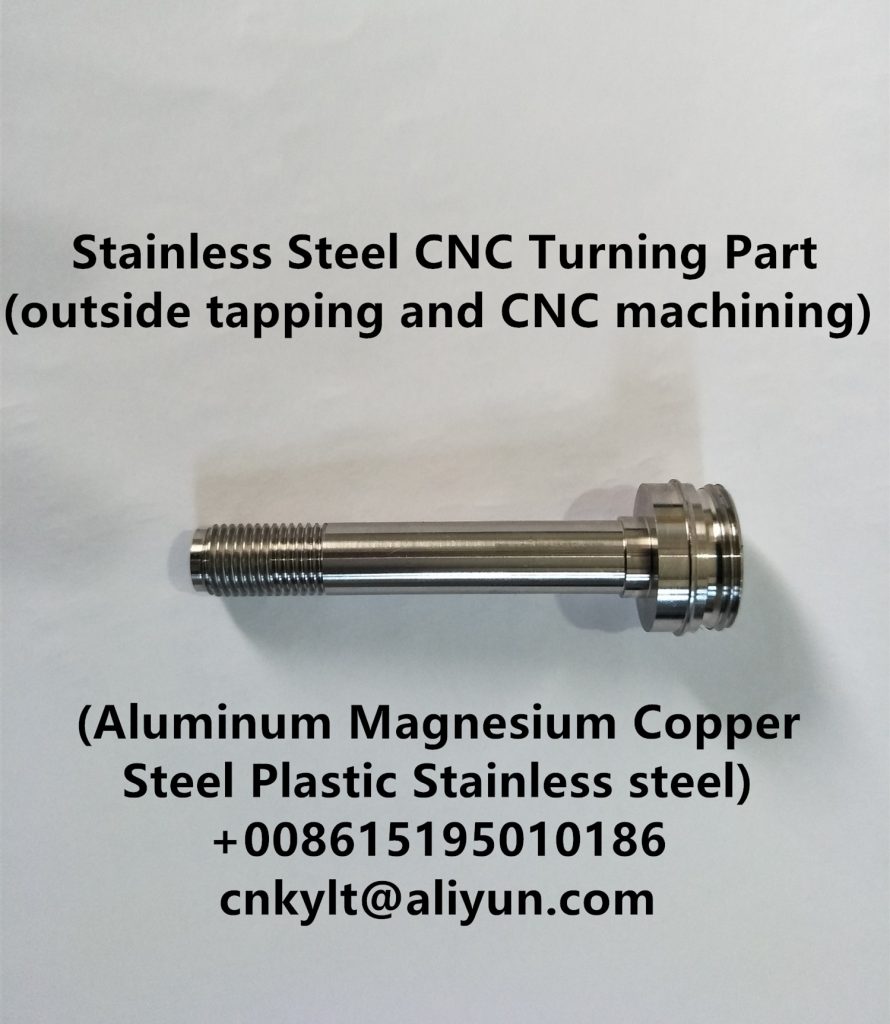

More information and Stainless steel CNC machining (turned part, milling part, prototype) services, please feel free contact: cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论