To classify CNC machine as per function level of CNC system.

According to the function level of CNC system, CNC system is usually divided into three categories: low, medium and high. This kind of classification is widely used in China. The boundaries of low, medium and high grades are relative, and the standards of division will be different in different periods. In terms of the current development level, various types of CNC systems can be divided into three categories: low, medium and high-end according to some functions and indicators. Among them, the middle and high-grade are generally called full function CNC or standard CNC.

(1) metal cutting CNC machine

Refers to the use of turning, milling, collision, reaming, drilling, grinding, planing and other cutting processes of CNC machine tools. It can be divided into the following two categories.

① common CNC machine tools such as CNC lathe, CNC milling machine, CNC grinding machine, etc.

② the main feature of machining center is the tool library with automatic tool change mechanism and the workpiece passes through once. After clamping, through automatic replacement of various cutting tools, various processes such as milling (turning) key, reaming, drilling, tapping and other processes are continuously processed on the same machine tool for each processing surface of the workpiece, such as (building / milling type) processing center, turning center, drilling center, etc.

(2) metal forming CNC machine

It refers to the numerical control machine tool with extrusion, punching, pressing, drawing and other forming processes, commonly used including numerical control press, numerical control bending machine, numerical control bending machine, numerical control spinning machine, etc.

(3) special processing CNC machine

It mainly includes CNC WEDM, CNC EDM forming machine, CNC flame cutting machine, CNC laser processing machine, etc.

(4) measurement and drawing CNC machine

There are mainly three coordinate measuring instruments, CNC tool setting instruments, CNC plotter, etc

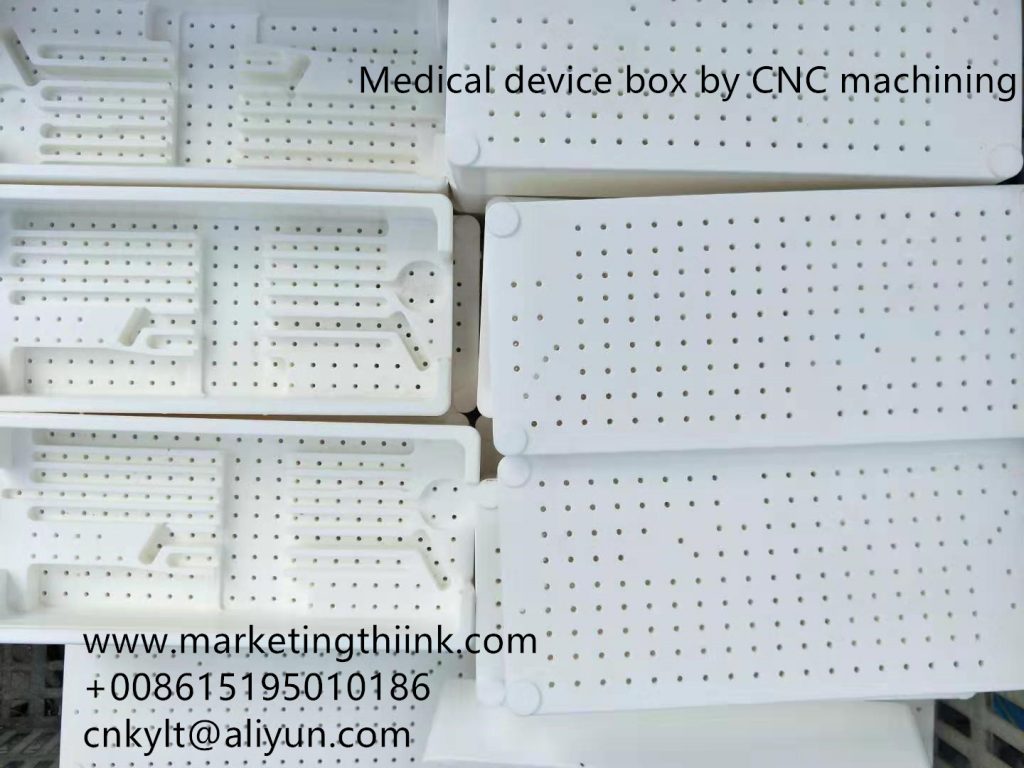

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making,Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论