Operating CNC machining center, or CNC router, always need to set cutting tool and change cutting tool to meet manufacturing requirement.

“How to set and change the cutting tool in machining center?” is the common question.

The cutting tool setting

The tool setting point of CNC machining center is the reference point used to determine the position of workpiece coordinate system in the machine coordinate system after the workpiece is aligned and clamped on the machine.

Tool setting point can be selected on workpiece or clamping positioning element. There must be an accurate, reasonable and simple position corresponding relationship between the tool setting point and the workpiece coordinate point, which is convenient to calculate the position of the workpiece coordinate point on the machine tool (the machine coordinate of the workpiece coordinate point). The tool setting point should preferably coincide with the workpiece coordinate point.

Tool change point

Tool change point: the machining center has a tool magazine and an automatic tool change device, which can change the tool automatically according to the needs of the program. The tool change point shall be in the position where there is no collision and interference between workpiece, fixture, tool and machine tool during tool change, and the tool change point of machining center is usually fixed.

Horizontal tool setting (x, y coordinates):

(1) tool setting of lever dial indicator: the tool setting point is the center of cylindrical hole;

(2) tool setting with edge finder: round hole or datum edge

(3) adjust the cutter by touching the cutter or trial cutting.

Tool setting in Z direction (Z coordinate):

(1) on machine tool setting: use Z-direction setter to set the tool.

(2) pre adjustment of external tools + on-board tool setting.

(3) tool setting by external tool setting instrument: measure the diameter, length, blade shape and angle of the tool.

(4) the problem of tool setting in multi position machining of horizontal machining center.

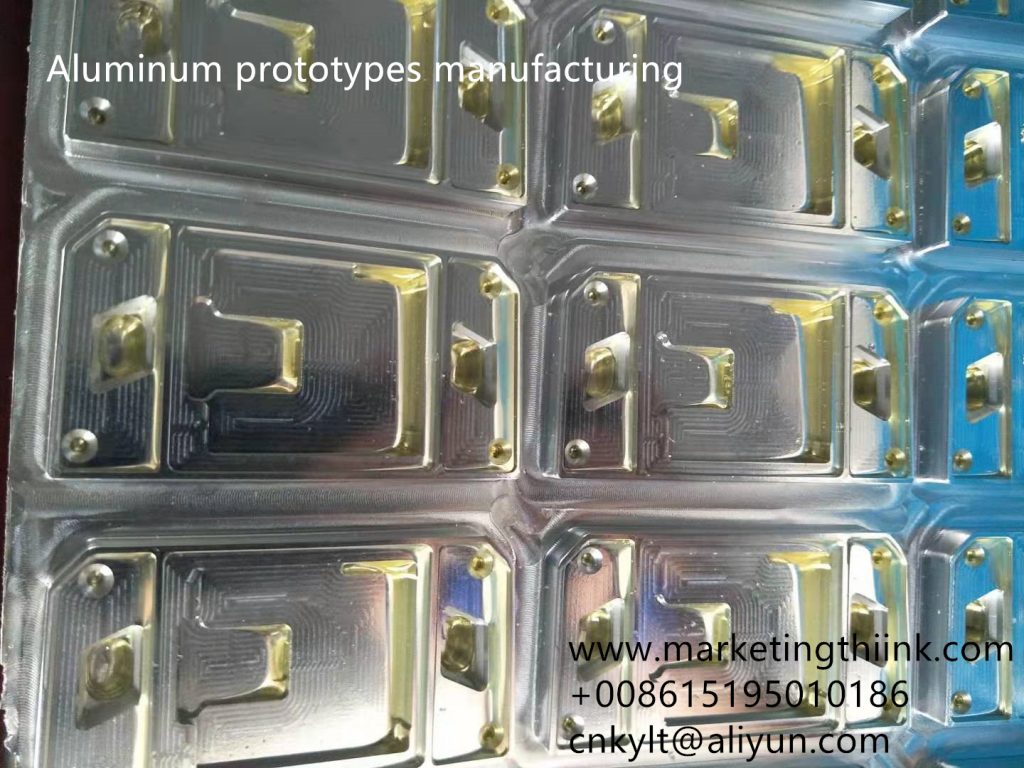

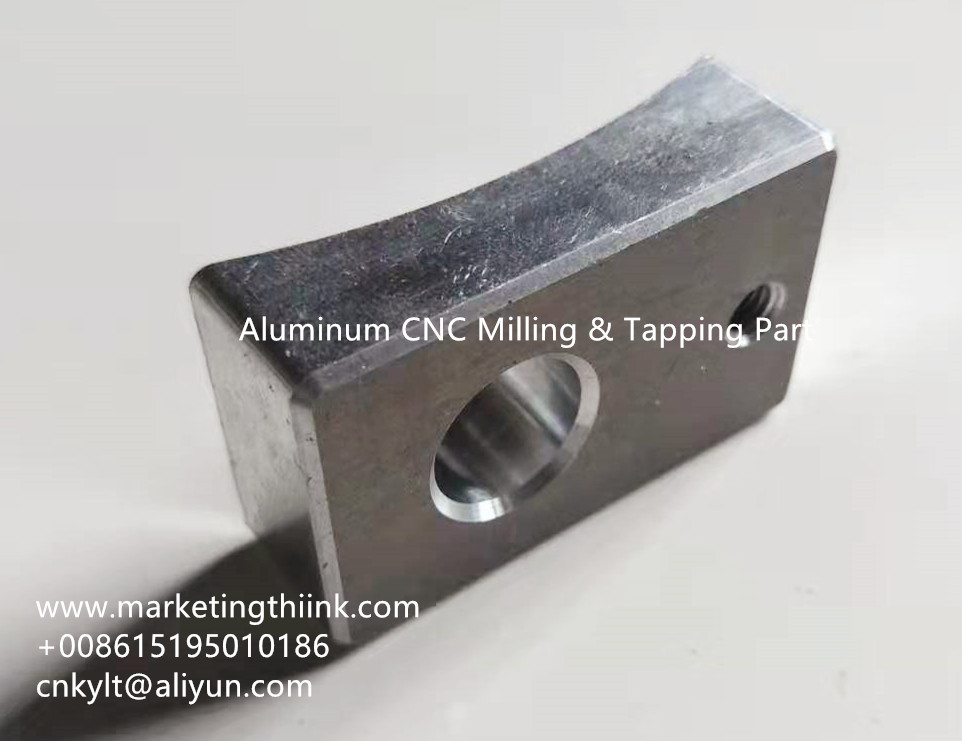

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论