When the NC lathe is machining, the metal machining parts have Vibration Lines.

When making a precision machining by lathe, the turned part doesn’t have a beautiful appearance. You need to polish it quietly with fine sandpaper or oilstone. Especially for the products with high precision and need to be electroplated, it is necessary to be very careful at this time, otherwise it is easy to form waste products.

Many factors that can cause MACHINING VIBRATION LINES, we can first analyze from these aspects:

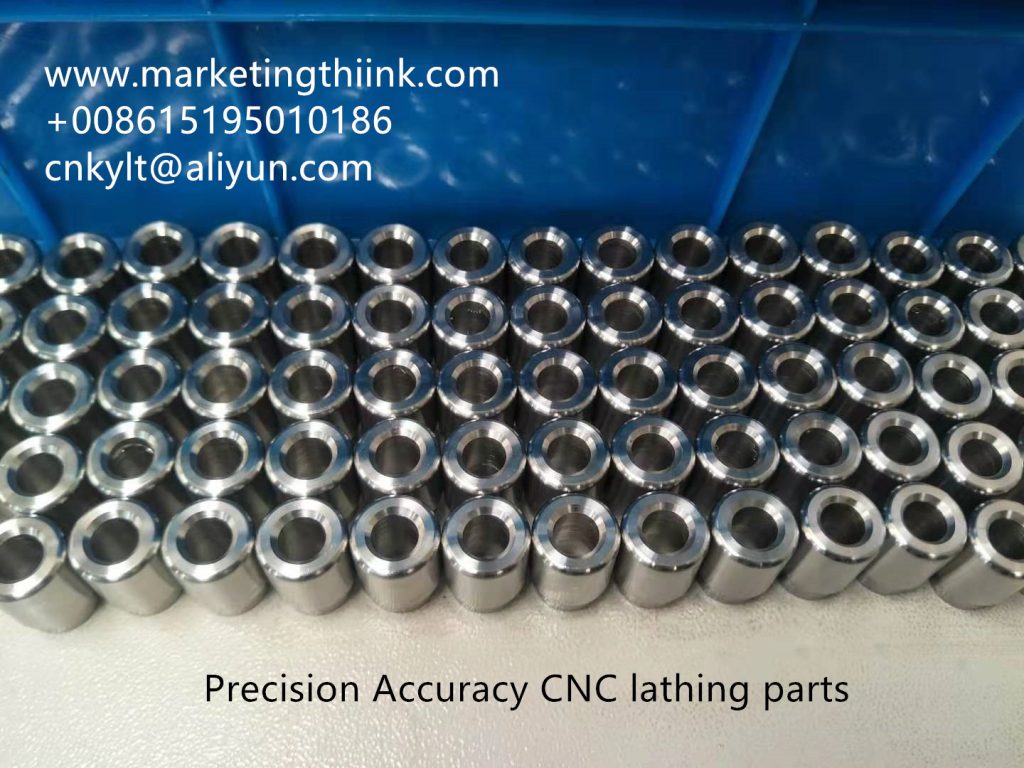

First of all, to judge whether there is “vibration pattern”, the general rule is: there is a horizontal pattern, as shown in the figure, which appears to be a spiral pattern with large spacing.

- It is necessary to know whether the workpiece will be vibrated when it is processed once or after it is processed twice.

- If the machine is hit, it is easy to have the effect of z-axis screw rod and main shaft, which will lead to vibration pattern.

- Whether the rotation speed of the machine tool is within the reasonable range, and change the rotary feed into the sub feed in sequence. (due to the large rotating speed of the machine tool, the feed speed is uneven, and it is accelerating and decelerating from time to time. If the accuracy of the private service unit and the actuator of the machine tool is not high enough, it is easy to form ripples.)

- Rigidity mismatch of machining center system driver

- Fixed rigidity of workpiece itself or workpiece

Some smaller and thinner machined parts can not be fixed in the fixture reasonably due to the lack of rigidity or the shape of the workpiece.

- The z-axis screw rod supports the bearing, and the loose nut is easy to cause vibration.

- If the tip arc is too large, and the blade is too wide, it is easy to have transverse lines. Sharpening can reduce vibration, or sharpen the transition blade.

- The unbalanced mass caused by external factors causes the occurrence of vibration striation due to the action of unbalanced centripetal force during rotation. Especially in high-speed machining, the dynamic balance of workpiece has a great influence.

- The selection of cutting parameters includes: cutting speed, feed, feed amount and cooling mode, etc.

- The guide rail of machine tool in machining center is loose.

The occurrence of machining vibration pattern should be avoided from the source, and vibration should be avoided as far as possible when cutting workpiece.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论