Screw thread gauge usage : to be used to check thread after machining to meet machined parts manufacturing tolerances.

The usage of thread gauge (sub-screw, and screw coil)

A. UNDERSTANDING THREAD GAUGE STRUCTURE

1) The T (through) end is usually longer than the Z (stop) end.

2) There is a ditch in the middle of the British system.

3) Generally hardened (quenched) steel grinding, very brittle fall on the ground will break;

4) After long-term use, it will wear and tear. Generally, it needs to be re-examined more than 1000 times.

B. USAGE OF SCREW THREAD GAUGE

Only those who pass the quality assurance inspection or qualified labels (attached to boxes) can be used.

Long-term use must be used about 10,000 times (can be estimated) after inspection qualified reuse.

When use screw thread gauge check the machined parts thread hole. With the gloved thumb, index finger clamping light rotation, avoid vigorous, then T (through) end is qualified, Z (stop) end into 1 ~ 2 teeth, no longer qualified, must not use vigorous, after using the thread gauge, must be clean with clean soft cloth thread gauge (sample ring or column) to be wiped, coated with rust-proof oil back to the box.

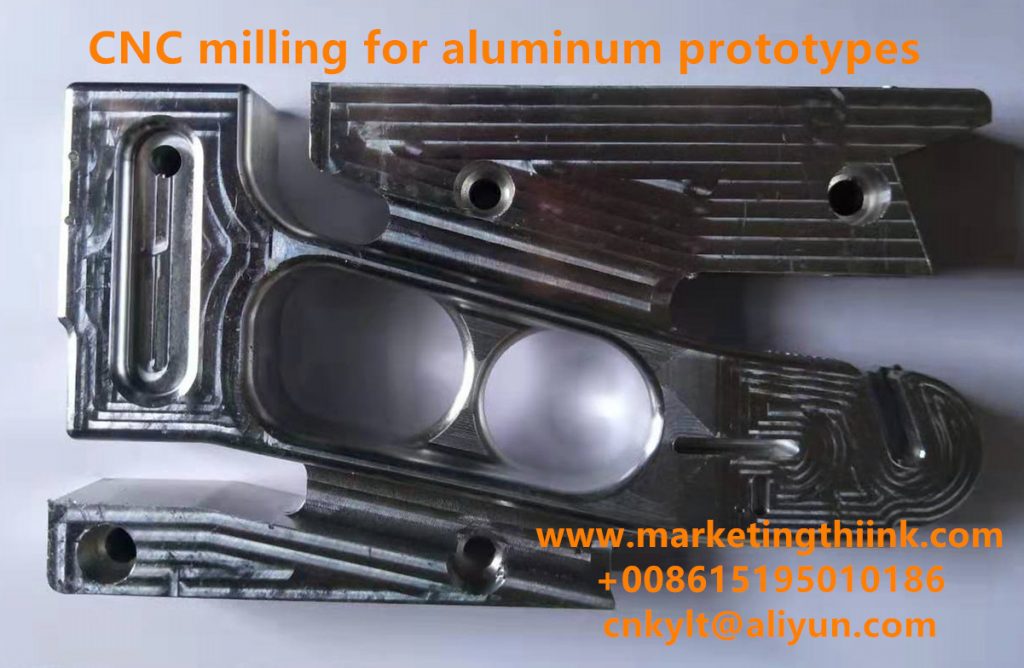

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论