Machining tolerance range is the key elements of used to judge the machined parts quality. For different work-piece, tolerance requirement are different, in order to avoid machining failure, machining tolerance table is used to specified normal machining accuracy class.

MACHINING TOLERANCE TABLE

Free tolerance table of machining

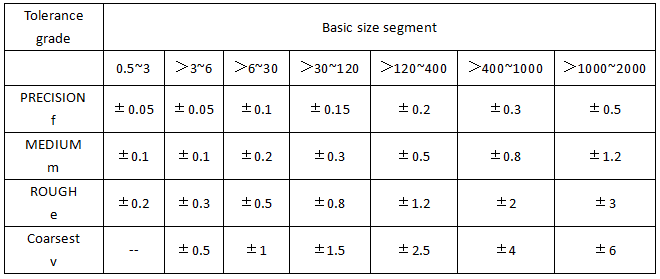

1. LIMIT DEVIATION VALUE OF LINEAR DIMENSION (GB / T1804-2000) (MM)

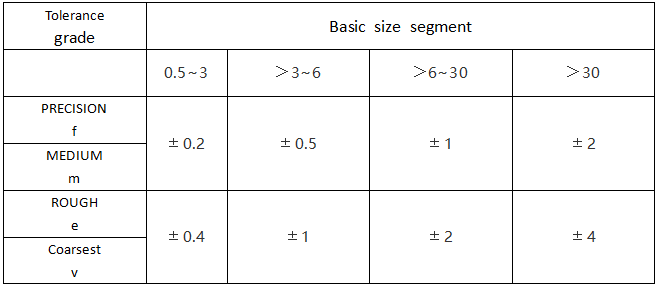

2. LIMIT DEVIATION OF ROUNDING RADIUS AND CHAMFER HEIGHT (GB / T1804-2000) MM

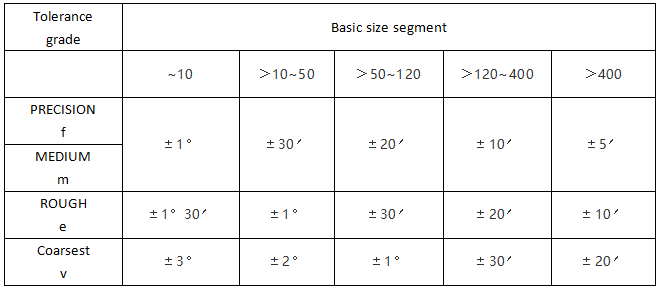

3. LIMIT DEVIATION VALUE OF ANGLE DIMENSION (GB / T1804-2000)

4. UNDECLARED FORM AND POSITION TOLERANCE SHALL BE IN ACCORDANCE WITH GB / T1184-K.

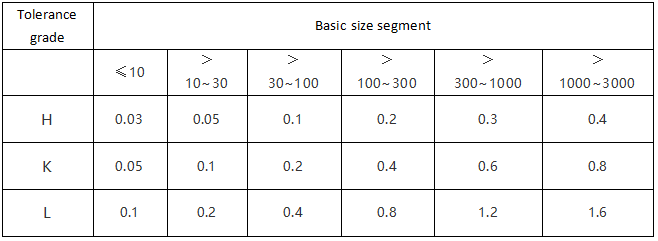

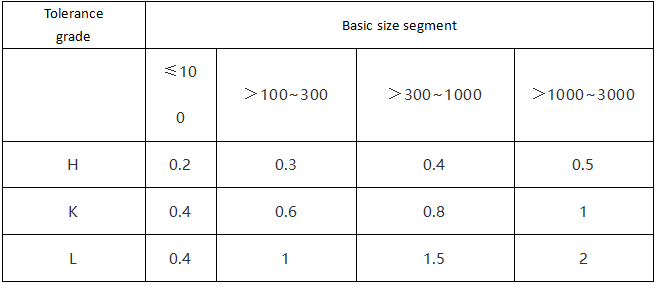

4.1 unspecified tolerance value of straightness and flatness (GB / t1184-1996) (mm)

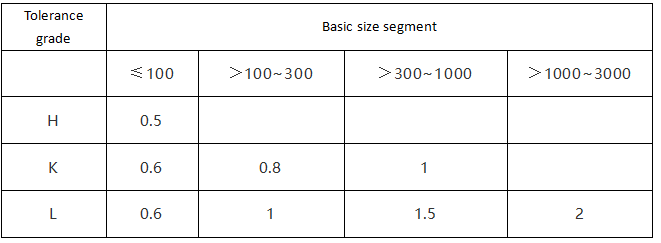

4.2 unspecified tolerance value of perpendicularity (GB / t1184-1996) (mm)

4.3 unspecified tolerance value of symmetry (GB / t1184-1996) (mm)

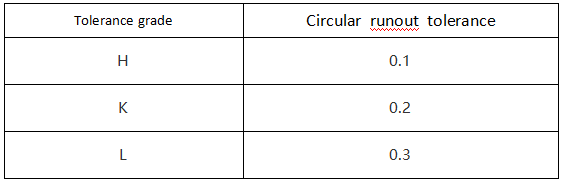

4.4 unspecified tolerance value of circular runout (GB / t1184-1996) (mm)

Surface roughness of machining parts

The surface of parts shall be marked with roughness grade. If more surfaces have the same surface roughness level, mark them in the upper right corner of the drawing, and add “others”.

The selection of roughness grade can generally be determined according to the working requirements and dimensional accuracy grade of each surface. Under the condition of meeting the working requirements, the grade shall not be increased at will.

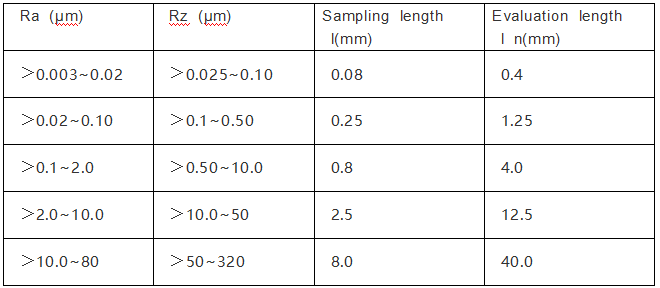

1) SELECTION VALUE OF SAMPLING LENGTH AND EVALUATION LENGTH (GB / T1031-1995)

2) VALUE OF ARITHMETIC MEAN DEVIATION RA OF CONTOUR (GB / T1031-1995) (Μ M)

Series 1 0.012, 0.025, 0.050, 0.10, 0.20, 0.40, 0.80, 1.60, 3.2, 6.3, 12.5, 25, 50, 100

Series 2 0.008, 0.010, 0.016, 0.020, 0.032, 0.040, 0.063, 0.080, 0.125, 0.160, 0.25, 0.32, 0.50, 0.63, 1.0, 1.25, 2.0, 2.5, 4.0, 5.0, 8.0, 10.0, 16.0, 20, 32, 40, 63, 80

Note: try to choose Series 1

3) VALUE OF MAXIMUM HEIGHT RZ OF CONTOUR (GB / T1031-1995) (Μ M)

Series 1 0.025, 0.050, 0.100, 0.20, 0.40, 0.80, 1.60, 3.2, 6.3, 12.5, 25, 50, 1002004008001600,

Series 2 0.032, 0.040, 0.063, 0.080, 0.125, 0.160, 0.25, 0.32, 0.50, 0.63, 1.0, 1.25, 2.0, 2.5, 4.0, 5.0, 8.0, 10.0, 16.0, 20, 32, 40, 63, 80, 125, 160, 250, 320, 500, 630

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论