In Plastic molding and die casting process, Mold temperature affect the injection parts quality.

Normally, we use Water Cooling method and Temperature machine to control the mold temperature.

Temperature machine is used to heat the mould and maintain its working temperature, to ensure the quality of injection parts stable and optimize processing time. In the injection process, the temperature of the mould plays a decisive role in the quality of the injection parts and the injection time. Specifically as follows:

To achieve thermal balance on the surface of the mould, the injection moulds with stable quality can be produced continuously.

Thermal balance control of injection moulds and heat conduction of injection moulds is the key to the production of injection moulds. Inside the die, heat from plastic is transferred to the material and the steel of the die by thermal radiation, and to the heat conducting fluid by convection. In addition, heat is transferred to the atmosphere and the die base through thermal radiation. The heat absorbed by the heated fluid is taken away by the thermostat. The thermal balance of the die can be described as P=Pm-Ps. In the model, P is the heat carried by the mould temperature machine; Pm is the heat introduced by the plastic; Ps is the heat emitted from the mould to the atmosphere.

The main purpose of controlling the temperature of the die is to heat the die to the working temperature and keep the temperature of the die constant at the working temperature.

The cycle time can be optimized to ensure the high quality and stability of the injection parts. Mold temperature will affect surface quality, fluidity, shrinkage, injection cycle and deformation. Excessive or insufficient die temperature will have different effects on different materials. For thermoplastics, higher die temperature usually improves surface quality and fluidity, but prolongs cooling time and injection cycle.

A lower die temperature will reduce the shrinkage in the die, but it will increase the shrinkage of the injection parts after demoulding. For thermosetting plastics, higher die temperature usually reduces the cycle time, which is determined by the cooling time of the parts. In addition, in plastic processing, higher die temperature will also reduce plasticizing time and cycle times.

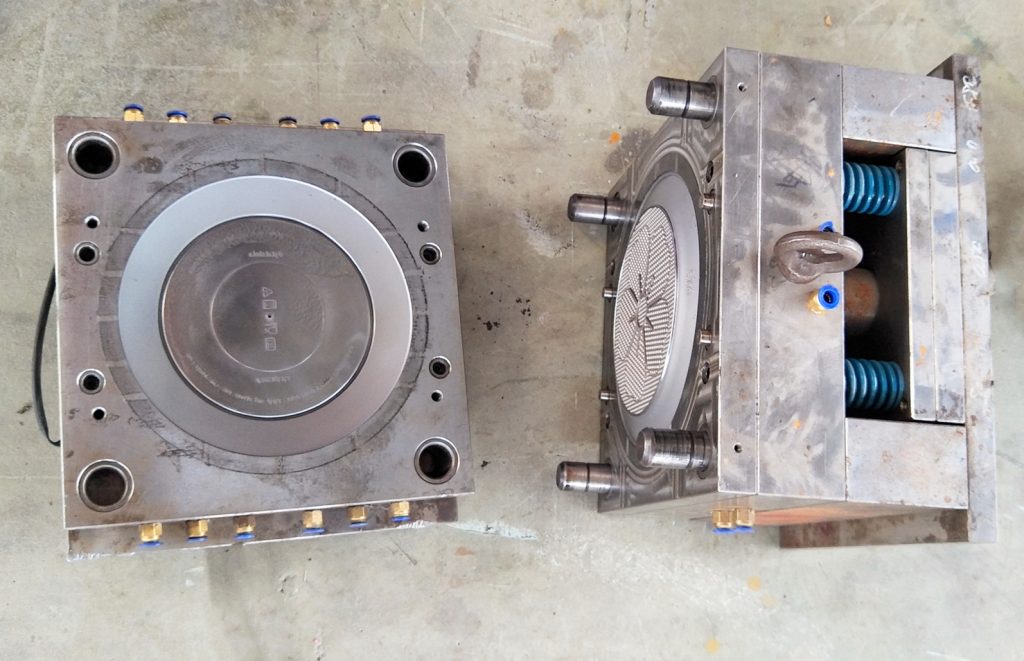

Preparatory condition temperature control system for effective control of mould temperature is composed of three parts: mould, mould temperature machine and heat conducting fluid.

In order to ensure that heat can be added to or removed from the die, the system must meet the following conditions: first, in the die, the surface area of the cooling passage must be large enough, and the diameter of the flow passage must match the capacity of the pump. The temperature distribution in the cavity has a great influence on the deformation and internal stress of the part. Reasonable setting of cooling runner can reduce the internal stress and improve the quality of injection parts. It can also shorten cycle time and reduce product cost. Secondly, the mould temperature machine must be able to keep the temperature of the heat conducting fluid in the range of 1℃ ~3℃, which is determined according to the quality requirements of the injection parts. Thirdly, the heat conducting fluid must have good heat conductivity, and most importantly, it should be able to import or export a large amount of heat in a short time. From the thermodynamic point of view, water is obviously better than oil.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论