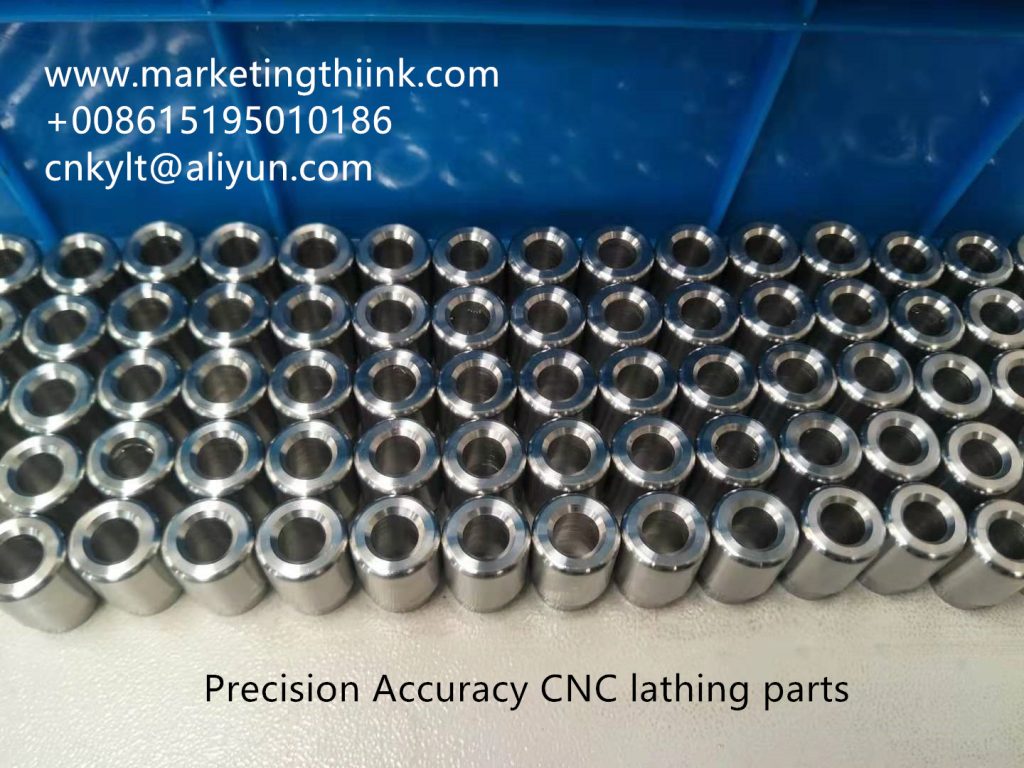

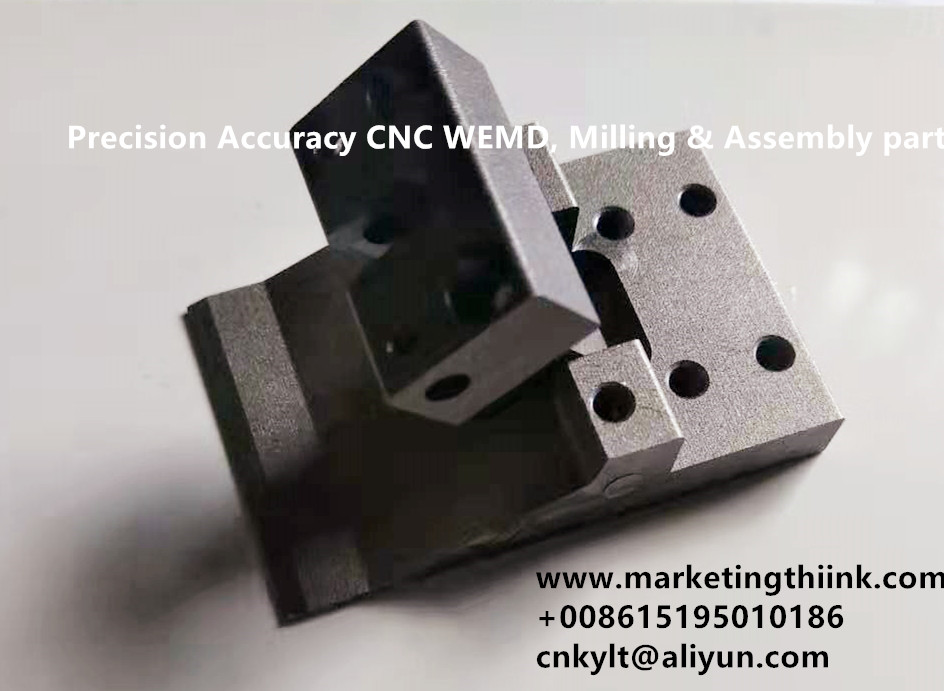

The machining parts quality includes Machining precision accuracy and Surface quality. Especially for NC lathing parts and CNC machining parts, they are require tight tolerance and good surface.

What is machining precision accuracy?

Machining accuracy refers to the degree of conformity between the actual value and the ideal value of the geometric parameters (size, geometry and mutual position) of the parts after machining. The deviation between the actual value and the ideal value is the machining error. The machining error reflects the machining accuracy.

THE MACHINING ACCURACY OF PARTS INCLUDES THREE ASPECTS:

- Dimensional accuracy

- Geometric accuracy

- Mutual position accuracy

There is a connection between these three factors.

In machining, the formation of the size, geometry and relative position between the surfaces of the parts mainly depends on the mutual position relationship between the workpiece and the tool in the process of cutting movement. The workpiece and cutter are installed on the fixture and machine tool, and are constrained by the fixture and machine tool.

In machining, machine tool, fixture, cutter and workpiece constitute a complete system, which is called process system. The problem of machining accuracy of parts is essentially the accuracy of the whole process system.

Therefore, the designer should reasonably specify the machining parts precision accuracy according to their usage. According to the design requirements and production conditions, the technologists should adopt appropriate process methods to improve the productivity and reduce the cost as much as possible on the premise of ensuring the processing accuracy.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论