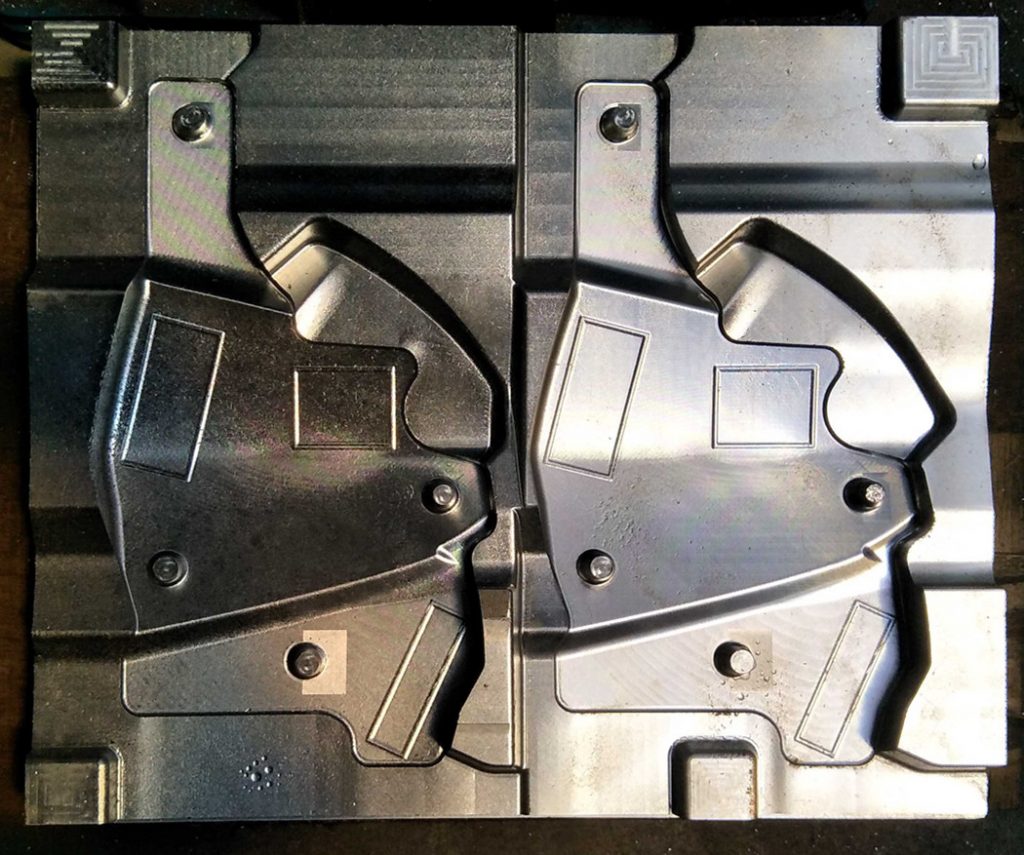

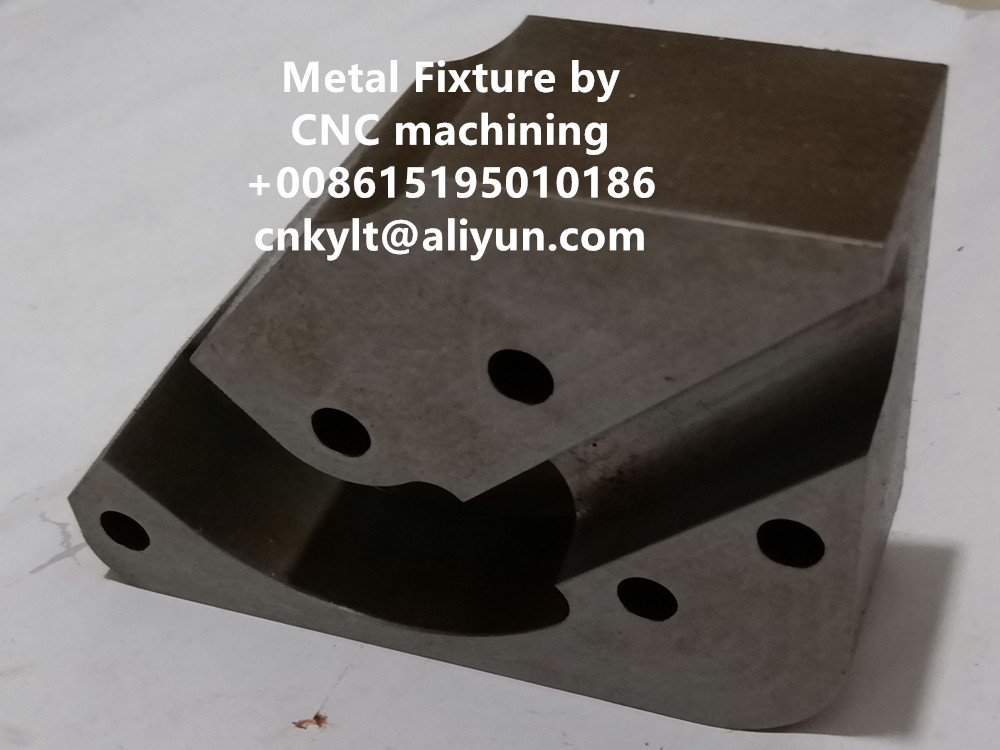

Steel machining parts, Injection mold or Dies making, Quenching and tempering be required to treat on steel block to make them more hard and with long using life.

Quenching and tempering: The heat treatment method of high temperature tempering after quenching is called quenching and tempering. High temperature tempering refers to tempering between 500 and 650 C. Tempering and tempering can make the properties and materials of steel adjusted to a great extent. Its strength, plasticity and toughness are good, and it has good comprehensive mechanical properties.

Tempered sorbite was obtained after quenching and tempering. Tempered sorbite is formed when martensite is tempered. It can be distinguished more than 500 to 600 times under optical metallographic microscope. It is a composite structure with carbide (including cementite) spheres distributed in ferrite matrix. It is also a tempering structure of martensite, a mixture of ferrite and granular carbide. At this time, the ferrite has almost no carbon supersaturation, and the carbides are also stable carbides. It is a balanced structure at room temperature.

There are two kinds of quenched and tempered steels: carbon quenched and tempered steel and alloy quenched and tempered steel. Whether carbon steel or alloy steel, its carbon content is strictly controlled. If the carbon content is too high, the strength of the workpiece after quenching and tempering is high, but the toughness is not enough, for example, the carbon content is too low, the toughness is improved and the strength is insufficient. In order to obtain good comprehensive properties of quenched and tempered parts, the carbon content is generally controlled at 0.30-0.50%.

During quenching and tempering, the whole section of the workpiece is required to be quenched thoroughly, so that the microstructure of the workpiece is mainly fine needle like quenched martensite. Microstructure of homogeneous tempered sorbite was obtained by high temperature tempering. It is impossible for small factories to do metallographic analysis in each furnace. Generally, hardness testing is only done. That is to say, the hardness after quenching must reach the hardness of the material after quenching, and the hardness after tempering should be checked according to the graph requirements.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论