When a metal work-piece be machined, Correct tapping method insure the machining parts with good tolerance and correct assembly.

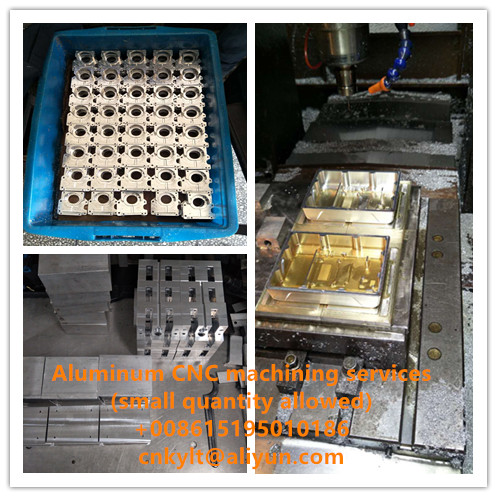

KYLT provide all kinds metal Machining services: WEDM, EDM, CNC LATHING, CNC MILLING, MAGNESIUM/ALUMINUM/PLASTIC PROTOTYPES manufacturing.

Choosing the right tap

There is one attack, two attacks, three attacks, generally we use the third attack, unless very thick plate, it is divided into one, two, three attacks generally with machine taps (only once).

Tap shapes can be divided into:

1.Ordinary wire Tap

2.Spiral tap: more expensive, but good chip removal, high efficiency;

3.Head tap: expensive, but good chip removal, high efficiency;

4.Chip-free tap: The thin material (usually below 3M/M) is extruded into screw shape by extrusion, so the hole is larger than that of common tapping and screw tapping. For example, M3-0.5 common and screw tapping common iron plate teeth drill 2.6 holes, but no chips tapping, drill 2.78-2.8 holes.

Thick plate Tapping (above 3M/M)

Before tapping, the burr of the hole in the plate should be scratched off by the drill bit, but it must not be changed into chamfer, otherwise the thickness of the plate will slide because of chamfering, which will result in fewer screw teeth.

Tapping angle

The tap must be perpendicular to the workpiece in tapping.

Debris clean in tapping process

When tapping, the iron (aluminium) debris on the surface must be removed by brush (toothbrush) or high-pressure air cleaning.

Cutting fluid use for tapping

When making thread, clean oil must be applied instead of dirty oil containing iron scraps or other impurities.

Drill hole before machining thread

Before tapping, the aperture must be found correctly, and the thickness of the plate and the material all affect the aperture.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论