The machining quality of machined parts includes not only the machining accuracy, but also the surface quality after machining. The working performance of mechanical products, especially its reliability and durability, largely depends on the surface quality of its main parts. With the development of science and technology, the machine is developing towards the direction of high speed and heavy load, high temperature and high pressure. And the requirements for the surface quality of parts are higher and higher.

Surface quality Concept of Machining parts

Machined parts Surface quality refers to the state of surface layer after machining, which includes surface roughness, waviness and physical and mechanical properties of surface layer.

(1) SURFACE ROUGHNESS AND WAVINESS

Surface roughness refers to the micro geometry error of machined surface. It is usually formed by the moving track of cutting tools in machining, and the ratio of wave distance to wave height is generally less than 50.

(2) PHYSICAL AND MECHANICAL PROPERTIES OF SURFACE LAYER

The surface layer is cold hardening. It refers to the phenomenon that the strength and hardness of the surface layer of the workpiece are improved after machining, also known as cold hardening or strengthening; the metallographic structure of the surface layer changes. It refers to the phenomenon that the high temperature produced in cutting (especially grinding) changes the metallographic structure of the surface metal of the workpiece and reduces the surface hardness; the residual stress of the surface layer. It refers to the residual stress on the surface layer of the workpiece caused by the cutting force and cutting heat in the cutting process, which affects the fatigue strength of the parts.

Factors affecting Machined parts surface roughness

In machining, there are two main reasons for the formation of surface roughness:

1.The cutting residual area geometric factor formed by the relative movement track of the blade and workpiece;

2.The factor physical factor related to the nature of the material to be processed and the cutting mechanism, which refers to the plastic deformation, friction, chip accretion, scale thorn and vibration in the process system.

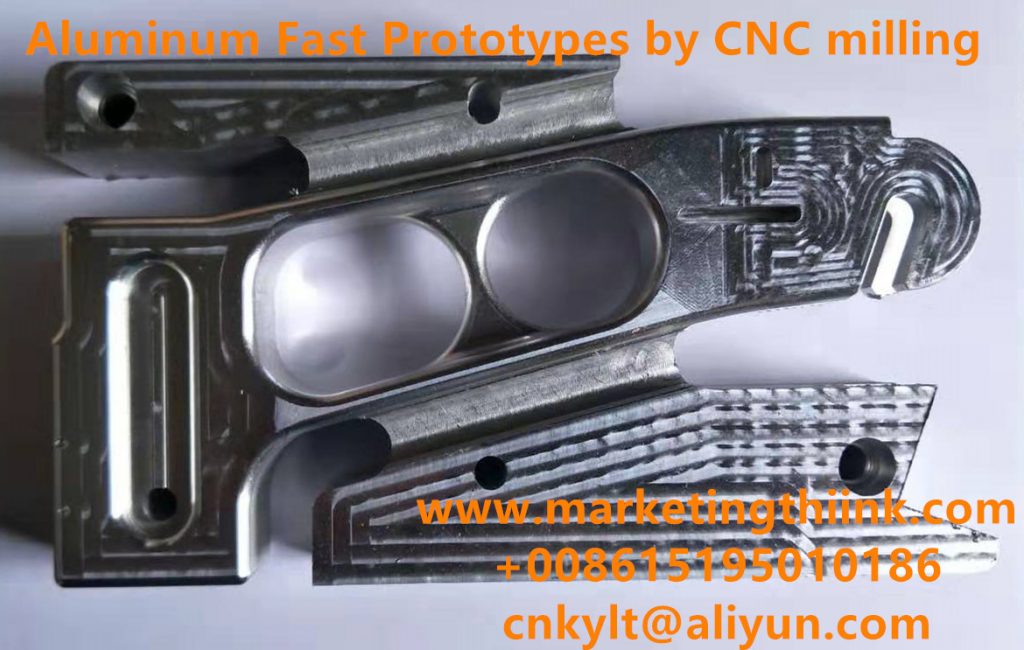

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making,Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论