This article stated 17 application skills of milling.

What is milling?

Milling is to fix the blank and use a high-speed milling cutter to cut out the required shape and features. Traditional milling is mostly used for milling simple shapes / features such as profiles and grooves. CNC milling machine can process complex shape and features.

Milling and boring machining center can be used for three-axis or multi axis milling and boring machining, for machining, mold, inspection tool, fixture, thin-walled complex surface, artificial prosthesis, blade, etc. When choosing the content of NC milling, we should give full play to the advantage and key role of NC milling machine.

In the actual production of milling, including machine tool setting, workpiece clamping, tool selection and other application skills, this issue briefly summarizes 17 key points of milling, each of which is worth your in-depth grasp.

POWER CAPACITY

Check the power capacity and rigidity of the machine to ensure that the machine can use the required milling cutter diameter.

WORKPIECE STABILITY

Workpiece clamping conditions and considerations.

OVERHANG

During machining, the tool overhang on the spindle shall be as short as possible.

SELECT THE RIGHT GEAR PITCH OF MILLING CUTTER

Use the correct pitch of milling cutter suitable for the working procedure to ensure that there is not too much blade involved in cutting, otherwise vibration will be caused.

CUTTING KNIFE

For narrow workpiece or gap milling, make sure that there is sufficient blade cutting.

BLADE SLOT TYPE SELECTION

Use positive front angle slot indexable blade as much as possible to ensure smooth cutting action and minimum power consumption.

USE CORRECT FEED

By using the recommended maximum chip thickness, ensure the correct feeding of the blade to achieve the correct cutting effect.

CUTTING DIRECTION

Use milling as far as possible.

PART CONSIDERATIONS

Workpiece material and configuration, as well as the quality requirements of the surface to be processed.

BLADE MATERIAL SELECTION

Select groove type and material according to material type and application type of workpiece.

VIBRATION DAMPING MILLING CUTTER

For a long overhang that is more than 4 times the tool diameter, the vibration trend will become more obvious, and the use of vibration damping tools can significantly improve the productivity.

MAIN DEFLECTION ANGLE

Select the most suitable main deflection angle.

MILLING CUTTER DIAMETER

Select the correct diameter according to the width of the workpiece.

POSITION OF MILLING CUTTER

Position the milling cutter correctly.

CUTTER CUT IN AND CUT OUT

It can be seen that through arc cutting, the chip thickness is always zero when the tool is withdrawn, so that higher feed and longer tool life can be achieved.

COOLANT

Use coolant only if necessary. In general, milling is better performed without coolant.

MAINTENANCE

Follow tool maintenance recommendations and monitor tool wear.

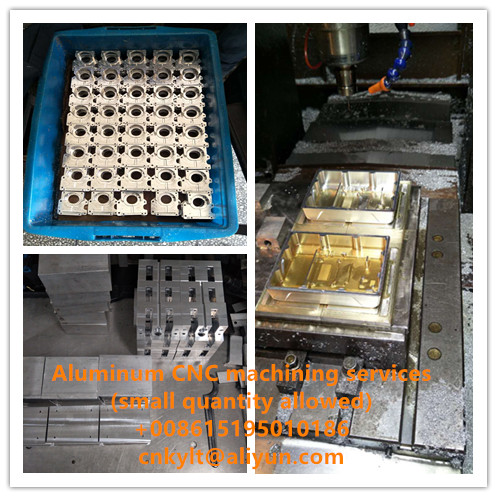

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论