Tapping method in the machining part process, which cutting oil should be used? As a machining worker, always meet the problem.

The extrusion tap is caused by the plastic flow of the material and the relationship between the extrusion and the screw thread. The performance of the cutting fluid must be more lubricity than cooling. In addition, in the way of oiling, the part in contact with the tap and the female thread should be fully forced oiling.

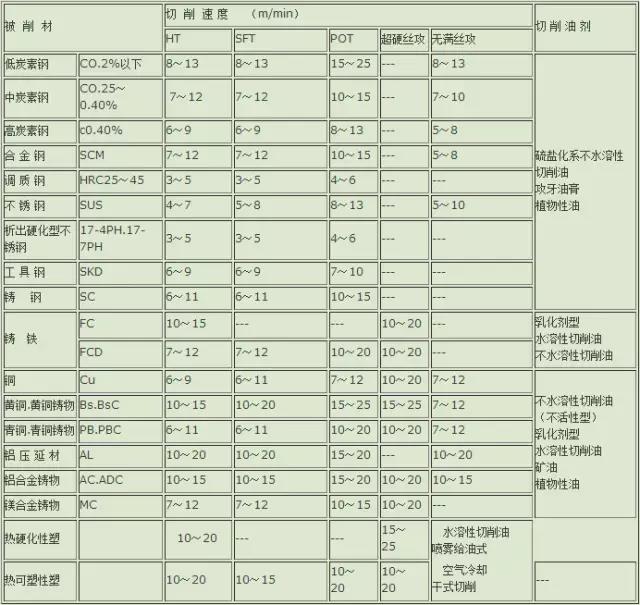

Comparison parameter table of cutting speed and cutting oil of thread tool

Must tapping oil be used in the tapping process?

In metal processing, we will encounter the process of tapping, but most people do not use tapping oil or other oil to replace it. Many factories think it’s OK to do so. Because they haven’t used real oil, they think the status quo is the best.

What is the advantage of tapping oil?

A lot of people have used manual tapping. They all know that the teeth that need to be oiled will have a high finish, and the thread engagement will also be high. It has become common sense for all of us to use oil to tap the teeth. In fact, there are three main purposes of tapping oil:

- Good tapping oil can discharge processing debris, with good chip removal performance, especially some processing materials with poor chip removal performance.

- lubrication. When the tap is cutting, if no oil is added, the surface of the thread is easy to be rough and unsmooth. Seriously affect the quality of thread

- chip removal. In the process of tapping, a large number of iron chips (mainly cutting taps) will be produced. The iron chips are easy to stick to the threaded holes and taps. At this time, a good penetration tapping oil is required.

From these points of view, tapping oil is cooling and lubricating during tapping. When the tap is cutting, the temperature of the tap rises sharply. If it is not cooled, the tap will be easily damaged, which will make the strength of the tap drop sharply and affect the durability of the tap.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论