The Aluminum CNC machined inspection fixture (checking tool) is a simple tool used by industrial production enterprises to control various sizes of products (such as aperture, space size, etc.), improve production efficiency and control quality, apply to mass-produced products, such as auto parts, to replace professional measuring tools, such as smooth plug gauges, threaded plug gauges, outside diameter caliper, etc.

With Precision CNC machining, KYLT provide all kinds of checking tools / fixutres /jigs OEM/ODM manufacture service, Which machining raw materials involve:Copper/Brass, Aluminum, Magnesium, POM(Derlin) / Teflon / NyLon / PMMA(Acrylic) / PEI (Ultem), Steel, Iron, Stainless steel etc.

CNC machining workpieces, with EDM, WEDM, Drilling, Tapping, Anodizing, Assembly etc working processes to reach .

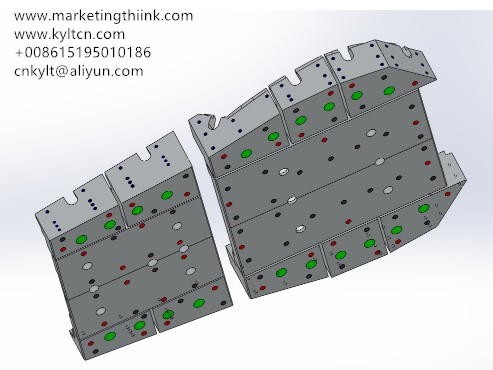

Aluminum CNC machined fixture checking tool project name:

Plantilla soldadura LTS street

- Material: Hard anodized aluminum

Checking tool Technical requirements of CNC machining:

- The side blue holes must be threaded (M6)

- The bottom black holes must be threated (M10)

- The red holes must be Ø10 H7

- The green holes must be Ø20 B7

- The yellow faces must be into +-0.1mm

- The rest of the piece +-0.25mm is enough

KYLT ONE-STOP SERVICES:

ALUMINUM ZINC/ZAMAK DIE CASTING, ALUMINUM MAGNESIUM COPPER/BRASS POM PMMA PRECISION CNC MACHINING PARTS (FIXTURE / JIGS / TOOLING / MOULDS), PLASTIC INJECTION, ETC.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论