Changzhou KYLT Co., Ltd focus on Aluminum, Zinc metal alloy Die casting services, Precision CNC machining services, Plastic Injection etc manufacturing.

KYLT production directly, our metal products and service involve:

MOULD DESIGN & MAKING

1.As per customers design and samples to make mold and produce Aluminum die casting parts or Zinc die casting parts.

2.According client’s 3D drawings or samples to make plastic molding parts.

ALUMINUM, ZINC ALLOY DIE CASTING PARTS

CNC MACHINING, DRILLING, TAPPING SERVICES:

ALUMINUM, MAGNESIUM, COPPER/BRASS, STEEL IRON, STAINLESS STEEL, PLASTIC ETC CNC PRECISION MACHINING PARTS

1.Aluminum alloy CNC milling part

2.Magnesium Alloy CNC machining part

3.Copper, Brass CNC milling machined part

4. Steel parts milled by CNC machine center

5.Stainless steel part by CNC milling

6.Plastic material CNC milling

7.Aluminum Precision NC turned part

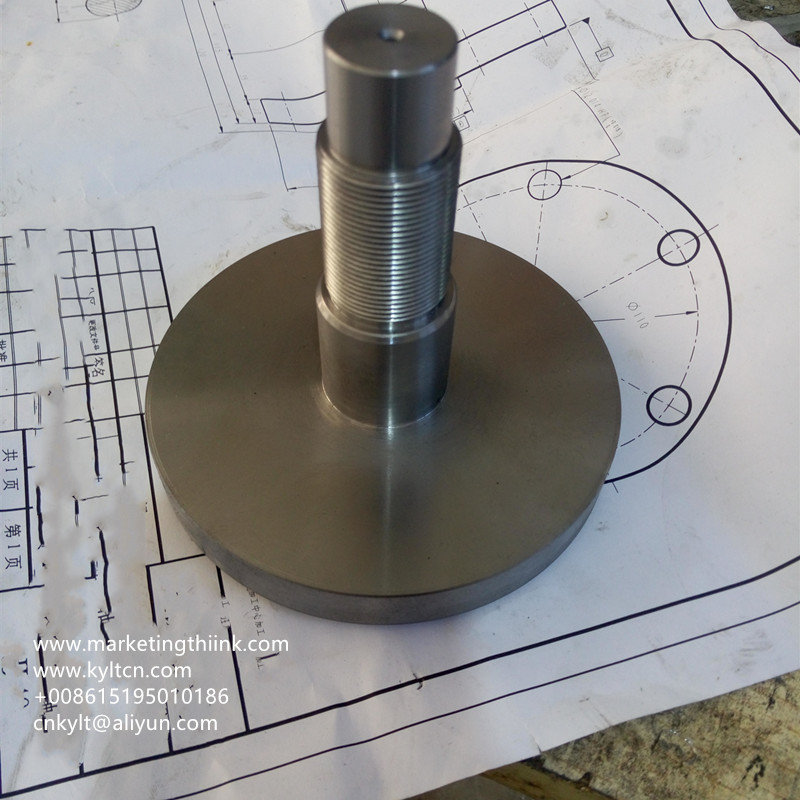

8.Steel NC turning part

9.Stainless steel NC turning part

10.Plastic material (POM) turning service

FINISHED SURFACE TREATMENT: PAINTING, POWDER COATING, ANODIZING, PLATING, POLISHING, SHOT BLASTING…

PLASTIC INJECTION MOLDING PRODUCTS

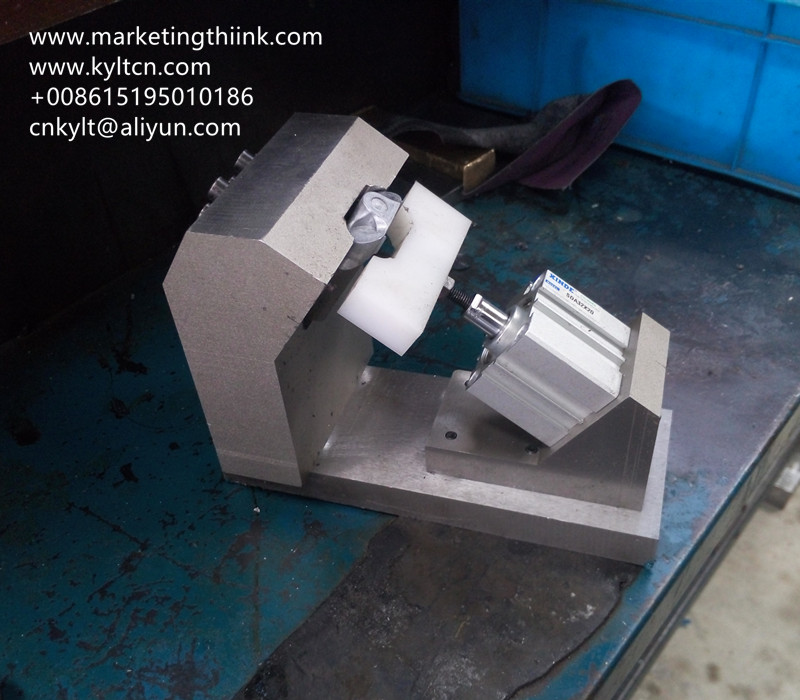

ASSEMBLY AS PER CUSTOMERS DEMAND AFTER MACHINING OR INJECTION

SHIPPING IN TIME BY VESSEL, AIR, EXPRESS(TNT, DHL, FEDEX, UPS, EMS…)

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论