Medical devices making such as operating forceps, they are by WEDM, EDM, CNC milling, Polishing etc, metal making and manufacturing processes. In fact, the medical devices making processes normally involve: metal making processes and plastic injection processes.

what is medical devices?

Medical devices are those equipment, instrumentation, equipment, calibration and other related similar items which used in the human body directly or indirectly.

The treatment of the human body is mainly obtained through physical methods, not through pharmacology, immunization, metabolic methods. The state has strict legal regulations on the manufacture and application of medical devices, so it has clear provisions on the design, safety, stability and effectiveness of medical devices. Medical device parts processing accuracy directly affects the safety and reliability of medical devices, the CNC precision machining applications to ensure the precision of processing parts.

What is KYLT medical device making services?

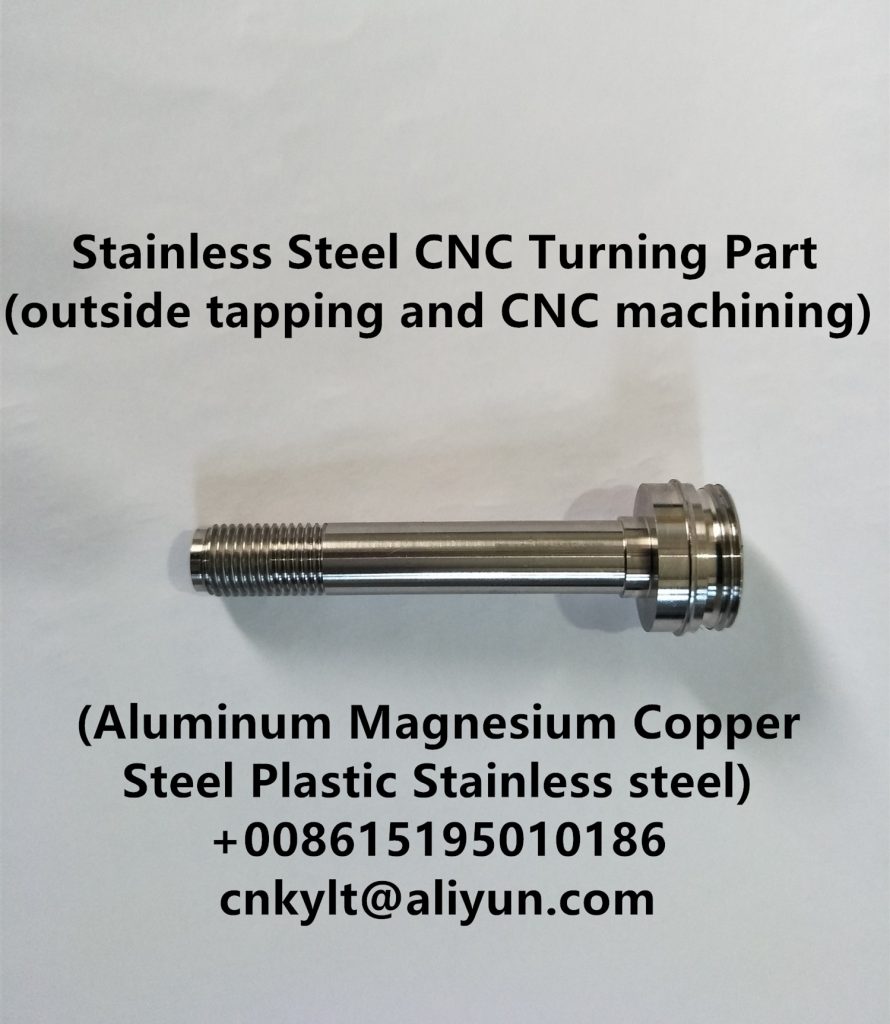

KYLT as the terminal medical devices spare parts producer,provide WEDM,EDM,Precision CNC, Lathing,Tapping machining service as per clients drawings.

Here is forceps part, which making processed by WEDM(Wire Cut Electro Discharge Machining) firstly,then use CNC precision machining to got the drawing requirement.

Medical devices materials which by CNC machined involve: iron, steel, stainless steel, aluminum,titanium alloy etc.

Any questions about medical devices spare parts machining and making, please feel free contact with KYLT:

www.marketingthiink.com

www.kyltcn.com

+008615195010186

cnkylt@aliyun.com

www.kyltcn.com

+008615195010186

cnkylt@aliyun.com

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论