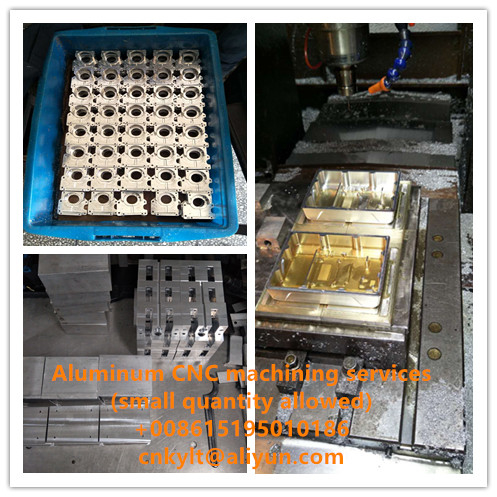

KYLT One-Stop CNC Machining Service Including Custom Finishing Service. On-demand manufacturing, Machining Metal &Plastic Parts Materials. FREE quotation. Parts In As Fast As 1 Day.

What is the Advantages of Choose KYLT CNC Machining services?

Ability to produce custom-made metal CNC machining parts, CNC machined part with high precision, delivery in time, CHEEP price, FREE quotation, MOQ 1PCS.

Over 10 kinds of plastic and metal machining.KYLT provide various types of CNC machining services no matter what your demands or requirements are. We can deliver parts in as fast as 24 hours.

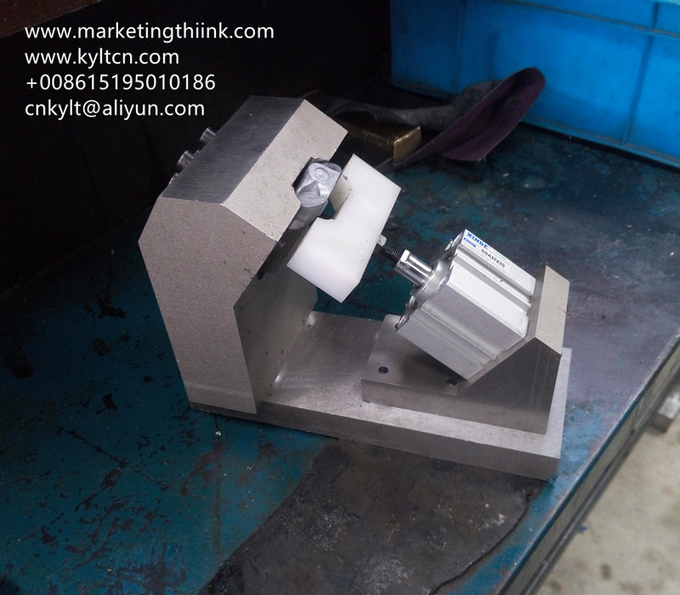

CNC machining service offering instant quotes on high precision custom parts. KYLT CNC manufacturing network provides machined prototypes and mass production. All kinds of plastic, metal Fixture (jig, tooling) making service.

CNC quote with FREE, custom parts delivered in time.Rapid CNC prototypes making and Precision CNC machining service that meets your most stringent requirements.

What is CNC used for?

CNC machining is a manufacturing Method in which pre-programmed computer software dictates the movement of factory tools and machinery. The Method can be used to control a range of Intricate machinery, from grinders and lathes to mills

and routers.

KYLT Highest Quality fixture making service, fixture for CNC drilling hole,Checking tool and assembling jigs.

KYLT One-Stop Service Include Rapid Tooling, Rapid Prototypes & Low Volume Production, Instant Online Response, Chinese workshop directly.

Free quotation, 40%-60% Lower Cost.

Rapid Tooling &Plastic Injection Molding Service Will Cater All Your Needs.

KYLT CNC Machining Service Including Custom Finishing Service. On-demand manufacturing, Machining Metal &Plastic Parts Materials.Parts In As Fast As 1 Day. Factory Price, Wide Range Of Products, Quality Assured, Effective Sourcing.

Get A Free Manual quotation, Instant Quote Online by Files: +008615195010186cnkylt@aliyun.com

High-Quality Rapid Prototypes making & Fixture, Jig making Service Will Cater All Your Needs.

What is CNC machining and how does it work?

CNC or computer numerical control?Appliance is a Large Accuracy Device that's

computer-controlled and makes repeated, Precise movements. It does so by taking

computer-generated code and converting it with software to electrical signals.

CNC machines can do almost Something you need them to do.

FREE QUOTATION

MOQ 1PCS

40-60% CHEAPER THAN OTHERS

www.marketingthiink.com

www.kyltcn.com

+008615195010186

cnkylt@aliyun.com

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论