KYLT precision CNC milling service.

CNC machining service offering instant quotes on high precision custom parts. KYLT CNC manufacturing network provides machined prototypes and mass production.

CNC machining service offering instant quotes on high precision custom parts. KYLT CNC manufacturing network provides machined prototypes and mass production.

KYLT provide various types of CNC machining services no matter what your demands or requirements are.

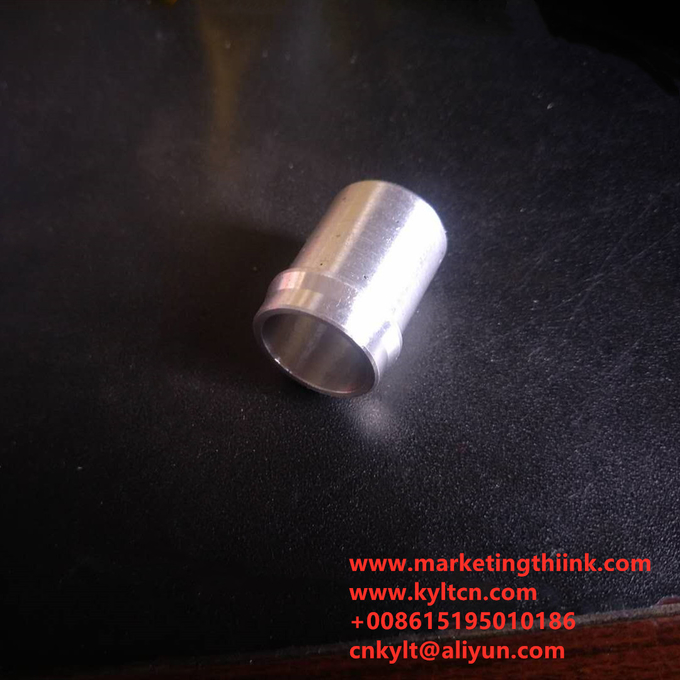

KYLT precision CNC turned aluminum bushing making service.

KYLT CNC Turned Part, Precision CNC Turned Component Manufacturer. Manufacturer of CNC Turned Part, Precision CNC Turned Component, CNC Turning Component, CNC Turned and CNC Precision Turning Service.

KYLT CNC Turned Part, Precision CNC Turned Component Manufacturer. Manufacturer of CNC Turned Part, Precision CNC Turned Component, CNC Turning Component, CNC Turned and CNC Precision Turning Service.

KYLT Precision milled aluminum quick prototypes by CNC machine

Customized machining centers & special machines for metal machining, Custom OEM Machining / CNC Lathe 3-4AXIS machining In China. With Quality Certificated, Complex parts, Fully equipped, Accurate delivery, Low price, Experienced engineer, Rich experience, MOQ 1PCS. Metal Parts Machining, Copper Parts Machining, Steel Parts Machining.

Customized machining centers & special machines for metal machining, Custom OEM Machining / CNC Lathe 3-4AXIS machining In China. With Quality Certificated, Complex parts, Fully equipped, Accurate delivery, Low price, Experienced engineer, Rich experience, MOQ 1PCS. Metal Parts Machining, Copper Parts Machining, Steel Parts Machining.

KYLT CNC Turned Parts are precision turned parts manufacturer based in China. Subcontract CNC turning services as per customers drawing or samples.

turning parts, CNC turning, lathe turning, Aluminum machining part, Steel machining parts, Copper machining small parts

Customized machining centers & special machines for metal machining, Custom OEM Machining / CNC Lathe 3-4AXIS machining In China. With Quality Certificated, Complex parts, Fully equipped, Accurate delivery, Low price, Experienced engineer, Rich experience, MOQ 1PCS.

Hot punched gear by CNC turning.

KYLT is a precision turning supplier for turned parts and OEM services. High quality Aluminum, Stainless steel, Steel iron, Copper, Plastic material NC turning part service.

- FREE QUOTATION

- MOQ 1PCS

- 40-60% CHEAPER THAN OTHERS

WHAT IS TURNING MACHINING?

Turning is a machining process in which a cutting tool, Usually a non-rotary tool bit,

describes a helix toolpath by Shifting more or Much less linearly while the workpiece rotates.

Usually the term "turning" is reserved for the generation of Exterior surfaces by this cutting

action, whereas this same Crucial cutting action when applied to internal surfaces (holes, of

one kind or another) is Known as "boring". So the phrase "turning and boring" categorizes the

larger Loved ones of processes known as lathing. The cutting of faces on the workpiece, No matter whether with a turning or boring tool, is Known as "facing", and may be lumped into either Class as a subArranged.

Turning can be Completed manually, in a traditional Type of lathe, which Regularly requires

Steady supervision by the operator, or by using an automated lathe which does not. Today the

most common type of such automation is PC numerical control, better known as CNC. (CNC is

also commonly used with many other types of machining besides turning.)

When turning, the workpiece (a piece of relatively rigid Substance such as Wooden, Material, plastic,

or stone) is rotated and a cutting tool is traversed along 1, 2, or 3 axes of motion to produce precise diameters and depths. Turning can be either on the outside of the cylinder or on the Within (also known as boring) to produce tubular components to various geometries. Despite the fact that now quite Unusual, early lathes could even be used to produce complex geometric figures, even the platonic solids; although Given that the advent of CNC it has become unusual to use non-Pcized

toolpath control for this purpose.

The turning processes are Usually carried out on a lathe, Regarded to be the oldest of

machine tools, and can be of Distinct types such as straight turning, taper turning, profiling

or Exterior grooving. Those types of turning processes can produce various shapes of Substances

such as straight, conical, curved, or grooved workpieces. In general, turning uses Very simple One-

point cutting tools. Each group of workpiece Substances has an optimum Arranged of tool angles that

have been Produced through the Many years.

The bits of waste Material from turning Functions are known as chips (North America), or swarf

(Britain). In some Places they may be known as turnings.

The tool's axes of Motion may be literally a straight line, or they may be along some Arranged of

curves or angles, but they are Crucially linear (in the non mathematical sense).

A component that is subject to turning Functions can be termed as a “Turned Part” or

“Machined Component”. Turning Functions are carried out on a lathe machine which can be

manually or CNC operated.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

评论

发表评论