Stainless steel rapaid prototype is widely used in Medical usage parts and devices. As one of the common materials for rapid prototyping and prototype manufacturing, KYLT provide quality parts, MOQ 1pcs is allowed.

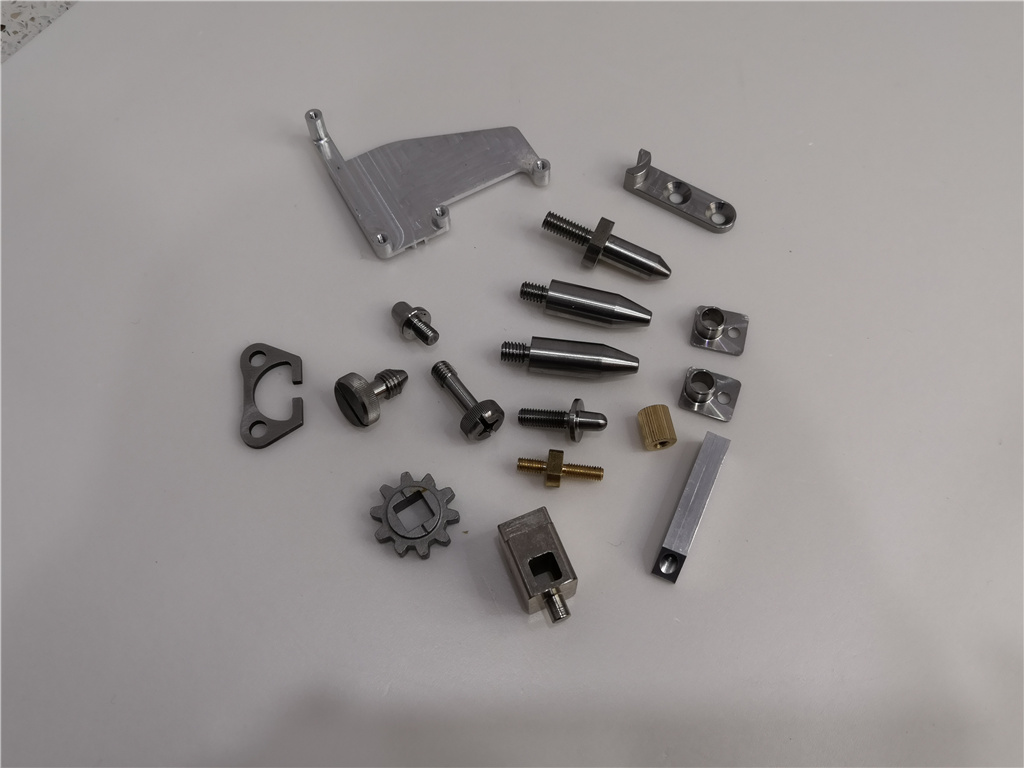

Today, we will show one stainless steel rapid prototype, which made by CNC milling.

Stainless steel rapid protype structure description:

- Cylinder body dia. 12mm, length 25mm

- one end with ovel-shaped flange. Dia. 2mm assembly holes for screws. Flange thickness:2mm

- Flange side bottom has a rectangle structure hole (not through). Rectangle length 10mm, Width 8mm, depth 25mm

STAINLESS STEEL RAPID PROTOTYPE MACHINING PROCESS:

- Stainless block cutting as per demand

- Precision turning machine by NC lathe to got cylinder structure

- CNC milling to finish the flange structure and holes with chamber

- CNC milling, the rectangle structure be finished

MORE DETAILS OF THIS STAINLESS STEEL RAPID PROTOTYPE VIDEO:

structure description: KYLT provide high quality stainless steel CNC machining prototype from 1 off prototype to 100 low volume production run.

Samples or Pieces stainless steel prototype can be done precisely by CNC machining. As Stainless steel is much harder than aluminum alloy, that costs about 2 to 3 times longer hours to machine than aluminum. In China, 303, 304, 316, 316L, 17-4PH, 416, 420 stainless steel are available for CNC machining.

Normally we will keep the milled and turned parts as machined finish if there’s no specific surface finish required.

Ra0.8 surface roughness can be achieved by CNC machining.

Quality machined surface and dimensional accuracy be insured by CNC machines and cutting tools.

More KYLT Machining Services & Products Information:

Visit CNC Milling Parts, EDM/WEDM Parts , CNC Machining Service, Rapid Prototype for your reference.

To get more information about KYLT products and services, please e-mail to cnkylt@aliyun.com to get a FREE quote.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology:

评论

发表评论