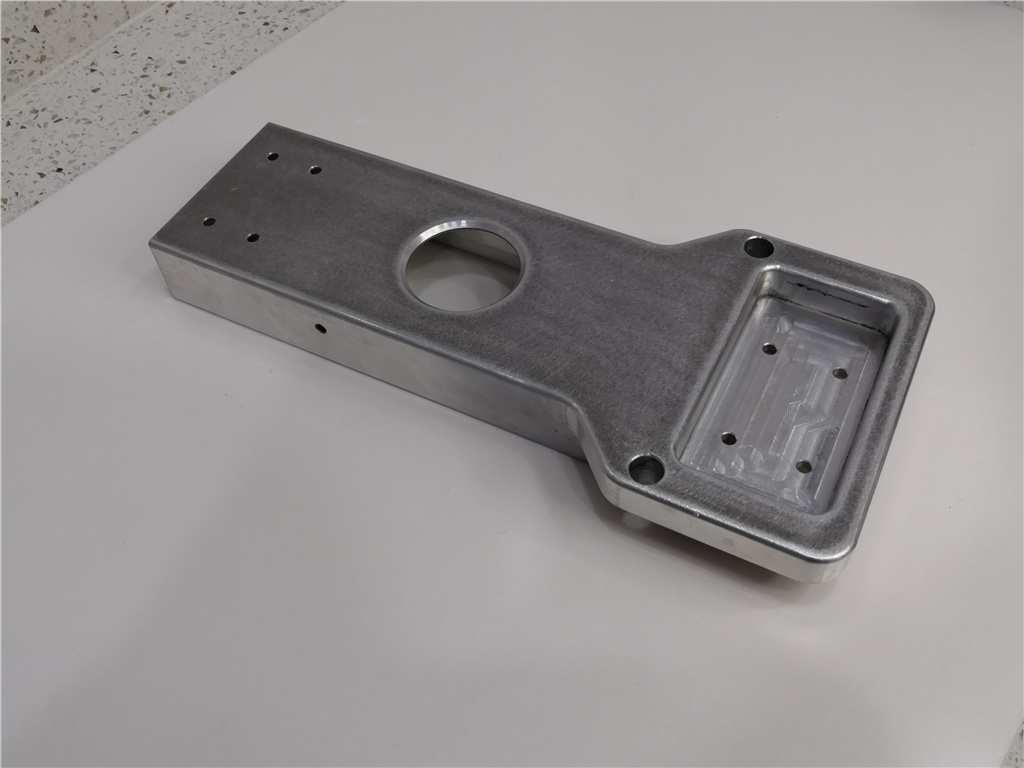

Aluminum rapid prototyping (also named: aluminum prototyping, fast prototyping, quick prototyping). Rapid prototyping is a quick method to got a finished part from design, then to check and test the desingned part function.

Aluminum alloy is a reasonable material and widely used in industry.

With the developing on aluminum alloy materials, high-strength aluminum alloy with its excellent comprehensive performance in the use of commercial aircraft has reached its structural quality of more than 80%, so get the global aviation industry generally attention. Aluminum began to gradually applied to life, military, science and technology.

ALUMINUM ALLOY FUNCTIONS:

- low in density but high in strength

- close to or superior to high quality steel

- good plasticity

- excellent process ability

- excellent welding characteristics and electroplating

- good corrosion resistance

- high toughness and deformation after manufacturing

- defects and easily polished

- easy to color film

- excellent anodizing finished and other excellent features(painting, powder coating, plating etc)

Over ten years experience with aluminum prototype machining, Our CNC engineer experienced in complex structure part machining and skill to manufacture quality aluminium prototype parts. From One prototype to Mass production, We will quote and reply with 24hr.

ALUMINUM RAPID PROTOTYPING:

MORE KYLT STAINLESS PART MACHINING SERVICES & PRODUCTS INFORMATION:

Visit CNC Milling Parts, EDM/WEDM Parts , CNC Machining Service, Rapid Prototype for your reference.

To get more information about KYLT products and services, please e-mail to cnkylt@aliyun.com to get a FREE quote.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology:

评论

发表评论