LZ13000KN Cold Chamber Die Casting Machine, High Pressure Die casting machine, Horizontal type with PLC control. Working with auto ladling machine, Sprayer, Pick-up machine to reach full automatic die cast. Email: cnkylt@aliyun.com

DC1300T Horizontal Cold Chamber Die Casting Machine Specification (LZ1300T)

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. )

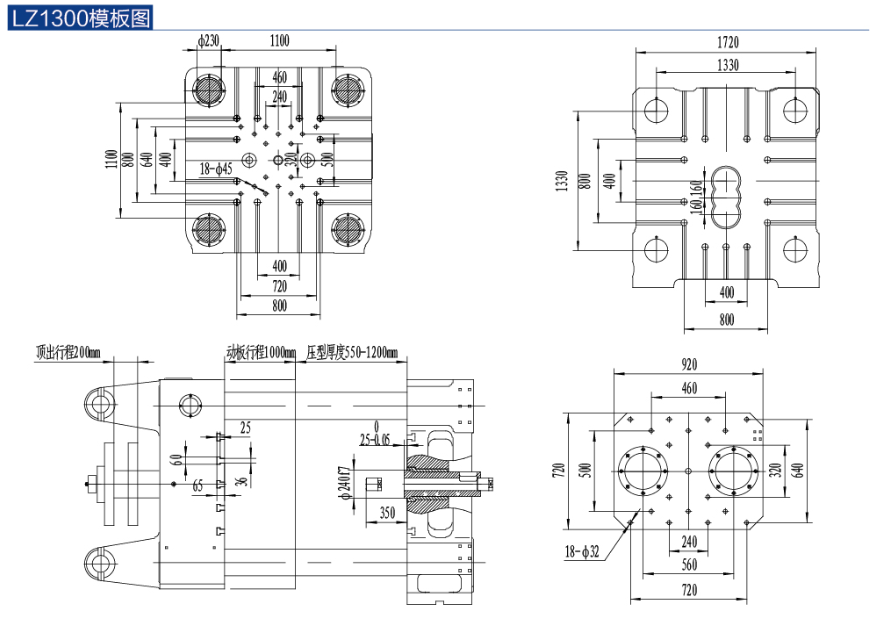

LZ 1300 Ton Die Casting Machine Molding Plate Specification:

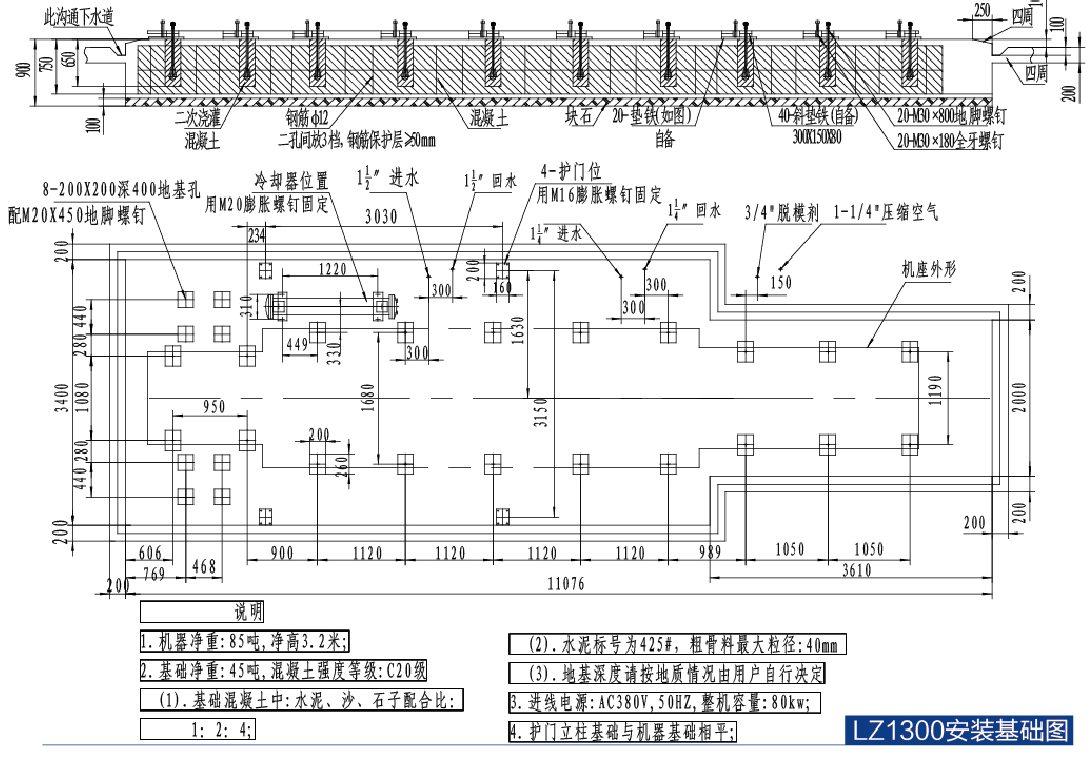

LZ 1300 Ton Die Casting Machine Cement Ground Specification:

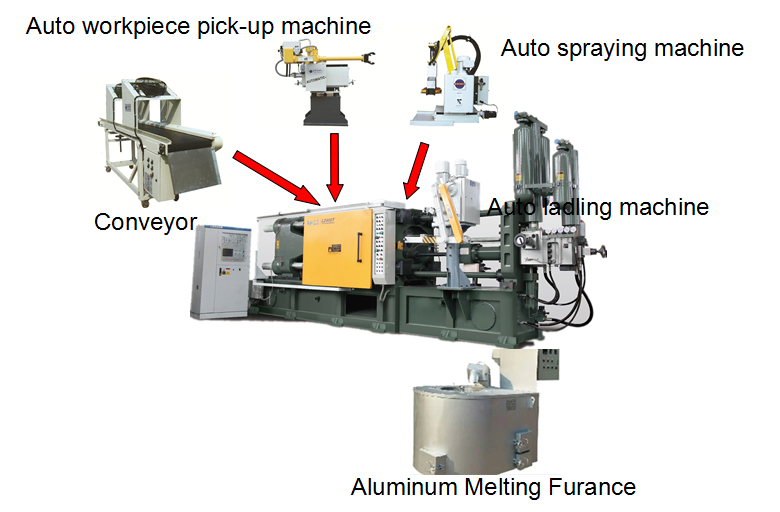

Heavy Duty Horizontal Cold Chamber Die Casting Machine Working Process:

Heavy Duty Horizontal Cold Chamber High Pressure Die Casting Machine which need ladle heavy weight alloy from melting pot to machine cold chamber. So, whole die casting process must use automatic machines or robots to reach full automatic running.

Full Automation horizontal cold chamber die-casting machines:

Automation equipment makes the die casting process full automatically.

The whole automatic die casting unit involve:Melting furance, Auto lading robot, Die casting machine, Auto sprayer, Die casting parts pick-up machine (Extractor).

What is the Automatic Cold chamber die casting machine process?

Full automatic die casting working process: Die casting machine PLC control the whole process. Automatic ladler pour molten aluminum metal alloy from melting pot to die casting machine cold chamber. Then, be inject to mold cavities to got die-cast parts. Auto extractor pick-up casting part from die tool, put them on conveyor. The auto sprayer cooling and lubricating the mold cavity. And, to start then next die casting process.

Key Elements Brands of LZ high pressure cold chamber die casting aluminum molding machine:

(Remark: Aluminum Molding Machine Spare parts brands can be changed as per customer demand. The producer of die casting machine-LZ (China) keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then. Die Casting Machine spare parts brands can be changed as per customer demand.)

Die Casting Machine Before and After Sales Services:

Before Sales Services

Provide pre-sales consultation such as investment budget and plant planning, so as to make the customer's plant design reasonable, standardized and save costs.

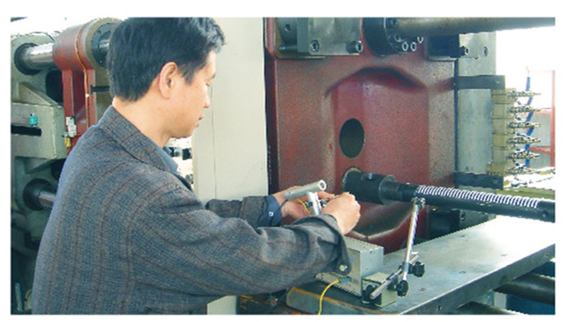

Exworks test

Continuous grounding resistance test

Injection speed test

Clamping force test

Electric control system test

Machine appearance inspection

Full load test for more than 72 hours

After Sales Services

By guiding customers to install the water and electricity of die casting machines, adjusting new machines. Training customers' technicians and operators. The machine placement is standardized and reasonable. Enable relevant personnel to be familiar with the machine operation and maintance.

Provide FREE standard spare parts together with machine.

Install die casting machine.

Trainning Die casting operator.

Any questions be replied by email, video, photos within 24hr.

Engineer guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

More information about our 1300T Heavy Duty Die Casting Machine Service, Please email us: cnkylt@aliyun.com.

评论

发表评论