550T Cold Chamber Die-cast Machine used to make middle size die casting parts. Such as washing machine pully, Washing machine Drum Spider/Bracket/Support/Holder etc Aluminum, Zinc parts. Manual and Automatic Operations also allowed. Email: cnkylt@aliyun.com

DC550T Cold Chamber Die-cast Machine Specification (LZ550T)

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

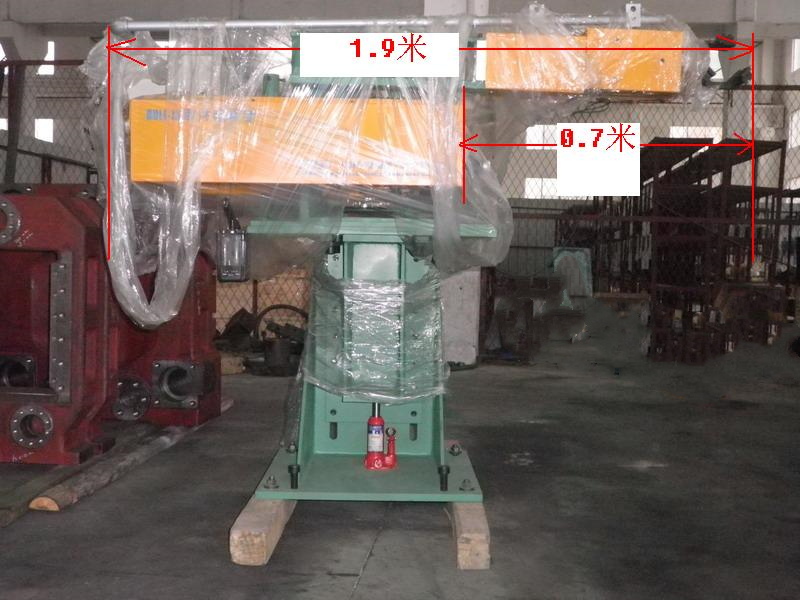

(Photo shows our 550T machine. OEM as per Yeman client demand.)

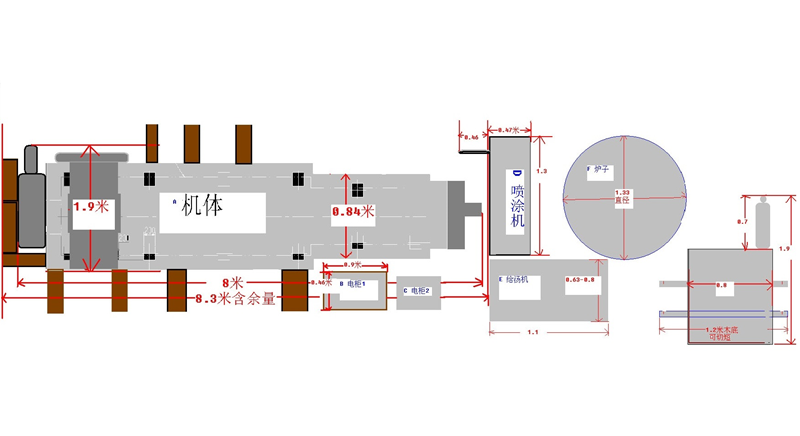

In this project, customer requires automatic die casting process. Automatic ladling machine, Auto Spraying machine, Auto die cast parts pick-up machine and melting furnace should be shipped together with machine.

OEM 550T Aluminum die casting machine

2. Aluminum melting furnace

3. Automatic ladling machine & Spraying Machine

4. Die casting parts pick-up machine

Technical information and prices of Automatic ladling machine, Auto Spraying machine, Auto die cast parts pick-up machine and melting furnace, Please email: cnkylt@aliyun.com

Full automatic aluminum cold chamber die casting unit working process video:

Youtube: https://youtu.be/npYbgva3NK8

Full automatic working process:

Die casting machine PLC control the whole process. Automatic ladler pour molten aluminum metal alloy from melting pot to die casting machine cold chamber. Then, be inject to mold cavities to got die-cast parts. Auto extractor pick-up casting part from die tool, put them on conveyor. The auto sprayer cooling and lubricating the mold cavity. And, to start then next die casting process.

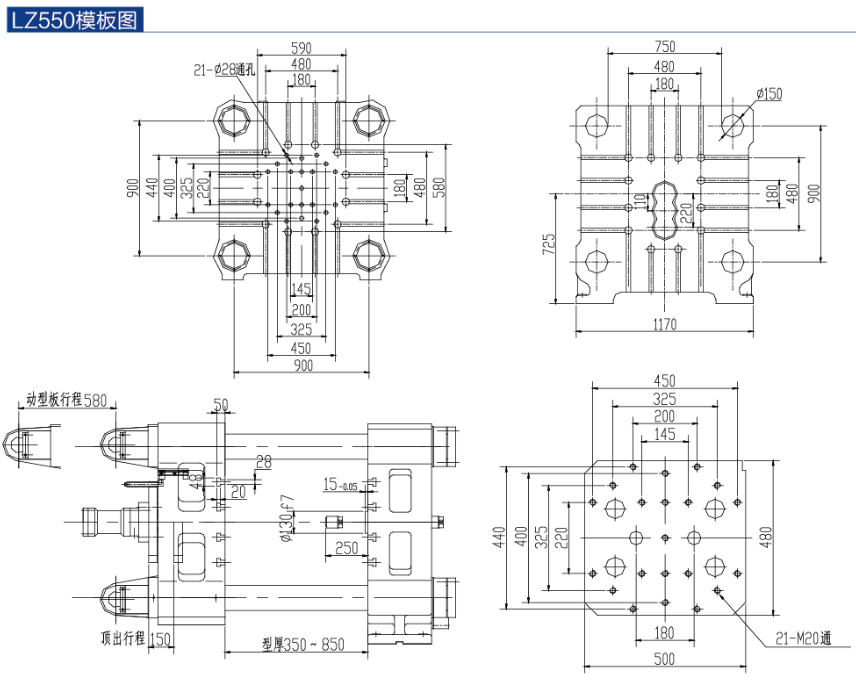

LZ 550T Cold Chamber Die-cast Machine Molding Plate Specification:

LZ 550T Cold Chamber Die-cast Machine Molding Plate Specification:

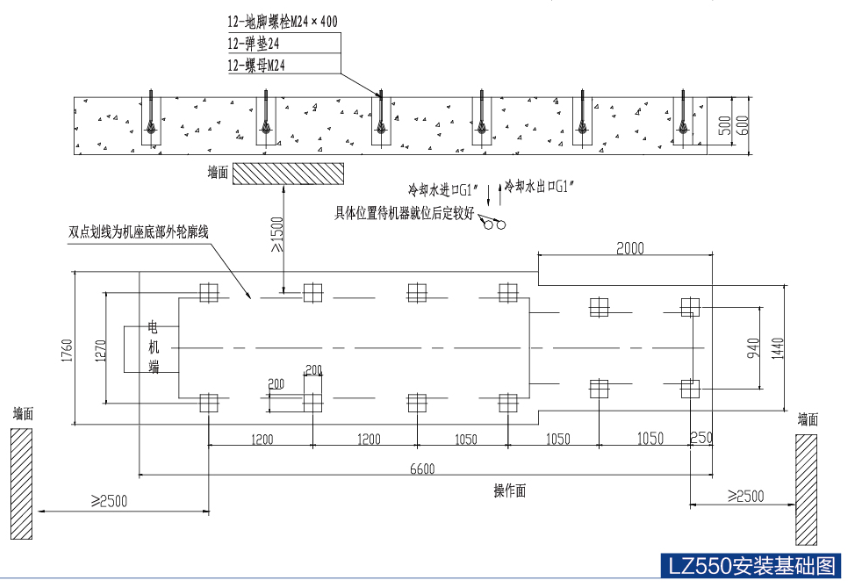

Shipping and Delivery of Automatic cold chamber die casting unit:

All machines be loaded in 40' OPEN TOP CONTAINER. From Shanghai port To Yemen by SEA.

Loading Plan

We need to know container inner sizes, and arrange every machine position as per their shapes and dimensions.

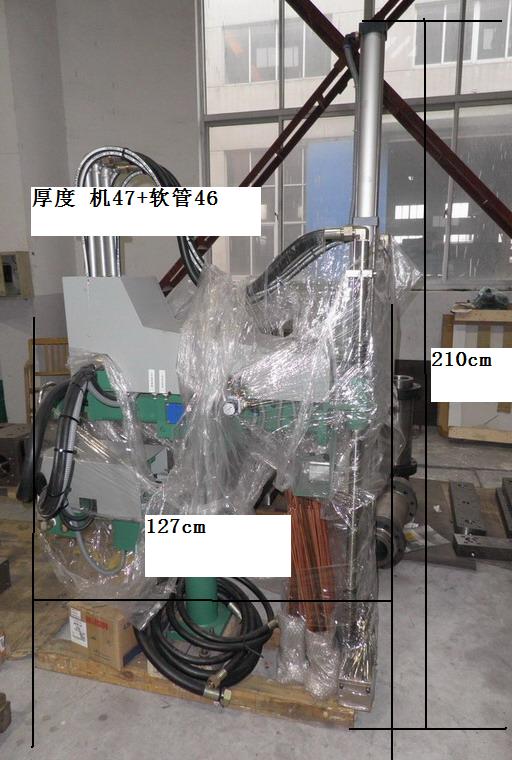

Disassembly and Safe packing

As some structures are too high over the hight of container roof, we need to disassemble them. Use soft materials to pack machines corners and fragile products.

Auto ladling machine be packed

Auto die cast parts pick-up machine be packed

Auto spraying machine be packed

Packed aluminum melting furnace

Free spare parts be packed

Hoisting

All machines designed with hoisting positions, that is easy for load machines to container.

Short Youtube Video of Die casting machine be load into container:

Short Youtube Video of Die casting auxiliary machines be load into container:

More information about 550T Cold Chamber Die-cast Machine cost and Service, Please email us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论