Over 35 years experience of the die casting machine design and manufacturing.

As one Cold Chamber Die Casting Machines manufacturer, LZ brand has over 35 years experience of the die casting machine design and manufacturing.

With good quality and stable function, LZ die casting machinery service for over 3 hunders small and medium-sized die casting companies and suppliers in china, and export to Egypt, Yemen, India, Vitenam, Algeria etc countires.

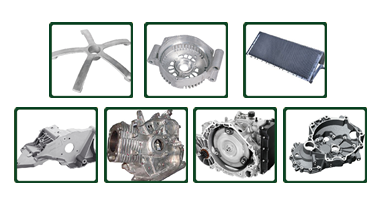

We experience on provide "ONE-STOP" service and solution for your die casting projects. The materials are widely used in manufacturing Aluminum, Magnesium, Zinc, Copper alloy die casting parts.

How to classify the type of Horizontal Cold Chamber Die Casting Machine?

Cold Chamber Pressure Die Casting Machine tonnages are different from 160T, 200T, 280T, 350T, 550T to 1100T.

According materials types of die casting, the cold chamber die pressure casting machines can be calssified:

Aluminum Die Casting Machine, Magniesium Die Casting Machine, Zinc/ZAMAK Die Casting Machine, Copper/Brass Die Casting Machine.

As per automatic grade, the die casting machinery can be classified: Manual Die Casting Machine, Automatic Die Casting Machine.

As per injection method, the metal castingmachine can be named: Plunger Cold Chamber Die Casting Machine, High Pressure Casting Chamber Machine

LZ Die Cast Machine quality waranty and services:

12 months after machine put into operation. If the die cast equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

LZ "ONE-STOP" die casting solution:

die casting factory design

casting machines assembly and adjustment

die cast molds & tools making

finished casting parts

LZ High Pressure Die Casting Machines Useage and Characteristic:

LZ High Pressure Casting Machines are widely used in industrial lines of Aviation, Automobile, Motorcycle, Telecom instrument, Electrical home appliances hardware. And they are used to produce large Aluminum, Magniesium, Zinc, Copper and other non-ferrous metal casing parts.

LZ Cold Chamber Die Cast Machine advantages:

High performance:

The max. dry inject speed over 7m/s, and pressurization & creation duration more fast.

High reliability:

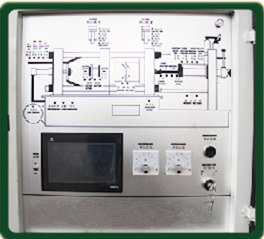

Metal Die Casting Machine adopts PLC programmable controller. And control the transmission by the hydraulic pressure drove. (That is reason,why the casting machine also named: Hydraulic die casting machine, PDC - Pressure Die Casting Machine .) Diecast machinery is designed & produced as per excellent quality structure. They are reliability and durability.

High-speed die-casting production:

Die locking force and injection force adopts the proportion of conditioning systems. Which keep the machines always in the rational work state. So these machines realize high-speed production.

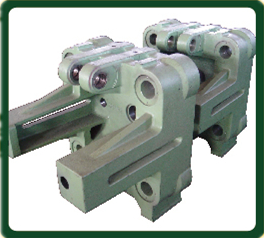

Stable clamping system:

The clamping parts are made of high-strength nodular cast iron and inclined row structure. Finite element analysis used to check the clamping system. The pressure distribution is reasonable. That ensure the long-term stability of the machine accuracy, not easy to deform. Significantly reduce the impact of opening and closing mold, and prolong the machine life.

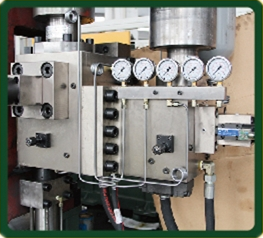

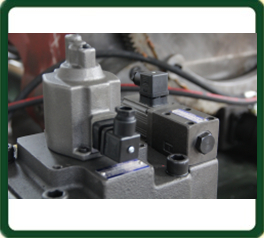

Sensitive hydraulic system:

The hydraulic system adopts proportional control system. The parameters setting is convenient. The die casting mechanism operation is fast, stable, safe and reliable.

Fast injection system:

The injection system adopts independent accumulator. The fast injection & pressurization adopts newly developed fast reaction throttle valve. Which greatly improves the acceleration performance of fast injection. Shorten the switching time of high-speed and pressurization. It is an important symbol of the superior injection performance of modern high-quality die casting machine.

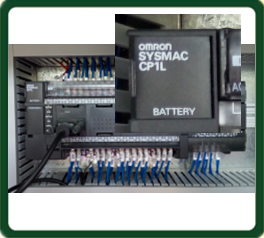

Famous brands PLC control system:

The electrical system: Mitsubishi PLC, OMRON PLC and Schneider electric components.

Touch screen used to adjust and set the parameters.

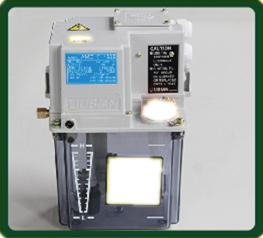

Quality lubrication system:

The lubrication system of die casting machine parts adopt self inspection connector. If the oil circuit is blocked at any point that can be quickly detected. The undervoltage protection system can prevent the elbow parts from serious wear and even fracture due to lack of oil, and prolong the service life of the casting equipment.

LZ series cold chamber die casting machine technical specifications

1. LZ150~268T Main specifications and parameters.

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

2. LZ300~550T Main specifications and parameters.

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

3.LZ700~1300T Main specifications and parameters.

(Remark:The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then.)

4.Cold Chamber Die Casting Machine Catalog & Brochure download:

PDF TYPE:

LZ150~LZ2000

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdfJPG TYPE:

LZ150~LZ550

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpgLZ700~LZ2000

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpgMore die casting machine catalog, images, photos or die casting videos, pls. email us: cnkylt@aliyun.com

The information of die casting machine for sale and die casting machine price, pls. email us: cnkylt@aliyun.com

5.Key Elements Brands of die casting machine:

(Remark: Spare parts brands can be changed as per customer demand. The company keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. Spare parts brands can be changed as per customer demand.)

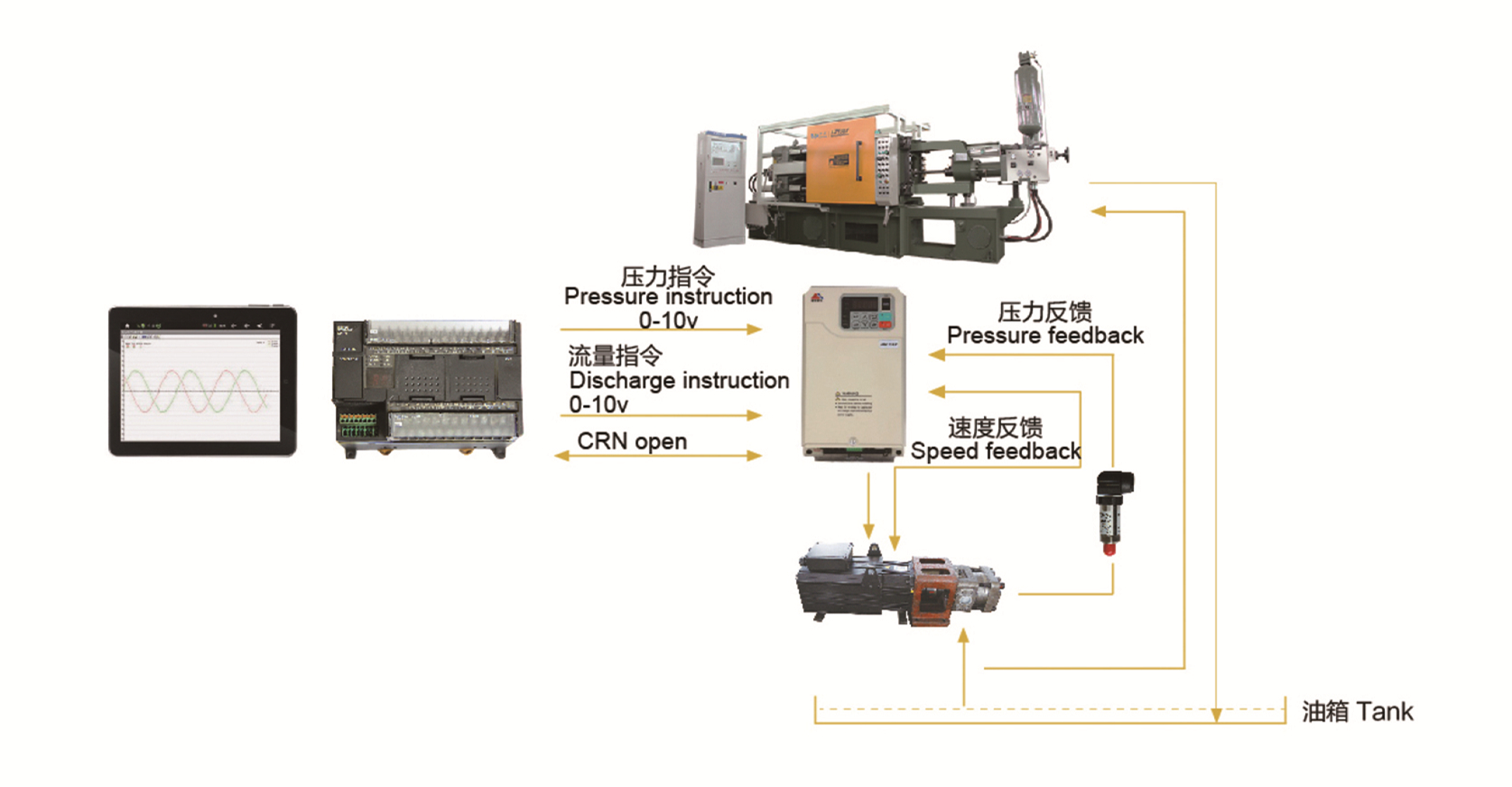

Servo Drive Cold Chamber Die Casting Machine

Servo Motor used to drive the die casting machine and conserve energy, which help die casting factory to save money. It is the key character of servo pressue die casting machine.

The Servo dirven cold chamber die casting machine extra working process consists: Pressure instruction unit, Pressure feed back unit, Discharge instruction unit, CRN open, Speed feedback unit,

Cold Chamber Die Casting Machine Services and Warranty:

1.Pre-sale Service

By providing customers with pre-sales services of investment budget, plant planning and other forms, customers' planningis reasonable, standardized and cost saving.

Investment budget die casting machine selection and auxiliary equipment matching and budget

Plant planning: provide installation size of equipment foundation, equipment layout, workshop ventilation, exhaust, watertransportation, wiring, lifting equipment design services.

Provide information of various casting auxiliary equipment.

2.After-sale Service

Provide FREE standard spare parts together with machine.

Arrange engineers to your factory to install and adjust machines. Traning the worker to operate the machine.

Any questions be replied by email, video, photos within 24hr.

Our engineer can guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

(Photo shows LZ 1100 cold chamber pressure casting machine with after sale service: assembly and running test.)

3.Used die casting machines

Used cold chamber die casting machines repairment (About used aluminum die casting machine price & cost for maintain, please contact with: cnkylt@aliyun.com )

Old high pressure die casting equipment improvement

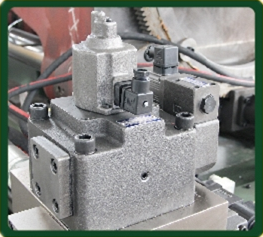

(Used Toshiba die casting machine have a complete overhaul in our factory. Photo show the injection molding structure of a used Toshiba aluminum die caster. )

More information about Cold Chamber Die Casting Machine and Mould Service, Please email us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论