Lead/PB Alloy Die Casting Machine types cold chamber, hot chamber horizontal & vertical machine. Small tonnage cold chamber used to produce big lead alloy parts, Horizontal Hot chamber machine can produce lead/Pb weight part, lead acid battery terminal or bushing, lead sealant etc. Vertical machine to produce fishing sinker/hook/bait/Luya etc. Email: cnkylt@aliyun.com

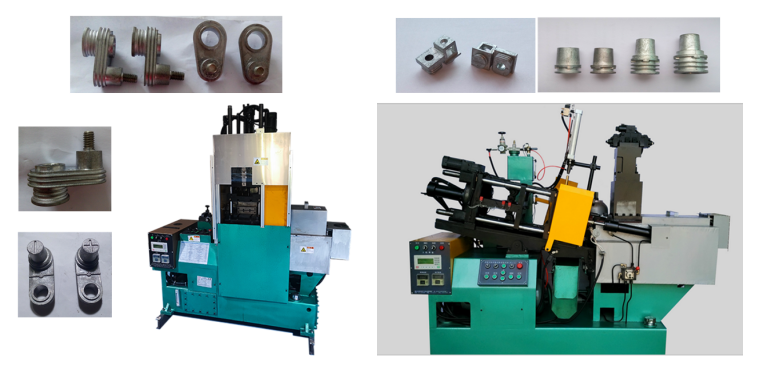

Lead PB alloy Die Casting Machine use to produce Pb alloy parts for machinery, fishing tackle, lead acid battery, Wheel balance weight etc.

Lead PB metal alloy die casting machinery inject liquid lead alloy to die casting die with high pressure. With this character, this casting machinery also named: high pressure lead injection machine, lead alloy pressure die casting machine, pressure lead injection machine etc.

Types of Lead PB die casting machine:

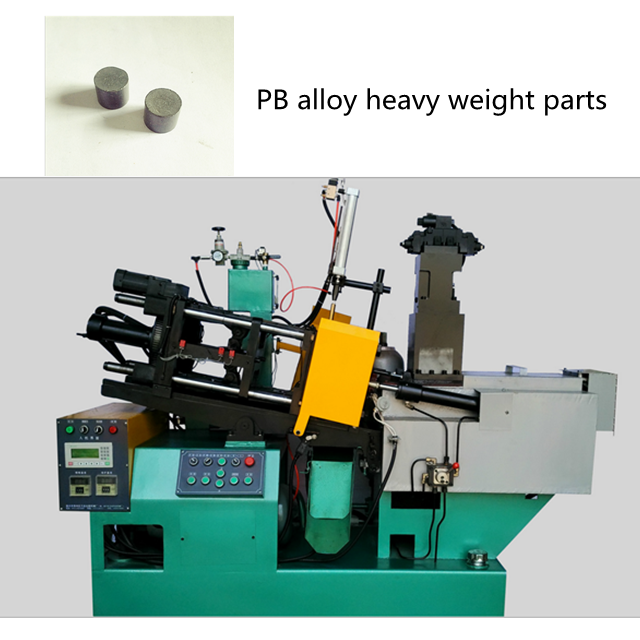

Lead heavy parts for machinery, which as weight parts to keep machine stable. Use cold chamber die casting machine 150T, 200T.

Small PB weight part, wheel balance weight use 20T Horizontal lead die casting machine.

Fishing sinker, fishing bait, fishing hook, fishing Luya use 20T Vertical lead die casting machine.

Lead acid battery terminal, bushing, connector etc parts also be cast by our 20T horizontal or vertical machine. Differnt battery terminal or bushing structure choose different machine type.

What is lead PB alloy die casting?

Lead alloy die casting process is forcing molten lead alloy through die casting machine cold chamber or hot chamber into pressure die/mould cavities to produce Lead PB die casting parts.

Lead die casting process involves 3key parts: lead alloy die casting machine, PB metal alloy melting furnace, lead die casting mould (lead PB pressure die).

More information about Lead PB alloy die casting machine, fishing metal parts making machine, lead acid battery terminal bushing machine Prices and Service, Please email us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论