- 1600KN

- LZ

- 8454301000

DC160 Ton Cold Chamber Die Casting Machine Specification (LZ160T)

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

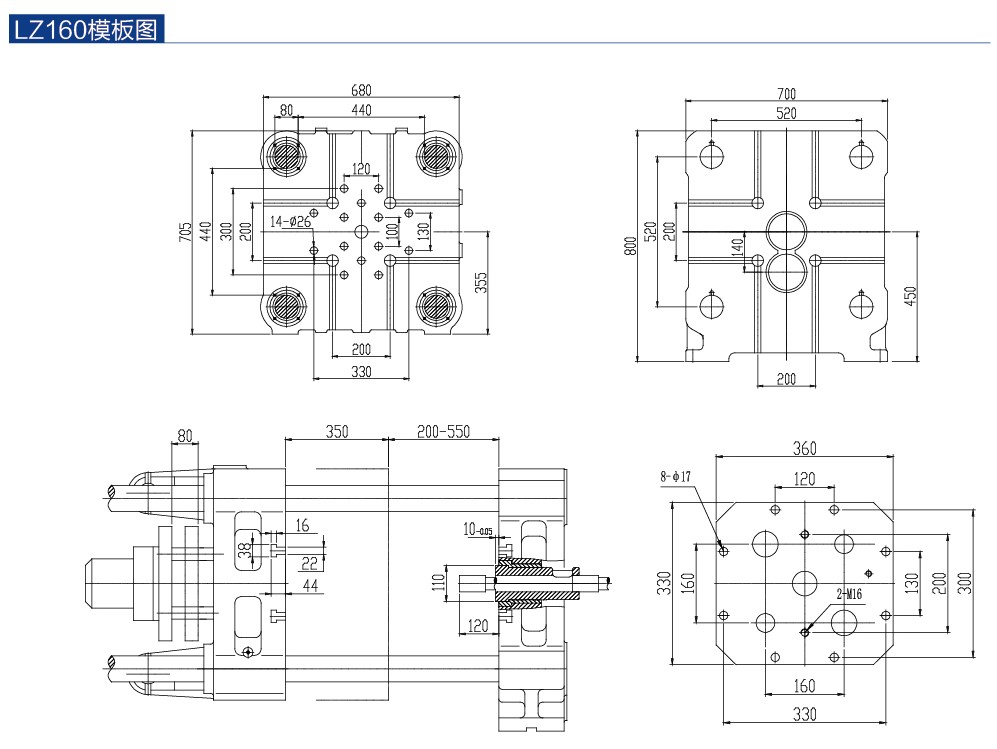

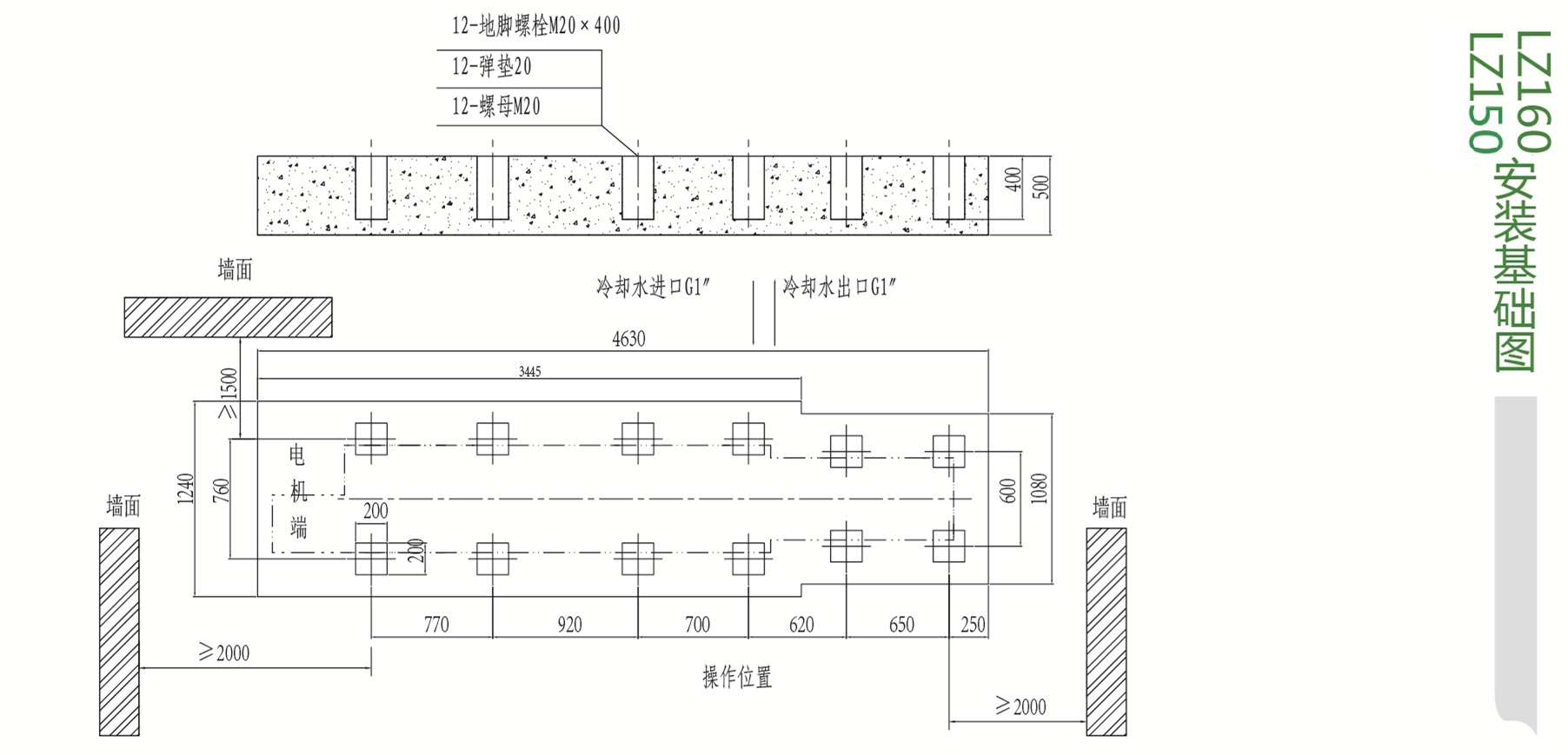

LZ 160 Ton Die Casting Machine Molding Plate Diagram:

HOW DOES A COLD CHAMBER DIE CAST MACHINE WORK?

Horizontal Cold Chamber High Pressure Die Cast Machine has two working methods: Maunual Operation and Full Auto Operation:

Manual high pressure cold chamber die cast machinery:

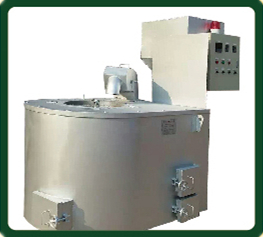

The manual operation involve two key machines: Horizontal cold chamber die-cast machine and Melting furance.

-Horizontal high pressure die caster can be choose standard type or servo driven type.

-Melting furance: Electric melting furnace, Gas melting furance, Biological particales melting furance.

(For magnesium alloy die casting, special Magnesium alloy automatic pouring melting furance must be used.)

Die casting machine melting pot types:

Graphite crucible for die casting machine melting kettle, it is popular in die casting process now.

Cast iron crucibe for pressure die-cast machine melting pot.

What is the Cold chamber die casting machine process

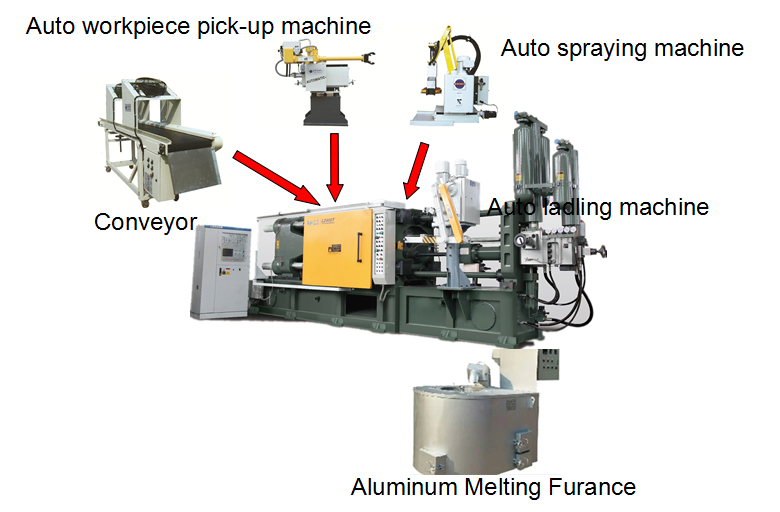

Full Automation horizontal cold chamber die-casting machines:

Automation equipment makes the die casting process full automatically.

The whole automatic die casting unit involve:Melting furance, Auto lading robot, Die casting machine, Auto sprayer, Extractor.

What is the Cold chamber die casting machine process?

In manual working process: die casting opeartor pour molten aluminum alloy from furance to cold chamber, then casting machine inject metal to die tool to get the die casting parts.

In full automatic working process: Die casting machine PLC control the whole process. Automatic ladler pour molten aluminum metal alloy from melting pot to die casting machine cold chamber. Then, be inject to mold cavities to got die-cast parts. Auto extractor pick-up casting part from die tool, put them on conveyor. The auto sprayer cooling and lubricating the mold cavity. And, to start then next die casting process.

How to choose suitable cold chamber die casting machine?

1.As per different die casting metal alloy, die caster types: aluminum die casting machine, zinc (zamak) die casting machine, magneisum die casting machine, copper (brass) die casting machine.

- Aluminum die casting machine used to produce aluminum alloy die casting parts. Use a gas or electric melting furance can start the production. Die casting mould normally is H13 mold steel.

- Zinc/Zamak die casting machine, in cold chamber types, it used to produce big zinc alloy die casting parts. (For small die casting parts, such as zipper slider, jewelry, electronic part, hot chamber die casting machine is more suitable.) Same as Aluminum die casting, just has an extra melting pot can start produce zamak die casting parts.

- Magnesium die casting machine. Magnesium alloy characters strong, light weight, easy for machining. It is more popular those years. To produce magnesium die casting part, specail ordered magnesium die casting machine with a magneisum alloy melting furance must be used. The furance connect with protect gas, avoid buring in melting process, quantitative feeding magnesium alloy to pressure machine cold chamber.

2. As per die casting machine tonnage, it can be classifed as: small die casting machine, large scale die casting mahcine.

Small die casting machine most is hot chamber high pressure injection machine. It has horizontal type and vertical type.

Large scale die casting machine normally is cold chamber pressure die-cast machine. Most is horizontal type.

Cold Chamber Die Caster specifications and parameters download:

PDF TYPE:

LZ150~LZ2000

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdf

LZ150LZ2000 cold chabmer die casting machine specifications and parameters.pdfJPG TYPE:

LZ150~LZ550

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpg

LZ150LZ550 cold chabmer die casting machine specifications and parameters.jpgLZ700~LZ2000

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

LZ700LZ2000 cold chabmer die casting machine specifications and parameters.jpg

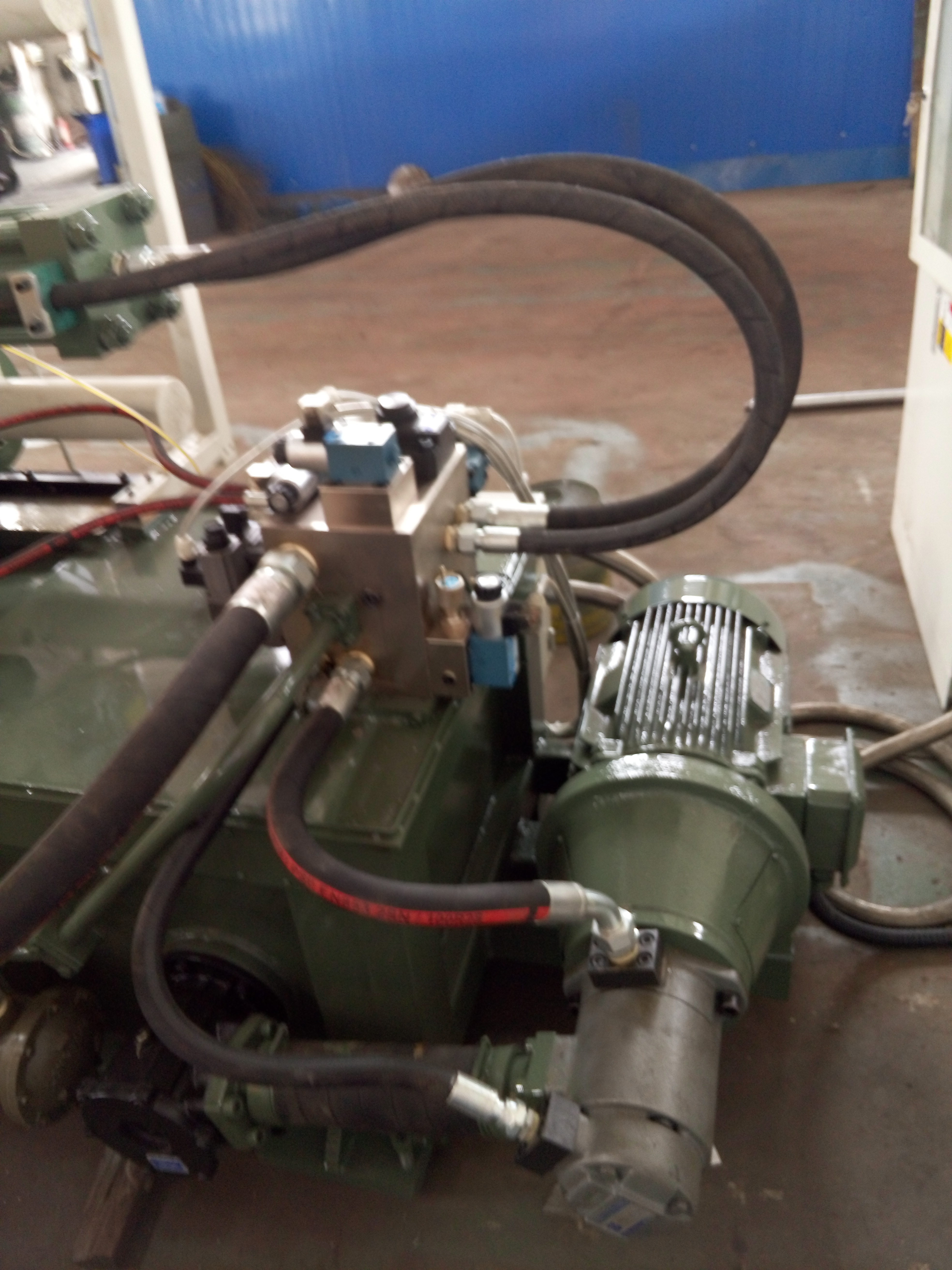

Key Elements Brands of LZ high pressure die casting aluminum molding machine:

(Remark: Aluminum Molding Machine Spare parts brands can be changed as per customer demand. The producer of die casting machine-LZ (China) keeps the right to revise above parameters. If there is any alterations, advance notice won't be given then. Die Casting Machine spare parts brands can be changed as per customer demand.)

High Pressure Die-Cast Machine performance characteristics:

DDC system and fast accumulation system, which shorten production cycle efficiently.

Central electrical lubrication system.

Hydraulic driven gear-type mould height adjusting mechanism.

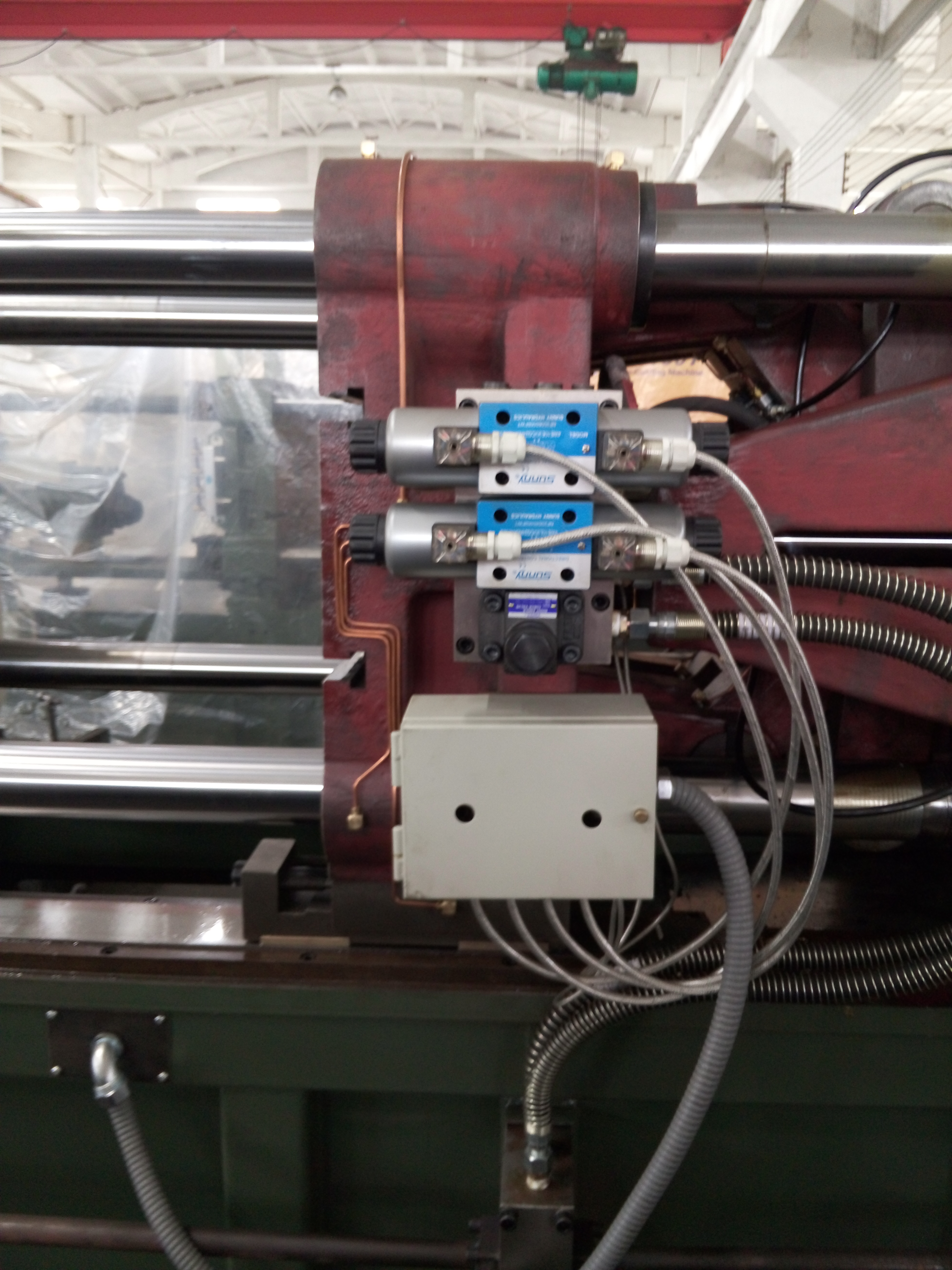

Four stages control of injection speed and pressure, independent high-speeding intensification injection accumulators. Quality accumulator in die casting machine insure the pressure output stable, strong, fast. Two intensification activation ways: position way and pressure way.

High rigidity molding platen, high tensile alloy steel hard chrome plated tie bar.

PLC control system (with touch screen) with fast, stable, safe and reliable operation, high precision, and functions such as production management, trouble diagnosis, and 50 sets mould parameters storage.

High speed hydraulic ejection and core-pulling devices.

Electrical proportional control of system pressure and flow, with multi-stage pressure and speed control, and low-pressure die close protection function.

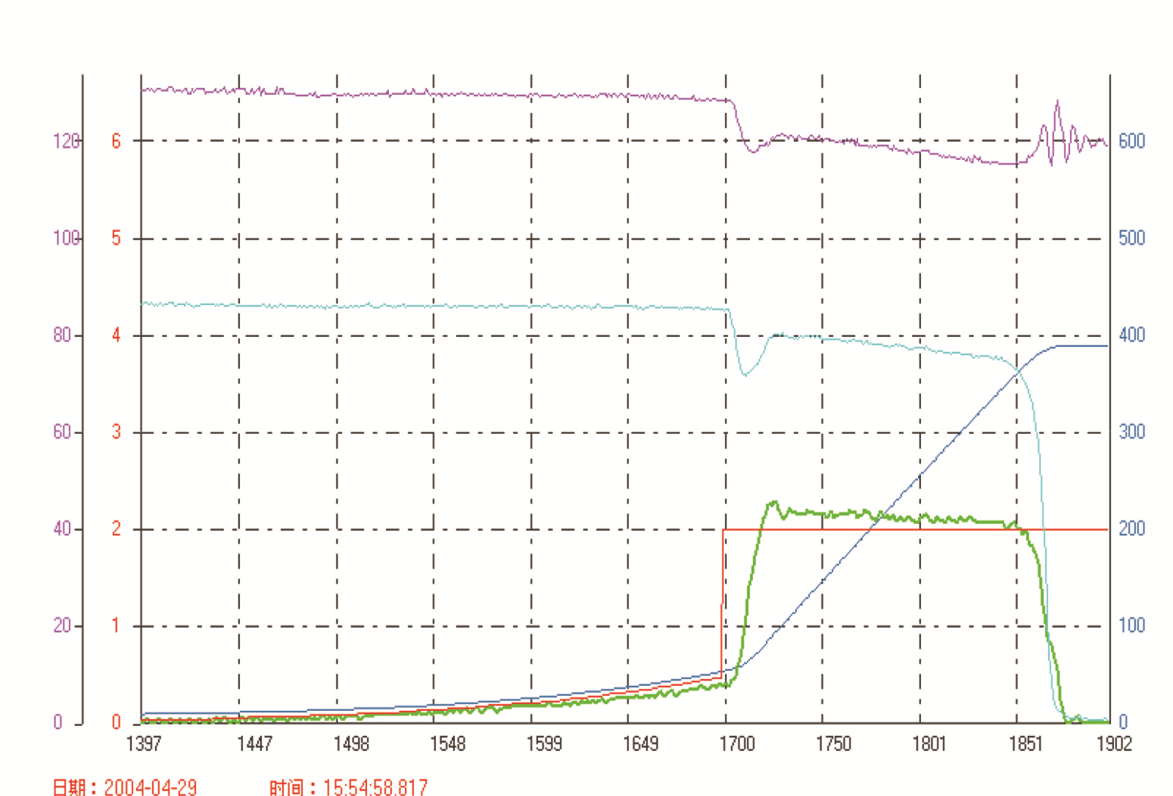

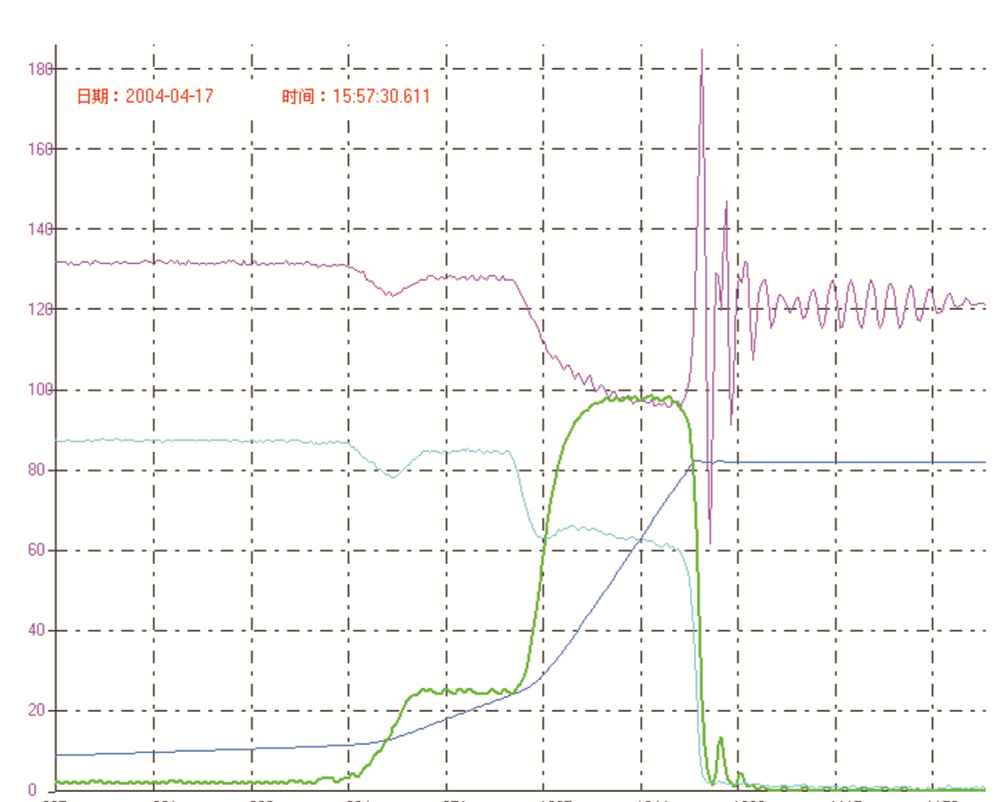

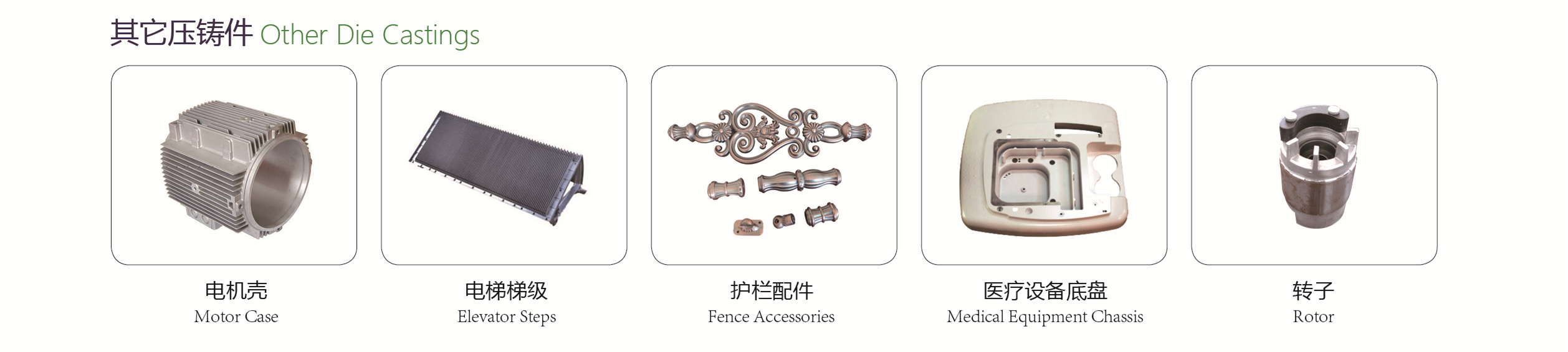

Realtime Control System of High Pressure Die Cast Machine

Accurate Close Loop Control Technology

1. Multistep velocity control, up to ten steps during shooting.

2. Real time control cycle -1ms.

3. High precision measurement of the possion, velocity, force of the cylinder values and real-time feedback close loop control.

4. Uniform acceleration function

Braking At The End Of The High Speed Funtion

1. Improve casting product quality eftetively.

2. Reduce the gas hole ratio effetively of die casting parts.

3. Start without impact, accurately multistep velocity control, the uniform accleration function can improve die cast product surface quality and reduce the air hole ratio.

4. Non-flash technology.

5. Braking at the end of the high speed funtion, quick reply of reduce pressure & speed, avoid the impact & flash, prolong die tool life.

Steadly Reliably Repeatablity

1. Repeated accurncy of the shooting velocity ≦2%.

2. The injection curve is stored and compared according to 100 groups of cycles. Product detection alarm.

3. High stability to ensure consistent product quality.

LZ Die Casting Machine Before and After Sales Services:

Before Sales Services

Provide pre-sales consultation such as investment budget and plant planning, so as to make the customer's plant design reasonable, standardized and save costs.

Exworks test

Continuous grounding resistance test

Injection speed test

Clamping force test

Electric control system test

Machine appearance inspection

Full load test for more than 72 hours

After Sales Services

By guiding customers to install the water and electricity of die casting machines, adjusting new machines. Training customers' technicians and operators. The machine placement is standardized and reasonable. Enable relevant personnel to be familiar with the machine operation and maintance.

Provide FREE standard spare parts together with machine.

Install die casting machine.

Trainning Die casting operator.

Any questions be replied by email, video, photos within 24hr.

Engineer guide your operater to work and adjust machine by video on line.

Quality guarantee period: 12 months after machine put into operation.

If the equipment fails during the guarantee peirod, the manufacturer shall repair and replace accessories free of charge.

Application of Cold Chamber Die Casting Mahine:

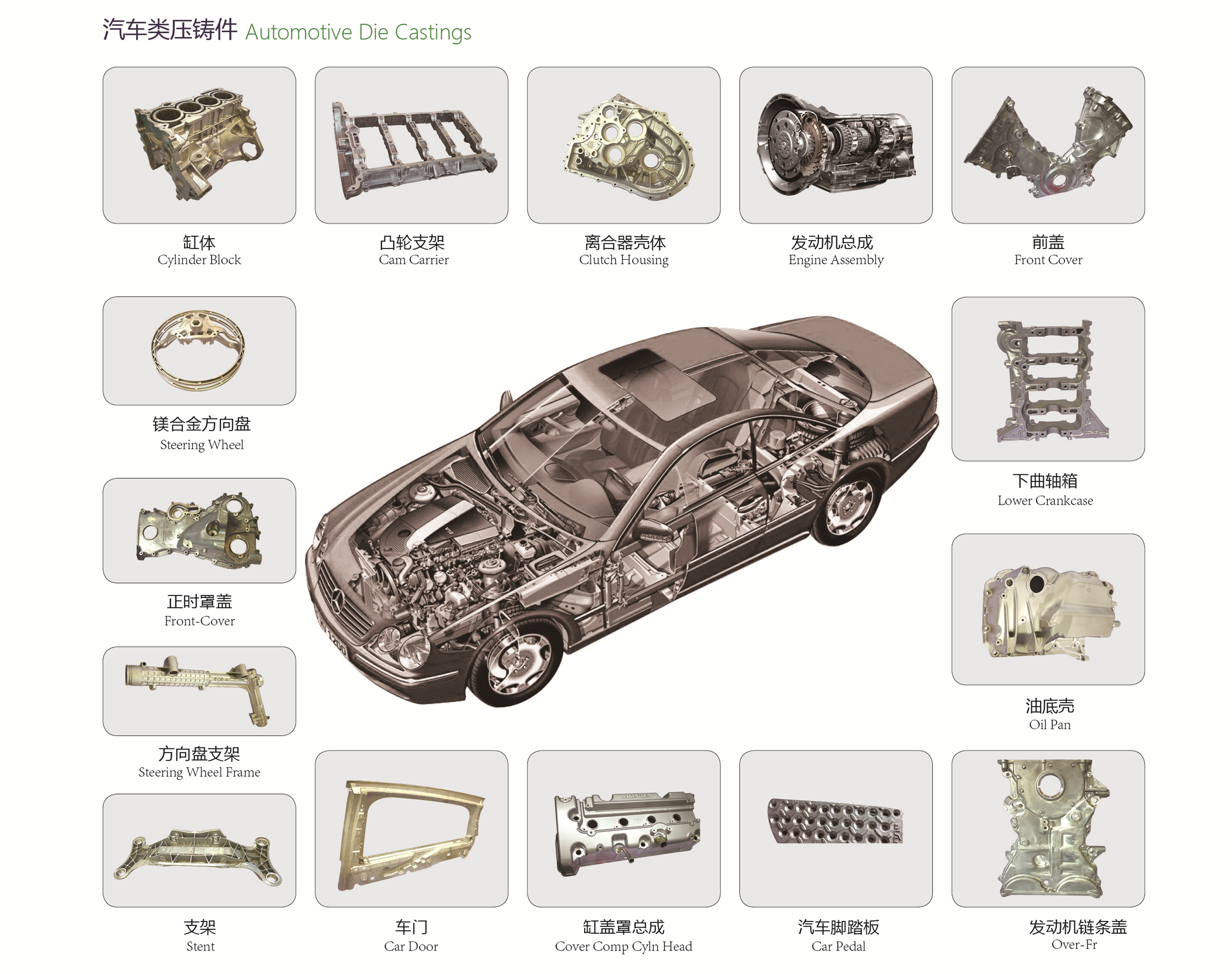

Automotive Die Casting Parts

Kitchen and Toilet Appliances Die Casting Parts

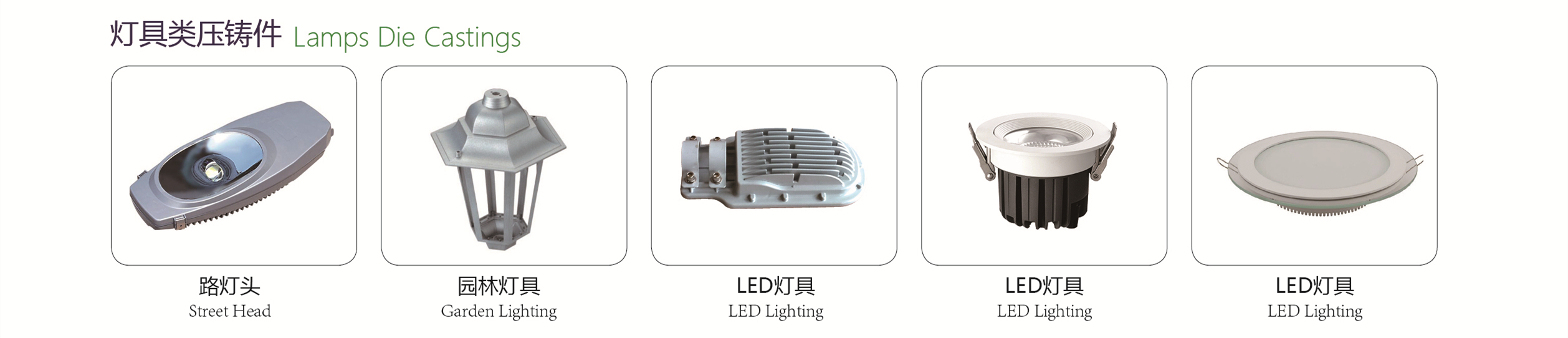

Lamps Die Casting Parts

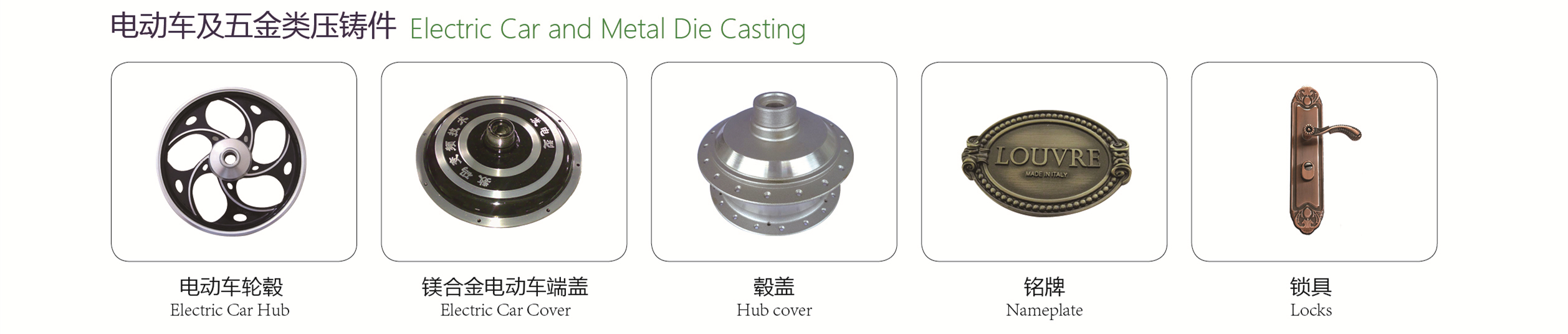

Electric Cars and Metal Hardware Die Casting Parts

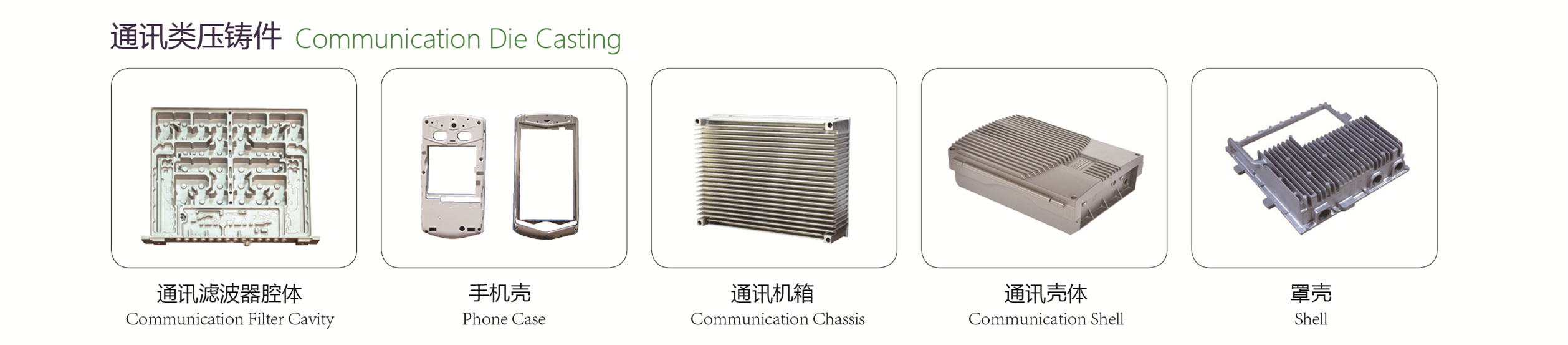

Tel-Communication Die Casting Parts

Garden Machinery and Power Tools Die Casting Parts

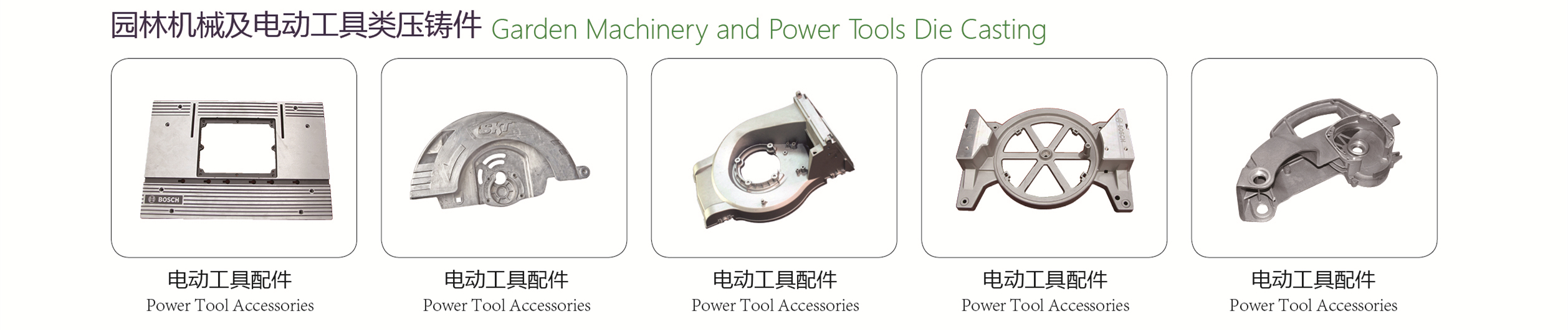

Other Die Casting Parts

Servo driven die casting machine

Servo driven system is an advisable choice for die casting machine factory. It features:

Energy saving

Rapid response and improved efficiency

Stable pressure and precision

High repetition accuracy

High speed and large lifting flow

Connection mode to improve heat dissipation performance

More information about our 160T Cold Chamber Hydraulic Pressure Die Casting Machine Service & Price, Please email us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论