Type 500 Spine or Grid die casting machine used to produce tubular positive spine which length less than 500mm. Details of 500 spine making machine: cnkylt@aliyun.com

Type 500 Lead Acid Battery Positive Plate Spine/Grid Die Casting Machine used to manufacturer tubular grids which length shorter than 500mm. The machine is manual operated. It consists a die casting machine, a grid casting mold, a cutting machine.

500 Grid Casting Machine Instructions and Operating Procedures:

Type and size of the grids:

1.Grid length, 2v 15tube, single, L≤430mm, double, L≤470mm

2.Grid length, 12v, single, L≤300mm, double, L≤210mm

Tubular Positive Plate Spine Pressure Casting Machine Technical Specifications (Type 500):

A. Production capacity: ≥2 shot per minute

B. Power supply: 380V, 3P, 50Hz or customized

C. Electricity consumes : 55kw

D. Pump motor: 15kw

E. Mould heater: 0.4KWX4=1.6KW

F. Lead pot heater: 6KWX6=36KW

G.Nozzle heater; 0.35KWX6=2.1KW

H.Mould lifter motor : 0.37KW =0.37KW

I. Lead melting pot capacity :1800 kg

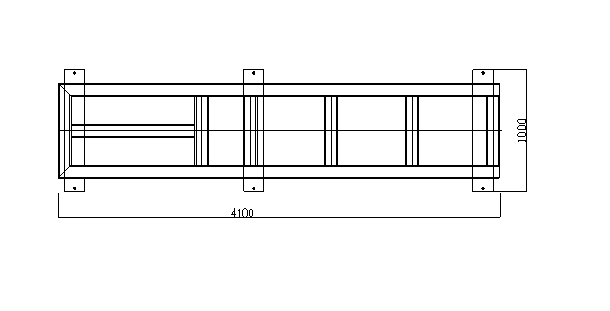

J. Machine size (LWH):4100*1000*1900MM

K.Machine weight: 4T

L.Mold-release agent

Type 500 spine/grid die casting machine need one person to operate casting machine and cutting machine.

Equipment installation:

Necessary facilities

Electricity, cooling water, compressed air, lead fume ventilation pipe for exhaust.

(Technical parameters: power 50kwh ,compressed air 0.1m3/min, 0.6MPa; water consumption 240l/h)

Concrete Floor

As die casting machine is horizontal type, the cement floor must flat. Concrete deepth at least 100mm.

Cooling water

Cooling water is used to cool the mould and the oil. Normal water, circulating water is allowed. If the die casting grid has flash and burr, need to increase the die locking pressure . The locking pressure should be adjusted slowly. Same time the system pressure also be adjust. And to find the appropriate value.

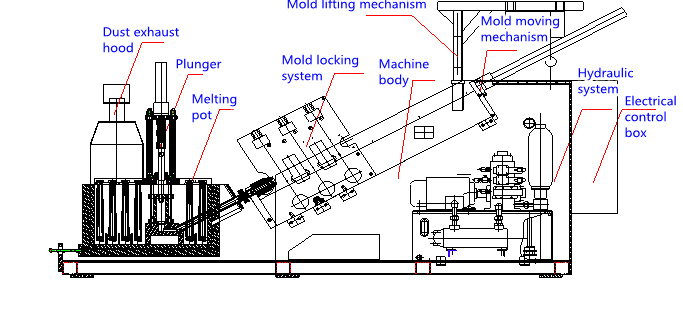

Battery Plate Grid Casting Machine Equipment components:

1. Lead Pot

Lead pot consist: lead pump, injection cylinder, heating pipe, pot body, and heat preservation layer, etc.

Lead pot capacity:1800kg

specifications:380V、6KWX6=36KW

2. Machine Mold Locking Mechanism

The mould locking system consist of locking cylinders, the mold release cylinders and the mould plate.

3. Grid Die Casting Mould

Mold material:H13 steel

Mold size: 35 thick X360 wide x620 long mm

Place the mould to the fixed position with lifting tool, fixed the mould, connected with the heating pipe and the thermocouple.

4.Grid Cutting Machine

Spine cutting machine drives by compressor. Cutting blade material is T8 or 45# steel.

Type 500 Battery Positive Spine/Grid Pressure Die Casting Machine Operating procedures:

1.Before work, to check the reliability of the connection of water, electricity, etc. of equipment。

2.Open power control cupboard door, close the main power switch and the separate switch;

3.Start the power, select manual state to check mold moving, mold locking action.Don't oprate injection action at this time.

4.Turn on the lead pot heating switch. The lead pot heating takes about 2.5 hours.

5.Lead pot temperature heated to about 350 degrees, then to heat the mold and nozzle.

6.When all the temperatures are up to the required values, start the trial run of the equipment. Before starting the machine, check whether the lead melts at the nozzle with steel bars. Manual operation , check the machine. If there is no fault, automatic cycle can be started.

7.After grid picked up from die cavity, it is necessary to check and clean the impurities in the mold.

If the casted grid is not full, has flash or burr, the system pressure and the injection pressure should be adjusted. The general adjusting rule is that the injection pressure should be increased when the grid is not full, the locking pressure should be increased when the flying edge is unsatisfied.

8.When the grid sticks in the mould cavity, the mold release agent should be used.

9.when the mold nozzle temperature is too high, damp cloth or spray gun can be used to cool nozzle localized.

Battery Spine Casting Machine Equipment maintenance and repair (T500):

Die casting Machine is metallurgical equipment, it is working in high temperature and adverse impact environment. Regular maintenance and repair of equipment is necessary, the specific matters are as follows:

1.Hydraulic system

The common failures of hydraulic system of the equipment are:

When the hydraulic system is repaired, the unloading switch in front of the accumulator must be loosened. And the oil in the system must be discharged into the oil tank to avoid oil spilling out. Please confirm that the switch is off before turning on.

Daily maintenance:

-Check the tank oil level frequently.

-Check the oil temperature;.

-Check the operation of each valve.

-Check oil leakage in pipes and cylinders.

First use the equipment, change the oil once a half year, and clean up the system every year。

2. Electrical system

Domestic and international famous brands are used in electrical systems. Some parts are easy to break down for frequent use.

The main failures are as follows:

Schematic diagram of lead acid battery tubular positive plate spine pressure casting equipment organization:

More information and price of Type 500 Battery Positive Spine/Grid Pressure Die Casting Machine, Mould or Production line, please contact us: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论