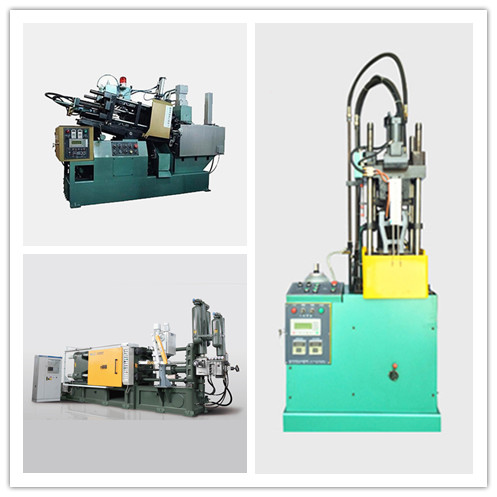

Zinc/Zamak Die Casting Machine types: Horizontal Cold Chamber Die Casting Machine Tonnage:150T ~ 2000T; Horizontal & Vertical Hot Chamber Die Casting Machine Tonnage: 12T, 20T, 30T. More information, please Email: cnkylt@aliyun.com

Zinc die casting machine or Zamak/Zinc alloy injection machine. Zinc metal alloy die casting machinery inject liquid zinc to die casting mould with high pressure. With this character, this casting machinery also named: high pressure zinc injection machine, zinc alloy pressure die casting machine, pressure zinc injection machine etc.

What is zinc die casting?

Zinc die casting process is forcing molten zinc alloy through die casting machine cold chamber or hot chamber into pressure die/mould cavities to produce zinc die casting parts.

Zinc die casting process involves 3key parts: zinc die casting machine, zinc alloy melting furnace, zinc die casting mould (zinc pressure die).

Types of zinc die casting machine:

Zinc zamak die casting machines types: horizontal cold chamber die casting machine, horizontal hot chamber die casting machine, vertical hot chamber die casting machine.

Zinc die casting process:

Zinc can use hot and cold chamber casting processes.

Hot chamber die casting process:

Within the zinc hot chamber die casting process the injection mechanism of a hot chamber machine is connect with meting furnace, the injection plunger immersed in molten zinc alloy.

Cold chamber die casting process:

Zinc zamak alloy cold chamber die casting is same with aluminum die casting process.

The zinc cold chamber die casting process the injection mechanism of a cold chamber machine is separate with melting furnace, which need ladle to pour molten zinc alloy from melting pot to die casting machine cold chamber by manual or robot.

How to choose suitable zinc zamak die casting machines?

The use of zinc die casting machine depends on zinc die casting products weight and project area.

1. Big heavy zinc alloy die casting products use horizontal cold chamber die casting machine. For example, chair structure part, machine part, agriculture machinery mechanism part etc.

2. Small zinc die casting parts use zinc hot chamber die casting machine. And, zinc hot chamber die casting machine can be classified to horizontal version and vertical version.

The usage of horizontal zinc hot chamber die casting machine:

Such as: metal zipper slider, zipper puller, electric zinc connector, Signal distributor (SPLITTER) box, which can use 12T, 20T horizontal hot chamber die casting machine.

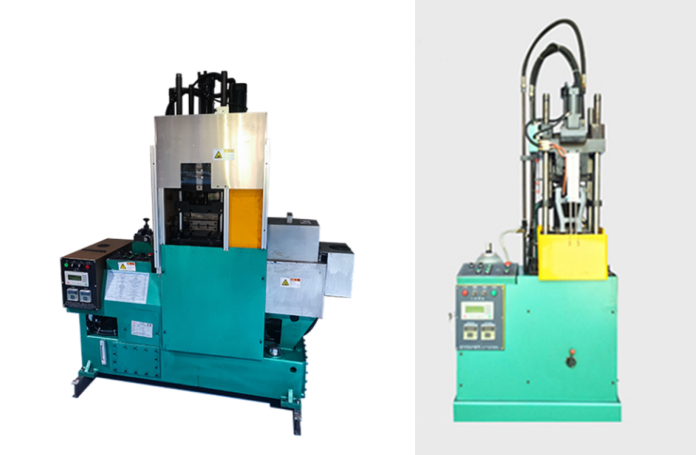

The usage of vertical zinc hot chamber pressure die casting machine:

Such as: brake wire/ cable of car, bike or motorcycle. The wire or cable need cast zinc terminal at the wire end as per design, that need use our 12T or 20T vertical zinc alloy die casting machine.

Brake wire with zinc end terminal machine test video:

Youtube: https://youtu.be/cBZXtBaEbAk

As zinc die casting machine manufacturer and supplier, we sell Horizontal Cold Chamber Zinc Alloy Die Casting Machine, Horizontal Hot Chamber Zinc Die Casting Machine, Vertical Hot Chamber Zinc Die Casting Machine.

And, as per clients' requirement to design die casting mould. Mould test and free samples are allowed.

Zinc Die Casting Machine Price:

Different zinc die casting project chooses different machine, so the zinc die casting machine price are big different.

Small Zinc Hot Chamber Pressure Injection Machine is cheaper than Big scale Zind Alloy Horizontal Cold Chamber Die Casting Machine. Manual zinc die casting process is cheaper than automatic zinc die cast process.

Same reason, zinc die casting mould used in hot chamber injection machine is cheaper than cold chamber machine mould. Because hot chamber machine moulds normally is more smaller. Of course, zinc cast part structure and precision also is the key element of mould cost.

Knowledge about zinc alloy material and zinc die casting

What is zinc die cast material?

Zinc die casting alloys types:

Die cast Zinc Zamak #2, #3, #5, #7, ZA8 and ZA27. Zamak #3, #5 are widely used in die casting process.

Advantages of Zinc Alloy Die Casting & Why is zinc used for die casting?Is zinc easy to cast?

Zinc die casting alloys have excellent strength, toughness, firmness, performance and cost-effective efficiency than other alloys. The zinc alloy die casting advantages:

Excellent Castability – Zinc alloy has good fluidity. Thinner, more intricate and complex die casting parts can be produced. We can do machining with the zinc part directly, do not need secondary operations that are often necessary for aluminum and magnesium alloys.

Shortened Cycle Time – If the zinc utilizes a hot chamber casting process, one minutes can inject 4 to 7 times per minute. Compare with aluminum cold chamber die casting process, which one minute has 2 or 3 shots. We can note that zinc can provide increased overall savings due to shortened cycle times.

Long Die Life - Zinc die casting mould life is about 200000~300000 times. Due to the low melting temperature of zinc, dies for zinc parts can last up to 10 times longer than dies used for aluminum alloy castings (aluminum die casting mould life is about 50000~80000times).

Good Mechanical Qualities – Zinc alloy is stronger than other metals, without the need for secondary processing. Excellent die cast surface and mechanical quality saves production cost of finished zinc products.

Zinc die casting service:

We have cold &hot chamber die casting machine to produce zinc die casting products as per clients drawing or sample. Zinc die casting mould, Trimming, Drilling, Tapping, CNC machining, Painting, Powder Coating, Plating, Electrophoresis is allowed.

More information about our Zinc Die Casting Machine and Zinc Die Casting Service, Please email us: cnkylt@aliyun.com.

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论