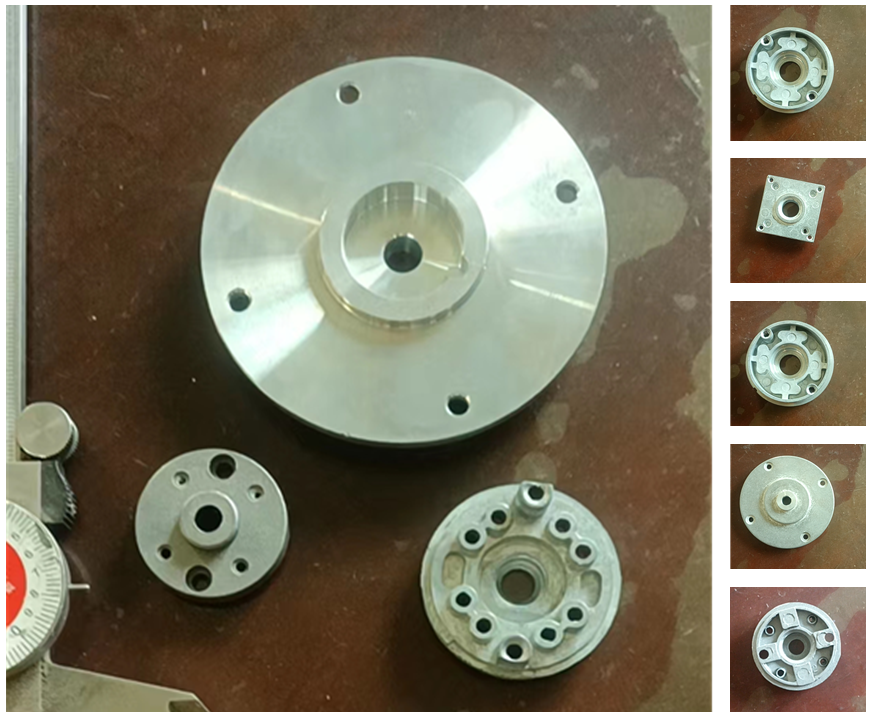

This is a Zinc/Zamak die casting project from a big Home appliances product factory. It is a zinc/zamak parts used in juicer machine.

Follows our meeting details for the Zamak die casting project:

We found from your web site you are professional on ZAMAK product was interested by us as some parts, please check attached drawing and advise if you can supply this part.

Do you have some parts like my projects?

Yes, Here is our samples show.

Could you quote for our Zamak metal plate now?

Yes, i will reply my email. Please kindly check your mailbox.

Shall we pay mould charge to receive samples? Can u send me some samples according to our drawing?

For die casting mould, 50% as deposit. rest be paid after your engineer confirmed samples.

The Zamak part as an insert part be injected together with plastic. Normally made from Copper, Aluminum, Zamak alloy.

How to keep the balance, it is used in Juicer high rotation? It should be balance. What is your idea? This part were merge inside of this part, and will rotate 6000-12000 Rms in Juicer machine.

Keep the M5,M6 in center and when you plastic injection have a good concentricity, that is ok. From photo, the plastic part is big and metal plate is only a small part, plastic is key element for whole part balance.

Yes, but the zamak part is very important. Should be balance. And how about your surface finishing?

i see, we will keep parts obey drawing requirement. Surface is shacking polish. Are you meet any problem about non-balance? maybe you can give me some idea. if you have some experience about balance problem, you can let me know. we will consider and analysis.

Actually now we are producing this part with CNC machine from round bar and balance no problem.

Our suggestions:

1. The key of balance is the M5,M6 concentricity. our quotation basis on M5/M6 directly from mold. When we test mold samples, we can check it firstly.

2. if the concentricity is not good, that need turned machining.

We make M5,M6 thread from mold firstly. And send samples to you for checking. if not good, we will modify mold and adopt CNC turning.

More information about KYLT Metal Die Casting & Plastic Molding Services, CNC Machining Services and CNC Turned Parts, Milling Parts, Please contact: stonechenpeng@aliyun.com +008615195010186

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology:

评论

发表评论