Switch socket panel be used in smarthome control system(SCS). OEM service as per customers’ design, provide mold making and plastic moulding service. Service email: cnkylt@aliyun.com

Moulding plastic switch socket panel specification:

| Product name | Wall switch socket panel (SCS system) |

| Color | White |

| Material | PC |

| Feature | Fireproof and waterproof |

| OEM | Accept |

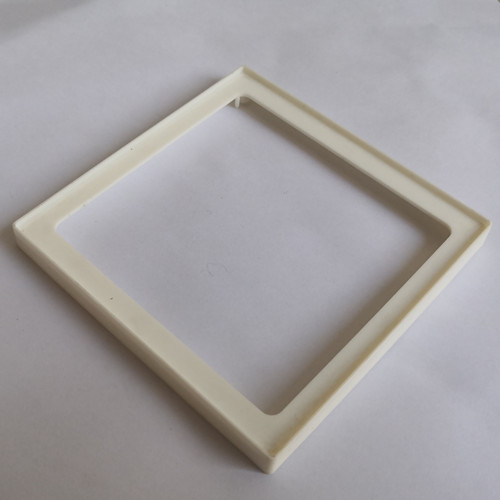

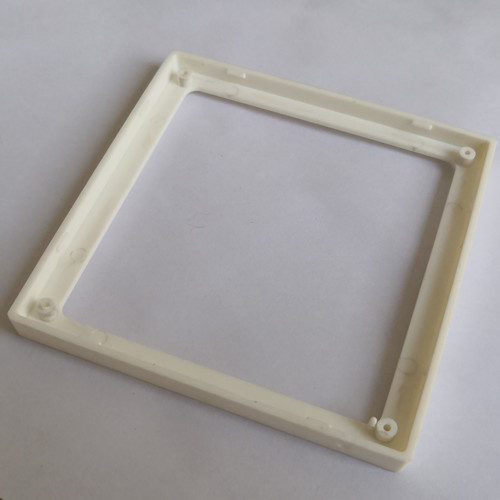

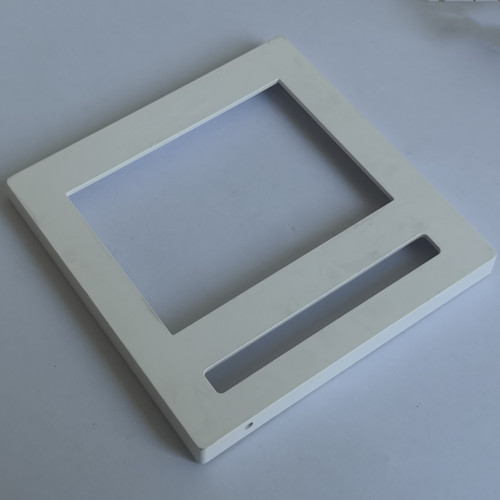

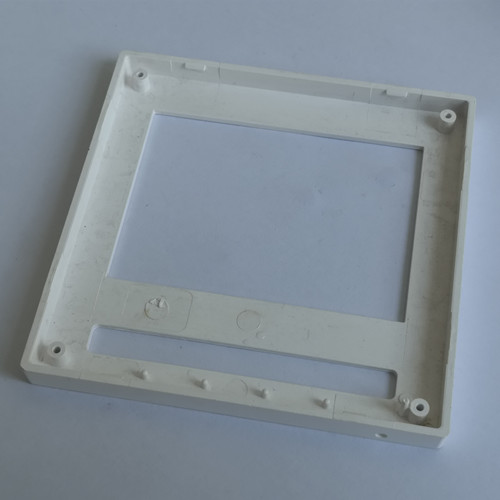

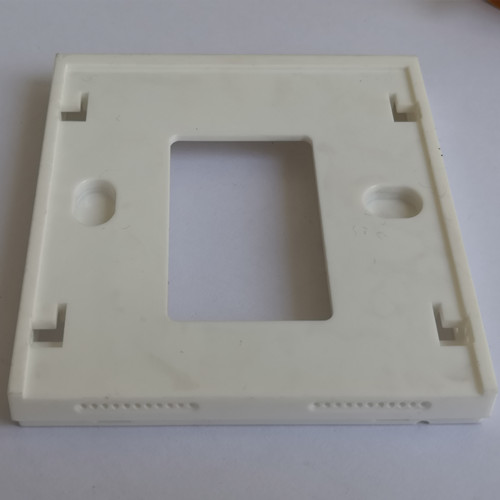

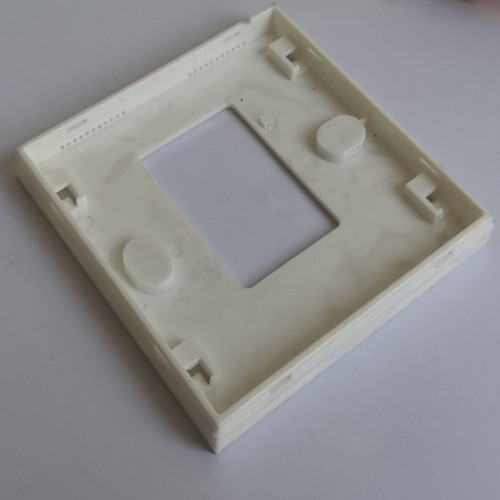

Wall switch socket panel plastic parts photos show:

SWITCH SOCKET PANEL FRAME

Front side of switch socket panel frame

Back side of switch socket panel frame

SWITCH SOCKET PANEL COVER

(Square) switch socket panel cover front side structure

(Square) switch socket panel cover back side structure

(Round) switch socket panel cover front side structure

(Round) switch socket panel cover back side structure

(Buttons) switch socket panel cover front side structure

(Buttons) switch socket panel cover back side structure

switch socket panel assembly part front side structure

switch socket panel assembly part back side structure

flame resistant cover front structure

More information and free quote about all kinds of switch socket panel plastic molding service, mold making service , please email: cnkylt@aliyun.com

评论

发表评论