A good mechanical process engineer must be a good processing equipment application engineer, who is proficient in all kinds of knowledge of the machine tools.

Introduce the most common turning, milling, planing, grinding, boring, drilling, wire cutting and other processing equipment in the mechanical processing industry, and understand the type, scope of application, structural characteristics and processing accuracy of these processing equipment.

Lathe

1) TYPE OF LATHE

The types of lathes include: instrument lathes, single axle automatic lathes, multi axle automatic or semi-automatic lathes, return wheel or turret lathes, crankshaft and camshaft lathes, vertical lathes, floor and horizontal lathes, profiling and Multi Tool lathes, axle spindles and gear cutting lathes, etc. Vertical lathes and horizontal lathes are commonly used in the machinery industry.

2) APPLICABLE SCOPE OF LATHE PROCESSING

A. The horizontal lathe is suitable for turning inner and outer cylindrical surfaces, conical surfaces, formed rotating surfaces and annular grooves, turning sections and various threads, and can be used for drilling, reaming, reaming, tapping, threading, knurling and other processes.

B. Vertical lathes are applicable to the processing of various rack and shell parts, as well as the processing of internal and external cylindrical surfaces, conical surfaces, end faces, grooves, cutting, drilling, expanding, reaming, etc. of various parts. With the help of additional devices, processing procedures such as threading, end faces, profiling, milling and grinding can also be realized.

3) MACHINING ACCURACY OF LATHE

A. The machining accuracy of the general horizontal lathe is as follows:

Roundness: 0.015mm; Cylindricity: 0.02/150mm; Flatness 0.02/ ¢ 150mm; Surface roughness: 1.6ra/ μ m。

B. The machining accuracy of the vertical lathe is as follows:

Roundness: 0.02mm; Cylindricity: 0.01mm; Flatness 0.03mm.

Milling machine

1) TYPE OF MILLING MACHINE

The types of milling machines include: instrument milling machine, cantilever and ram milling machine, gantry milling machine, plane milling machine, profiling milling machine, vertical lifting table milling machine, horizontal lifting table milling machine, bed milling machine, tool milling machine, etc. Vertical machining centers and gantry machining centers are commonly used in the machinery industry.

2) APPLICABLE SCOPE OF MILLING MACHINE PROCESSING

There are too many kinds and structures of milling machines, and there are great differences in their applicability. Here we only introduce the most commonly used vertical machining centers and gantry machining centers.

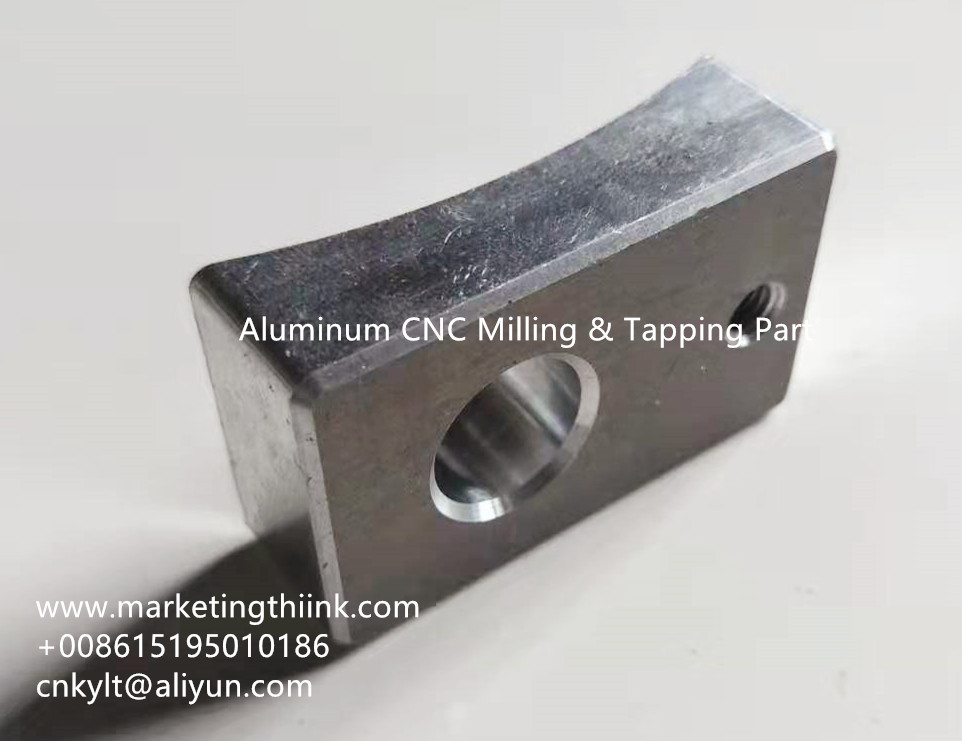

A. Vertical machining center: the vertical machining center is actually a vertical CNC milling machine with a tool library. Its main feature is that it uses multi edge rotary tools for cutting, which can process planes, grooves, gear parts, helical surfaces and various curved surfaces. Especially with the application of numerical control technology, the processing range of this type of machine tools has also been greatly improved, in addition to various milling operations, It can also drill, bore, ream and tap the thread of the workpiece.

B. Gantry machining center: compared with vertical machining center, gantry machining center is a composite application of CNC gantry milling machine and tool magazine. In terms of processing range, the gantry machining center has almost all the processing capabilities of ordinary vertical machining centers, and can adapt to the processing of larger tools in terms of the overall dimensions of parts. At the same time, it also has great advantages in processing efficiency and processing accuracy, especially the practical application of the five axis combined gantry machining center, its processing range has also been greatly improved.

3) MACHINING ACCURACY OF MILLING MACHINE:

A. Vertical machining center:

Flatness: 0.025/300mm; Coarse excess: 1.6ra/ μ m。

B. Gantry machining center:

Flatness: 0.025/300mm; Coarse excess: 2.5ra/ μ m。

Planer

1) TYPE OF PLANER

Compared with lathes and milling machines, the types of planers are much less. The typical types are: cantilever planer, gantry planer, shaper, edge and mold planer, etc. In the machinery industry, shapers and planers are the most widely used and widely used.

2) APPLICATION SCOPE OF PLANER PROCESSING

The planing motion of the planer is mainly the periodic round-trip linear motion relative to the processing workpiece. Its applicable planing part features are mostly the processing of plane, inclined plane and concave convex surface, and can also be planed for various curved surfaces. However, due to the limitations of its own processing characteristics, the speed of processing and planing is not too high, so the processing efficiency is relatively low.

3) MACHINING ACCURACY OF PLANER

The accuracy of planing can generally reach the accuracy level of it10-it7, especially for the machining of long guide rail surface of some large machine tools, which can even replace grinding.

Grinding machine

1) TYPE OF GRINDER

There are many kinds of grinding machines, which can be divided into: instrument grinding machines, cylindrical grinding machines, internal grinding machines, grinding machines, coordinate grinding machines, guide rail grinding machines, tool edge grinding machines, surface and end grinding machines, crankshaft camshaft spline and roll grinding machines, tool grinding machines, superfinishing machines, internal honing machines, external and other honing machines, polishing machines, abrasive belt polishing and grinding machines. There are many types of tool grinding and grinding machines, indexable blade grinding machines, grinding machines, ball bearing ring groove grinding machines, roller bearing ring raceway grinding machines, bearing ring superfinishing machines, blade grinding machines, roller processing machines, steel ball processing machines, valve piston and piston ring grinding machines, automobile and tractor grinding machines, etc. Here we will specifically talk about cylindrical grinder and surface grinder.

2) APPLICABLE SCOPE OF GRINDING MACHINE PROCESSING

A. Cylindrical grinding machines and cylindrical grinding machines are mainly used to process cylindrical surfaces, conical surfaces or other external surfaces of rotating bodies and shaft shoulder end faces. Because of their good processing adaptability and processing accuracy, they are widely used in the processing of some high-precision parts in machining.

B. The surface grinder is mainly used to process the surface of parts such as plane, step surface and side.

3) MACHINING ACCURACY OF GRINDING MACHINE

A. Machining accuracy of cylindrical grinder:

Roundness and cylindricity: 0.003mm; Surface roughness: 0.32ra/ μ m。

B. Machining accuracy of surface grinder:

Parallelism: 0.01/300mm; Surface roughness: 0.8ra/ μ m。

Boring machine

1) TYPE OF BORING MACHINE

Boring machines can be divided into the following types: deep hole boring machines, coordinate boring machines, vertical boring machines, horizontal milling and boring machines, fine boring machines, boring machines for automobile and tractor repair, etc. The most commonly used boring machine is coordinate boring machine.

2) APPLICATION SCOPE OF BORING MACHINE

Coordinate boring machine is a kind of precision machine tool with precision coordinate positioning device, which is mainly used for boring hole systems with high requirements for size, shape and position accuracy. It can be used for drilling, reaming, reaming, end face, grooving, milling surface and other processing, as well as coordinate measurement, precision calibration, marking and other work.

3) MACHINING ACCURACY OF BORING MACHINE

The aperture accuracy processed by coordinate boring machine is generally it6-7, and the surface roughness is 0.4-0.8ra/ μ m。

Drilling machine

1) TYPE OF DRILLING MACHINE

Drilling machines can be divided into the following types: coordinate boring machines, deep hole drilling machines, radial drilling machines, bench drilling machines, vertical drilling machines, horizontal drilling machines, milling drilling machines, center hole drilling machines, etc. The most common is radial drilling machine.

2) APPLICABLE SCOPE OF DRILLING MACHINE PROCESSING

We mainly describe the rocker drill. Drilling machine is to drill various types of holes. In addition to drilling, it can also realize processing procedures such as reaming, reaming, drilling, tapping and so on. Its main disadvantage is that the accuracy of hole system position is not high. Therefore, we usually do not choose drilling machine to realize some parts that require high accuracy of hole system position.

3) MACHINING ACCURACY OF DRILLING MACHINE

Because there is basically no machining accuracy, just drilling a hole.

Wire cutting

1) TYPE OF WIRE CUTTING

Wire EDM cutting machines can be divided into high-speed reciprocating wire cut electrical discharge machining (commonly known as “fast wire cutting”) Low speed one-way walk Wire cut electrical discharge machining (commonly known as “slow wire”) and vertical wire electrical discharge machining machine tool with rotation wire.

2) MACHINING ACCURACY OF WEDM

The wire speed of fast wire EDM is 6 ~ 12 mm / s. the electrode wire moves back and forth at high speed, and the cutting accuracy is poor. Medium wire EDM is a new technology developed in recent years, which realizes the function of frequency conversion and multiple cutting based on fast wire EDM. The wire speed of slow wire EDM is 0.2mm/s, and the electrode wire makes low-speed unidirectional movement, with high cutting accuracy.

MORE KYLT MACHINING SERVICES & PRODUCTS INFORMATION:

Visit CNC Milling Parts, EDM/WEDM Parts , CNC Machining Service, Rapid Prototype for your reference.

To get more information about KYLT products and services, please e-mail to cnkylt@aliyun.com to get a FREE quote.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology:

评论

发表评论