Die casting is a process that involves injecting molten metal into a mold to create a specific shape. A die casting machine is a tool used to carry out this process efficiently and effectively. These machines are used in a variety of industries, including automotive, aerospace, consumer goods, construction, and medical.

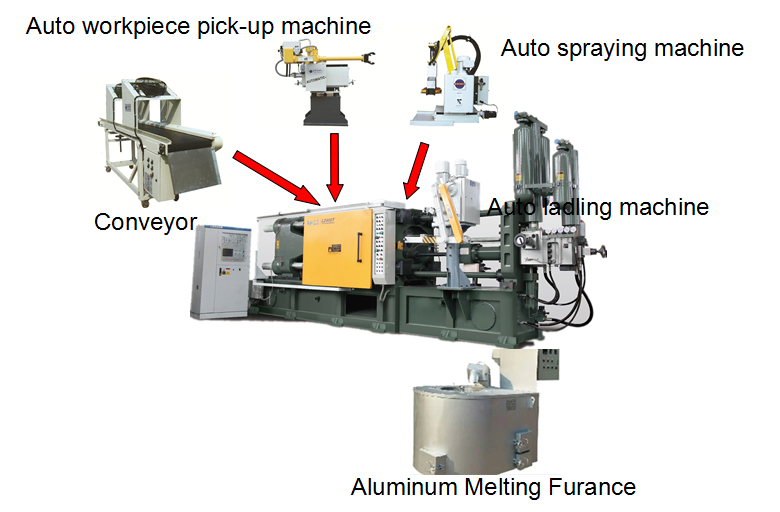

Above is die casting machine and die casting parts show.

The Die Casting Machine: How It Works

Die casting machines consist of two parts: the injection system and the clamping unit.

The injection system includes the furnace, where the metal is melted; and the shot chamber, where the molten metal is injected into the mold. The clamping unit consists of two platens that hold the mold and apply pressure to keep it closed during the injection process.

The die casting process begins with the furnace melting the metal, which is then transported to the shot chamber using a ladle or automatic pouring device. The molten metal is then injected into the mold cavity under high pressure, which ensures that the material fills the entire cavity and solidifies quickly. Once the metal has cooled and solidified, the mold is opened, and the part is ejected from the machine.

Photo shows a Die casting machine working process.

Types of Die Casting Machines

There are two main types of die casting machines: Cold chamber machines and Hot chamber machines.

Cold Chamber Die Casting Machines

Cold chamber die casting machines are used for metals with high melting points, such as Aluminum alloy die casting parts and Copper alloy die casting parts. The furnace is separate from the injection chamber, which is cooled to prevent the molten metal from solidifying. The metal is then transferred to the injection chamber using a ladle or automatic pouring device.

Hot Chamber Die Casting Machines

Hot chamber die casting machines are used for metals with low melting points, such as Zinc/Zamak and magnesium alloys. The furnace and injection chamber are combined into one unit, which is kept at a high temperature to prevent the metal from solidifying. Using a postion, the molten metal be injected into the mold.

How to choose a Die Casting Machine? (Factors to Consider When Choosing a Die Casting Machine)

There are several factors to consider when choosing a die casting machine, including:

The size and shape of the parts being produced.

The type of metal being used.

The production volume required.

The level of automation and technology needed.

The energy efficiency and environmental impact of the machine.

Maintenance and Upkeep of Die Casting Machines

To ensure optimal performance and longevity of die casting machines, regular maintenance and upkeep are essential. This includes:

Regular cleaning and lubrication of machine components.

Monitoring and adjusting machine settings to maintain consistent quality and efficiency.

Replacement of worn or damaged parts.

Regular inspection and testing to identify and address potential issues before they become major problems.

Die casting machine inspection and maintenance

Emerging Trends in Die Casting Machine Technology

The die casting industry is continually evolving, with new technologies and processes emerging to improve efficiency, quality, and sustainability. Some of the emerging trends in die casting machine technology include:

The use of artificial intelligence and machine learning to optimize machine settings and improve quality control.

The development of new, more environmentally friendly alloys for use in die casting.

The adoption of Industry 4.0 technologies, such as the Internet of Things and automation, to streamline production processes and improve efficiency.

Conclusion

Die casting machines are essential tools for producing high-quality metal parts for a wide range of applications and industries. By understanding the key features and considerations involved in choosing, maintaining, and operating these machines, businesses can optimize their production processes and ensure consistent, high-quality output while minimizing their environmental impact.

More informations about Die casting machines and Aluminum/ Zinc (Zamak) Die Casting Parts, please contact us for free quotation: cnkylt@aliyun.com

FAQs

1. What is the difference between cold chamber and hot chamber die casting machines?

Cold chamber die casting machines are used for metals with high melting points, such as aluminum and copper, while hot chamber die casting machines are used for metals with low melting points, such as zinc and magnesium.

2. How do die casting machines improve efficiency and productivity?

Die-casting machines use high pressure to quickly and efficiently fill molds with molten metal, resulting in faster production times and increased productivity.

3. What are some common industries that use die casting machines?

Die cast machines are used in a variety of industries, including automotive, aerospace, consumer goods, construction, and medical.

4. How often should die casting machines be maintained?

Die-cast machines should be regularly maintained and inspected to ensure optimal performance and longevity. The frequency of maintenance may vary depending on the specific machine and production requirements.

5. What are some emerging trends in die casting machine technology?

Some emerging trends in die casting machine technology include the use of artificial intelligence and machine learning, the development of more environmentally friendly alloys, and the adoption of Industry 4.0 technologies.

6. Can die casting machines be used with other materials besides metals?

No, die casting machines are specifically designed for use with metals.

7.What are the main differences between hot and cold chamber die casting machines?

The main difference is that hot chamber die casting machines are used for metals with low melting points, while cold chamber die casting machines are used for metals with high melting points.

8. Are there any safety concerns when using die casting machines?

Yes, there are safety concerns when using die casting machines due to the high temperatures and pressures involved. Proper training and safety protocols should be followed to minimize the risk of accidents.

9. What is the typical lifespan of a die casting machine?

The lifespan of a die casting machine can vary depending on factors such as usage, maintenance, and the specific machine model. However, with proper maintenance and care, a die casting machine can last for many years.

10. Can die casting machines be used for small-scale production?

Yes, die casting machines can be used for small-scale production, but their efficiency and productivity are optimized for high-volume production.

Related Metal Casting Machinery:

Die Casting Machines type:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die casting machines' classification by materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die casting machines' application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论