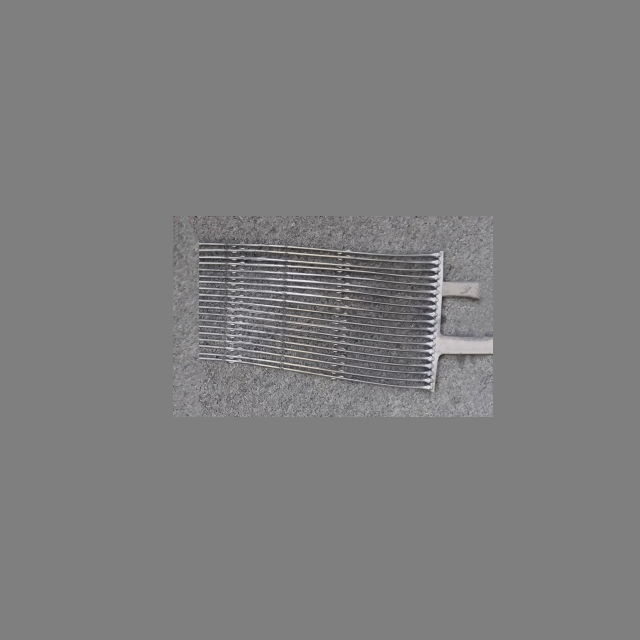

Lead Acid Battery Spine Die Casting Machine(PDC machine, Positive Spine/Grid pressure die casting machines) used to produce tubular positive plates.

Lead Acid Battery Manufacturing with Positive Spine Die Casting Machines:

Meta-description: Discover the benefits of using positive spine die casting machines for manufacturing lead acid batteries. Learn how this technology can improve production efficiency, quality, and durability.

Introduction of Positive Spine/Grid Die Casting Machines

Lead acid batteries have been powering our daily lives for more than a century. They are widely used in various applications, from automotive to industrial, due to their low cost and high reliability. However, the manufacturing process of lead acid batteries is a complex and demanding task that requires specialized equipment and skilled workers. One of the critical components of a lead acid battery is the positive spine, which is responsible for delivering power to the battery's terminals. Traditionally, positive spines are made through a process called gravity casting, which involves pouring molten lead into a mold and waiting for it to solidify. This method is time-consuming and prone to defects, such as porosity, which can compromise the battery's performance and lifespan.

Fortunately, advances in technology have brought about new solutions to improve the manufacturing process of lead acid batteries. One such solution is the use of positive spine die casting machines. In this article, we will explore the benefits of using positive spine die casting machines in manufacturing lead acid batteries.

Battery spine/grid die casting machine types:

Our die casting machine advantages: stable, easy to maintain.

The 700type grid high pressure casting machine with hydraulic mold clamping system, that can make double-spines at one shot.

Basic information of Battery spine/grid die casting machine:

PDC Spine making machine application: to cast tubular positive plates of lead acid battery.

Die casing lead alloy types: Lead antimony alloy, Lead calcium alloy.

Spine PDC machine & Mold working period: Grid Mold 20days, Spine Die Casting Machine 30-40days

Spine/Grid Die Casting Mold Material: H13

Mold life: if everything goes well, 3-5years

Benefits of Positive Spine Die Casting Machines

Positive spine die casting machines are a type of casting equipment that uses high-pressure injection to fill a mold with molten lead. Unlike gravity casting, which relies on gravity to fill the mold, die casting machines can produce more precise and uniform parts with fewer defects. Here are some of the benefits of using positive spine die casting machines in manufacturing lead acid batteries:

1. Improved Production Efficiency

Positive spine die casting machines can produce more parts in less time compared to gravity casting. The high-pressure injection system allows for faster filling of the mold, resulting in shorter cycle times. This translates to higher production rates and lower manufacturing costs.

2. Consistent Quality

Die casting machines can produce parts with consistent quality and dimensional accuracy. The mold design can be optimized to minimize defects and ensure uniformity across parts. This results in higher product quality and reliability.

3. Enhanced Durability

The use of die casting machines can improve the durability of lead acid batteries. The parts produced have a more uniform and dense structure, which enhances their resistance to corrosion and mechanical stress. This translates to longer battery life and improved performance.

How Positive Spine Die Casting Machines Work

Positive spine die casting machines work by injecting molten lead into a mold under high pressure. The process involves several steps:

1. Preparation of the Mold

The mold is prepared by coating it with a release agent to prevent the molten lead from sticking to it. The mold is then closed and clamped shut.

2. Injection of Molten Lead

Molten lead is injected into the mold under high pressure using a plunger. The pressure ensures that the molten lead fills the mold completely and uniformly.

3. Cooling and Ejection of Part

After the molten lead has solidified, the mold is opened, and the part is ejected. The part is then inspected for defects and sent for further processing.

KYLT Industrial is one of the Lead Acid Battery Positive Spine Grid Die casting machines manufacturer & supplier & factory. Get a FREE quotation of your positive spine die casting machine and molds prices: cnkylt@aliyun.com

Conclusion

Lead Acid Battery Positive spine die casting machines are an innovative solution for improving the manufacturing process of lead acid batteries. By using high-pressure injection to fill molds with molten lead, these machines can produce parts with greater precision, consistency, and durability than traditional gravity casting methods. The benefits of using positive spine die casting machines include improved production efficiency, consistent quality, and enhanced durability. With the increasing demand for high-quality, reliable lead acid batteries, the adoption of positive spine die casting machines is becoming more widespread in the industry.

FAQs

1. How much does a positive spine die casting machine cost?

The cost of a positive spine die casting machine depends on its size and capabilities. A small machine can cost around $50,000, while a larger machine can cost upwards of $90,000.

2. Can positive spine die casting machines produce other parts besides positive spines?

Yes. But we only suggest clients only use positive spine die casting machines to produce Positive Spine or Grid.

3. Is the use of positive spine die casting machines environmentally friendly?

Positive spine die casting machines are more environmentally friendly compared to gravity casting machines. The process generates less waste and has a higher material yield, which reduces the environmental impact of lead acid battery manufacturing.

4. What are the maintenance requirements for positive spine die casting machines?

Positive spine die casting machines require regular maintenance to ensure their optimal performance. This includes cleaning, lubrication, and inspection of the machine's components. The frequency of maintenance depends on the machine's usage and the manufacturer's recommendations.

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论