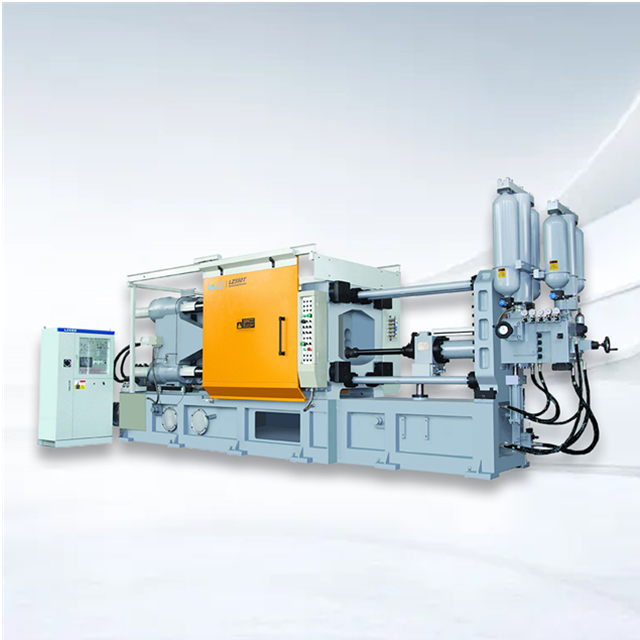

PDC machine (Pressure Die Casting Machine), HPDC machine(High pressure die casting machine).

What are Pressure Die Casting (PDC) Machines?

Pressure die casting machines (PDC machines) are used to produce metal parts with high accuracy, consistency, and speed. These machines use a high-pressure injection system to force molten metal into a die or mold cavity, where it solidifies and takes the shape of the cavity. The resulting parts are strong, precise, and often require little or no additional machining.

PDC Machines Types

There are two main types of pressure die casting machines: Hot chamber machines and Cold chamber machines.

Hot chamber machines are used for metals with low melting points, such as ZAMAK/Zinc, Lead/PB, and Tin alloy. The metal is melted in a furnace that is attached to the machine and then injected into the mold.

Cold chamber machines, are used for metals with high melting points( low melting point alloies are also allowed), such as Copper, Brass, and Aluminum, Magnesium, Zamak/Zinc, Lead/Pb alloy. In this type of machine, the molten metal is poured into a separate chamber and then injected into the mold.

KYLT - PDC/HPDC Pressure Die Casting Machines Type:

Horizontal Cold Chamber PDC/HPDC Machines

Horizontal Hot Chamber PDC/HPDC Machines

Vertical Hot Chamber PDC/HPDC Machines

Lead Acid Battery Positive Spine/Grid PDC Machines

PDC/HPDC Machines Material:

Aluminum PDC/HPDC machine (Aluminum cold chamber die casting machines)

Copper/Brass PDC/HPDC machine (Copper Brass cold chamber die casting machine)

Zinc/Zamak PDC/HPDC machine

(Zamak Zinc cold chamber die casting machine)

(Zinc Zamak hot chamber die casting machine)

Lead/PB PDC/HPDC machine

Lead acid battery positive spine/grid PDC/HPDC machine

PDC Machines Features:

Some common features of PDC Machines ( pressure die casting machines ) include a hydraulic system to control the pressure, a casting chamber, and a mold. The mold is typically made of steel and is designed to produce the desired shape of the part being manufactured. The casting chamber is where the molten metal is injected into the mold under high pressure.

PDC Machines Basic Components

The basic components of a pressure die casting machine include the injection system, the die or mold, and the clamping system. The injection system typically consists of a metal melting furnace, a shot chamber, and a plunger. The metal is melted in the furnace and then transferred to the shot chamber, where it is injected into the die cavity under high pressure.

Die Casting Molds/Dies for PDC Machines

The die casting die or mold is made of two halves, which are closed and clamped together during the casting process. The clamping system provides the necessary force to keep the two halves of the die or mold together during the injection and solidification process. Once the part has solidified, the die is opened and the finished part is ejected.

Pressure die casting machines can produce parts from a variety of metals, including aluminum, magnesium, lead, brass, copper, and zinc. They are commonly used in the automotive industry to produce engine components, transmission parts, and other critical components. They are also used in the aerospace industry to produce complex parts for aircraft and spacecraft. Other industries that rely on pressure die casting machines include electronics, appliances, and medical equipment.

KYLT Industrial is your trustable PDC machines (Pressure Die casting machines) manufacturer & supplier & factory. For PDC machines price & die casting molds prices, please Email us: cnkylt@aliyun.com

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论