Introduction

In today’s rapidly advancing technological landscape, the demand for high-quality injection-molded parts with exceptional aesthetics is on the rise. Industries such as automotive, electronics, and consumer goods require components that not only exhibit excellent mechanical properties but also possess a visually appealing finish. This is where ABS and PC substrates, combined with UV vacuum metallization coating services, play a vital role. In this article, we will delve into the world of ABS, PC substrates, and cutting-edge UV vacuum metallization coating services that enhance their appearance and functionality.

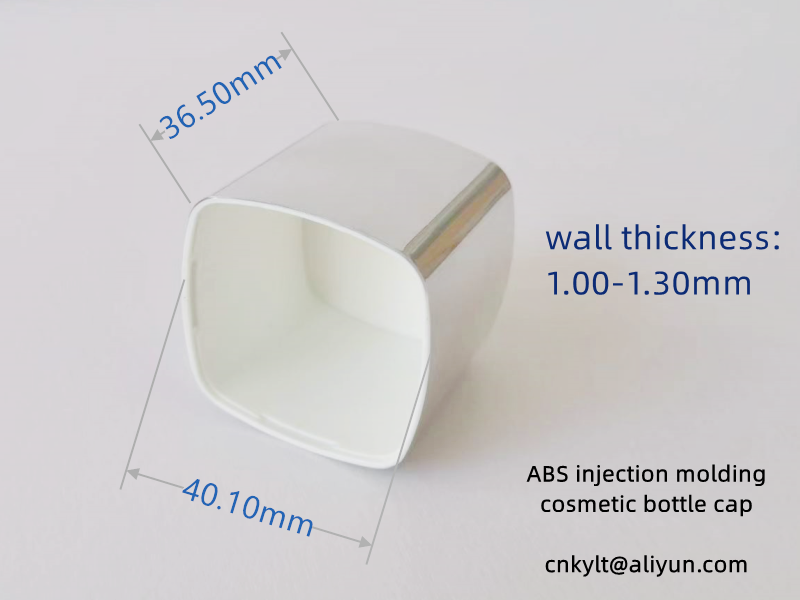

plastic injection molded cosmetic packaging with UV Vacuum Metallization Coating.

(Plastic cosmetic packaging parts making and UV vacuum metallization coating service: cnkylt@aliyun.com)

ABS, PC Substrates by plastic injection molding method

UNDERSTANDING ABS AND PC SUBSTRATES

ABS (Acrylonitrile Butadiene Styrene) and PC (Polycarbonate) substrates are two widely used materials in the field of injection molding. These thermoplastic polymers offer a multitude of advantages, making them an ideal choice for various applications.

ABS: LIGHTWEIGHT AND VERSATILE

ABS is known for its exceptional impact resistance, high strength-to-weight ratio, and excellent dimensional stability. It is widely utilized in the automotive industry for manufacturing components such as interior trim, instrument panels, and bumper grilles. The lightweight nature of ABS makes it an ideal choice for reducing the overall weight of vehicles, leading to improved fuel efficiency.

PC: TOUGHNESS AND TRANSPARENCY

PC substrates boast exceptional mechanical properties, including high impact resistance and superior heat resistance. These properties, coupled with its transparency, make it a preferred material for manufacturing optical lenses, electronic device housings, and automotive lighting components. PC substrates also exhibit excellent electrical insulation properties, making them suitable for applications requiring electrical conductivity.

plastic injection molded cosmetic packaging with UV Vacuum Metallization Coating.

(Plastic cosmetic packaging parts making and UV vacuum metallization coating service: cnkylt@aliyun.com)

THE ROLE OF UV VACUUM METALLIZATION COATING SERVICES

UNLEASHING AESTHETIC BRILLIANCE

UV vacuum metallization coating services elevate the appearance of ABS and PC substrates to a whole new level. This advanced coating technique involves depositing a thin layer of metal onto the surface of the substrate using a vacuum chamber, followed by a UV curing process. The result is a stunning metallic finish that simulates the look of chrome, gold, or other metal coatings.

ENHANCED DURABILITY AND PERFORMANCE

The UV metallization coating not only enhances the visual appeal but also offers additional benefits to the substrate. It provides a protective layer that increases the part’s resistance to scratches, abrasion, and UV radiation. Furthermore, the coating helps improve the part’s overall durability, ensuring longevity and reliable performance in challenging environments.

YOUTUBE Video shows Cosmetic Bottle UV metalized Cap :

https://youtube.com/shorts/MP0GjNzUZ6E

Advantages of ABS, PC Substrates Injection Parts with UV Vacuum Metallization Coating

UNPARALLELED AESTHETICS

With ABS, PC substrates injection parts treated with UV vacuum metallization coating services, manufacturers can achieve a premium metallic finish that adds a touch of elegance to their products. This visually stunning appearance captivates consumers and enhances the perceived value of the end product.

SUPERIOR FUNCTIONALITY

Apart from the striking aesthetics, ABS, PC substrates injection parts with UV vacuum metallization coating services maintain their excellent mechanical properties. The coating does not compromise the substrate’s inherent strengths, such as impact resistance, toughness, and dimensional stability, ensuring that the parts perform exceptionally in their intended applications.

VERSATILITY AND CUSTOMIZATION

ABS and PC substrates, combined with UV vacuum metallization coating services, offer manufacturers unparalleled versatility and customization options. The coating can be tailored to achieve different metal finishes, allowing businesses to meet the unique design preferences of their target audience. Whether it’s a sleek chrome appearance or a lustrous gold finish, the possibilities are endless.

ENHANCED BRAND IMAGE

By integrating ABS and PC substrates injection parts with UV vacuum metallization coating services into their products, companies can significantly enhance their brand image.

ESTABLISHING A DISTINCTIVE IDENTITY

The ABS, PC substrates injection parts with UV vacuum metallization coating services give manufacturers an opportunity to establish a distinctive brand identity. The eye-catching metallic finish sets their products apart from the competition, leaving a lasting impression on consumers. This unique visual appeal can contribute to brand recognition and help businesses stand out in the market.

WIDE RANGE OF APPLICATIONS

The combination of ABS, PC substrates, and UV vacuum metallization coating services opens up a wide range of applications across different industries. From automotive components to consumer electronics and household appliances, these materials and services find use in diverse sectors. Whether it’s interior trims in cars, electronic device casings, or decorative elements, the ABS, PC substrates injection parts with UV vacuum metallization coating services offer versatility and adaptability to various manufacturing needs.

COST-EFFECTIVE SOLUTION

Despite their premium appearance and enhanced functionality, ABS, PC substrates injection parts with UV vacuum metallization coating services provide a cost-effective solution for manufacturers. The materials themselves are relatively affordable, and the coating process is efficient and yields consistent results. This makes it a viable option for businesses looking to achieve a high-quality metallic finish without breaking the bank.

IMPROVED PRODUCT DURABILITY

One of the significant advantages of ABS, PC substrates injection parts with UV vacuum metallization coating services is the added durability they provide. The coating acts as a protective barrier, shielding the parts from everyday wear and tear, such as scratches, impact, and exposure to UV radiation. This not only extends the lifespan of the products but also ensures that they maintain their pristine appearance over time.

STREAMLINED MANUFACTURING PROCESS

The integration of ABS, PC substrates injection parts with UV vacuum metallization coating services into the manufacturing process is seamless and efficient. The injection molding technique allows for precise and intricate designs, ensuring that the parts meet the required specifications. The subsequent application of the UV vacuum metallization coating can be easily incorporated into the production line, making it a streamlined process for manufacturers.

ENVIRONMENTAL FRIENDLINESS

ABS and PC substrates, along with the UV vacuum metallization coating services, promote environmental friendliness in manufacturing. These materials are recyclable, reducing the overall carbon footprint of the production process. Additionally, the coating process itself is environmentally friendly, as it uses minimal chemicals and has low emissions. This aligns with the growing focus on sustainability in the industry and appeals to eco-conscious consumers.

plastic injection molded cosmetic packaging with UV Vacuum Metallization Coating.

(Plastic cosmetic packaging parts making and UV vacuum metallization coating service: cnkylt@aliyun.com)

Frequently Asked Questions (FAQs)

1. WHAT ARE THE KEY ADVANTAGES OF USING ABS AND PC SUBSTRATES FOR INJECTION MOLDING?

ABS and PC substrates offer excellent mechanical properties, such as impact resistance and high strength-to-weight ratio. They are lightweight, versatile, and exhibit dimensional stability, making them ideal for various applications in industries like automotive and electronics.

2. HOW DOES UV VACUUM METALLIZATION COATING ENHANCE THE APPEARANCE OF ABS AND PC SUBSTRATES?

UV vacuum metallization coating involves depositing a thin layer of metal onto the surface of the substrate, creating a stunning metallic finish. This coating technique simulates the look of chrome, gold, or other desired metal coatings, adding a touch of elegance to the parts.

3. CAN THE UV VACUUM METALLIZATION COATING AFFECT THE MECHANICAL PROPERTIES OF ABS AND PC SUBSTRATES?

No, the UV vacuum metallization coating does not compromise the inherent mechanical properties of ABS and PC substrates. The coating acts as a protective layer, enhancing the part’s durability without sacrificing its impact resistance, toughness, or dimensional stability.

4. WHAT CUSTOMIZATION OPTIONS ARE AVAILABLE WITH UV VACUUM METALLIZATION COATING SERVICES?

UV vacuum metallization coating services offer a wide range of customization options. Manufacturers can achieve different metal finishes, such as chrome or gold, based on their design preferences and target audience’s preferences. This allows for unique and tailored aesthetics to be achieved, ensuring that the final products align with the desired brand image.

5. ARE ABS, PC SUBSTRATES INJECTION PARTS WITH UV VACUUM METALLIZATION COATING SERVICES SUITABLE FOR OUTDOOR APPLICATIONS?

Yes, ABS, PC substrates injection parts with UV vacuum metallization coating services are well-suited for outdoor applications. The coating provides an additional layer of protection, making the parts resistant to UV radiation, moisture, and environmental elements. This ensures that the parts maintain their visual appeal and performance even when exposed to outdoor conditions.

6. HOW DOES THE COST OF ABS, PC SUBSTRATES INJECTION PARTS WITH UV VACUUM METALLIZATION COATING SERVICES COMPARE TO OTHER FINISHING TECHNIQUES?

ABS, PC substrates injection parts with UV vacuum metallization coating services offer a cost-effective solution compared to other finishing techniques. The materials themselves are affordable, and the coating process is efficient and yields consistent results. This makes it an attractive option for manufacturers looking to achieve a premium metallic finish without incurring excessive costs.

plastic injection molded cosmetic packaging with UV Vacuum Metallization Coating.

(Plastic cosmetic packaging parts making and UV vacuum metallization coating service: cnkylt@aliyun.com)

Conclusion

ABS, PC substrates injection parts with UV vacuum metallization coating services provide manufacturers with a winning combination of aesthetics and functionality. The use of ABS and PC substrates ensures excellent mechanical properties, while the application of UV vacuum metallization coating enhances the appearance and durability of the parts. This versatile solution offers a range of customization options, allowing businesses to create distinctive products that stand out in the market. With their cost-effectiveness, streamlined manufacturing process, and eco-friendliness, ABS, PC substrates injection parts with UV vacuum metallization coating services are the go-to choice for industries seeking visually stunning and high-performing components.

KYLT provides a “ONE-STOP SERVICE” of Plastic cosmetic packaging parts injection molding and UV vacuum metallization coating. To get A FREE quotation for your UV-coated ABS, PC, PP material cosmetic package parts price, please Email us: cnkylt@aliyun.com

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology:

评论

发表评论