Lead PB metal alloy die casting machine inject liquid lead alloy to die casting die with high pressure. With this character, this casting machinery also named: high pressure lead injection machine, lead alloy pressure die casting machine, pressure lead injection machine etc.

Lead (Pb) alloy die casting machines are specialized equipment used in the manufacturing process of lead-based products. These machines are typically used in foundries and metalworking facilities to cast molten lead into various shapes and forms.

The Lead (Pb) alloy die casting process involves melting the lead alloy in a furnace and then injecting it into a pre-designed mold under high pressure. The lead alloy cools and solidifies in the mold, taking on the shape and details of the mold cavity. Once the casting has solidified, it is removed from the mold and any excess material is trimmed off.

Lead alloy die casting machines come in various sizes and configurations depending on the specific application and production volume. They are often automated and computer-controlled for precise control over the casting process.

Lead (PB) alloy die casting machines and Lead-acid battery positive spine die casting machines

Lead (PB) alloy die casting machines and lead acid battery positive spine die casting machines are both used in the manufacturing process of lead-based products.

Lead (PB) alloy die casting machines are used to produce various lead alloy products such as pipes, fittings, and sheet metal. These machines use a high-pressure injection process to force molten lead alloy into a die cavity to create the desired shape.

Lead acid battery positive spine die casting machines are specifically designed to manufacture the positive spines used in lead acid batteries. The positive spines are the key component of a battery, responsible for conducting the electrical current from the battery's positive electrode to the outside circuit. These machines use a similar high-pressure injection process to inject molten lead alloy into a die cavity to form the positive spine shape.

While both machines utilize similar manufacturing processes, they are designed for specific products and applications.

Lead PB Die casting machine usage:

Lead PB alloy Die Casting Machine use to produce Pb alloy parts for machinery, fishing tackle, lead acid battery parts, Wheel balance weight etc.

1. Lead alloy parts, Lead acid battery PB alloy parts making machines:

2. Lead alloy fishing sinker, Luya bait making machines:

3. Lead/Pb Alloy Vertical Die Casting Machine for Car/Truck Lead Acid Battery Connector Wire Making:

Lead-acid battery positive spine die casting machines usage

Lead-acid battery positive spine die casting machines use to produce all kinds of battery positive spine or grid etc.

Types of Lead PB die casting machine:

1. Cold chamber Lead PB alloy die casting machine:

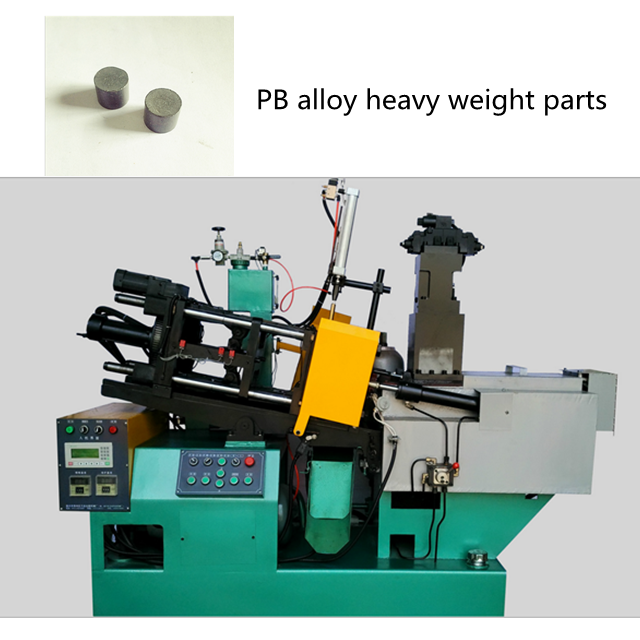

Lead heavy parts for machinery, which as weight parts to keep machine stable. Use cold chamber die casting machine 150T, 200T.

2. Hot chamber Lead PB alloy die casting machines:

Small PB weight part, wheel balance weight use 20T Horizontal lead die casting machine.

Fishing sinker, fishing bait, fishing hook, fishing Luya use 20T Vertical lead die casting machine.

Lead acid battery terminal, bushing, connector etc parts also be cast by our 20T horizontal or vertical machine. Different battery terminal or bushing structure choose different machine type.

KYLT Industrial is your Reliable Lead alloy (PB alloy) Die casting machine manufacturer & supplier & factory. FREE quotation for Lead alloy (PB alloy) die casting machines price, die casting molds, Please Email us: cnkylt@aliyun.com

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论