Magnesium Die Casting Machines: Everything You Need to Know

Are you interested in learning more about magnesium die casting machines? If so, you've come to the right place! In this comprehensive guide, we'll cover everything you need to know about these machines, including Magnesium die casting machines benefits, how Magnesium die casting machines work, and common FAQs.

Description: This guide provides a comprehensive overview of magnesium die casting machines, including their benefits, how they work, and common FAQs. Learn more about these machines here!

Magnesium Die Casting Machines Introduction

Magnesium die casting machines are an essential part of the manufacturing process for a wide range of industries. These machines are used to create complex and detailed components from magnesium, a lightweight and durable material that is commonly used in automotive, aerospace, and consumer electronics applications. In this guide, we'll explore the key features and benefits of magnesium die casting machines, as well as their applications and how they work.

Benefits of Magnesium Die Casting Machines

Magnesium die casting machines offer a range of benefits, including:

High production rates: Magnesium die casting machines can produce large quantities of components quickly and efficiently, making them an ideal choice for high-volume manufacturing.

Lightweight components: Magnesium is a lightweight material, making it an excellent choice for applications where weight is a critical factor, such as in the automotive and aerospace industries.

Complex shapes: Magnesium die casting machines can create components with intricate shapes and details that would be difficult or impossible to achieve with other manufacturing methods.

Cost-effective: Compared to other manufacturing methods, such as machining or forging, magnesium die casting can be a cost-effective option for producing large quantities of components.

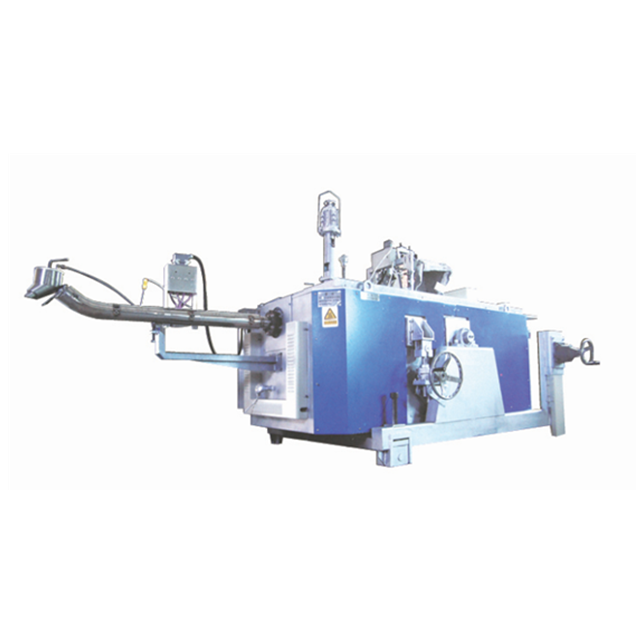

Magnesium Die Casting Machines Types & Tonnages:

Magnesium alloy horizontal cold chamber die casting machines tonnges are about 150t, 280T, 300T, 400T, 500T.

How Magnesium Die Casting Machines Work

Magnesium die casting machines work by injecting molten magnesium into a mold, which is then cooled and solidified to create the desired component. The process typically involves the following steps:

Preparation: The mold is prepared by coating it with a release agent to prevent the magnesium from sticking to the mold.

Melting: The magnesium is melted in a furnace, and any impurities are removed through a process called fluxing.

Injection: The molten magnesium is injected into the mold at high pressure, filling the cavity and creating the desired shape.

Cooling: The mold is cooled, and the component is solidified and removed from the mold.

Finishing: The component is finished by removing any excess material, such as flash or burrs.

REMARK: Magnesium die casting machine must work with magnesium melting furnace. The molten magnesium alloy be quantitative poured into die casting machine cold chamber. Whole melting and pouring process covered by shield gas.

Magnesium Die Casting Machines: Applications and Usage

Magnesium die casting machines are widely used in a range of industries due to the many benefits that magnesium alloys offer, such as high strength-to-weight ratio, excellent thermal conductivity, and high dimensional stability. Let's take a closer look at some of the key applications and usage of magnesium die casting machines.

Automotive Industry

The automotive industry is a major user of magnesium die casting machines, as the lightweight properties of magnesium alloys make them ideal for reducing weight and improving fuel efficiency in cars and trucks. Magnesium components are used in a variety of applications, such as transmission cases, steering wheels, engine blocks, and suspension parts.

Aerospace Industry

The aerospace industry is another significant user of magnesium die casting machines, as magnesium alloys offer a high strength-to-weight ratio and excellent corrosion resistance, making them ideal for use in aircraft and spacecraft components. Magnesium components are used in a variety of applications, such as landing gear components, engine housings, and structural components.

Electronics Industry

The electronics industry is also a major user of magnesium die casting machines, as magnesium alloys offer excellent electromagnetic shielding properties, making them ideal for use in electronic devices. Magnesium components are used in a variety of applications, such as laptop and tablet casings, cell phone frames, and camera bodies.

Medical Industry

The medical industry is another important user of magnesium die casting machines, as magnesium alloys offer biocompatibility and corrosion resistance, making them ideal for use in medical implants and devices. Magnesium components are used in a variety of applications, such as bone screws, spinal implants, and cardiovascular stents.

Other Applications

Magnesium die casting machines are also used in a range of other applications, such as power tools, sporting goods, and household appliances. Magnesium alloys offer excellent durability and corrosion resistance, making them ideal for use in products that require long-term reliability.

Conclusion

Magnesium die casting machines are versatile tools that offer a range of benefits in various industries. By understanding the many applications and uses of magnesium die casting machines, manufacturers can make informed decisions about their manufacturing processes and choose the best solutions for their needs.

KYLT Industrial is your trustable Cold Chamber Die casting machines manufacturer, supplier & factory. More information or Magnesium die casting machines price or technical parameters, please email us: cnkylt@aliyun.com

We will provide more Magnesium die casting machine working process videos, PDF file parameters for your reference.

FAQs

Here are some common questions about magnesium die casting machines:

What materials can be used in magnesium die casting machines?

Magnesium die casting machines are designed specifically for use with magnesium alloys. Other materials, such as aluminum or zinc, require different types of die casting machines.

How long does it take to produce a component using a magnesium die casting machine?

The production time for a component will depend on its complexity and the size of the machine. However, magnesium die casting machines can produce components quickly and efficiently, often in a matter of seconds or minutes.

What are the most common defects in magnesium die casting?

The most common defects in magnesium die casting are porosity, cold flow, shrinkage, and hot tearing. These can be prevented by using proper gating and venting techniques, careful temperature control, and proper design of the die and component.

What are the advantages of magnesium die casting compared to other manufacturing methods?

Magnesium die casting offers several advantages, including the ability to create complex shapes and details, high production rates, and cost-effectiveness compared to other methods such as machining or forging.

What are the environmental considerations of using magnesium die casting machines?

Magnesium is a recyclable material, so components made with magnesium die casting machines can be easily recycled at the end of their life cycle. Additionally, magnesium is a lightweight material that can help reduce fuel consumption in transportation applications.

What safety measures should be taken when operating a magnesium die casting machine?

Safety measures when operating a magnesium die casting machine include wearing protective clothing and equipment, ensuring proper ventilation, and following established protocols for handling and storing magnesium alloys.

Related Metal Casting Machinery:

Die Casting Machines Types:

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Die Casting Machines Classification by Materials:

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Die Casting Machines Application:

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Other

评论

发表评论