Introduction:

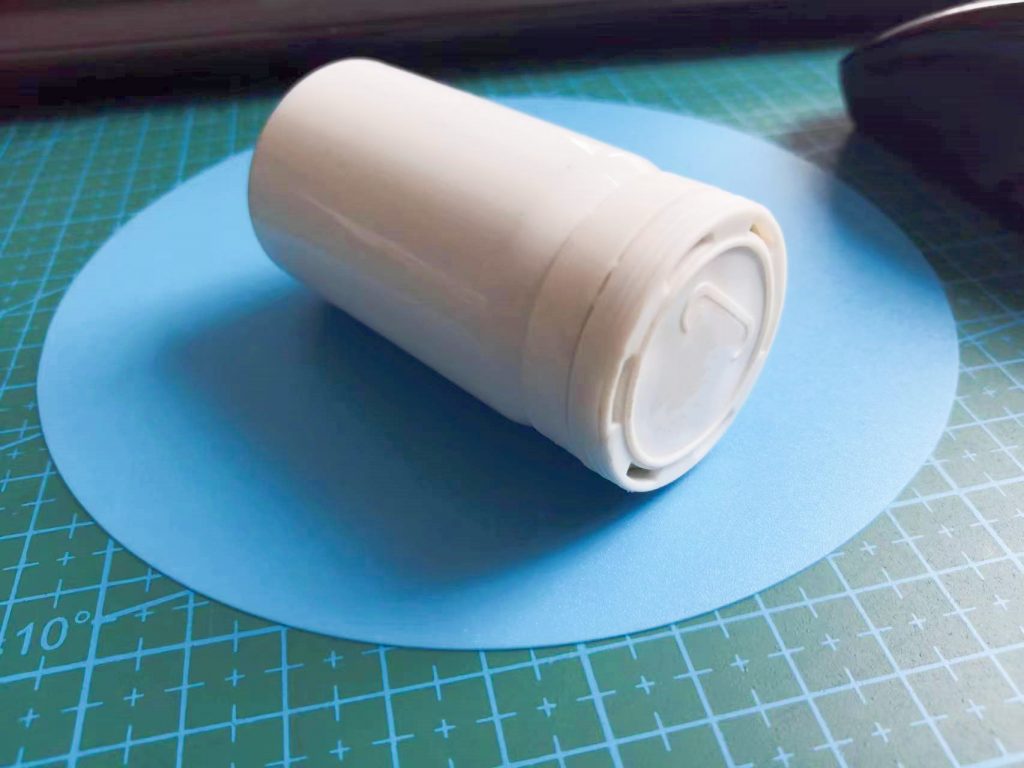

Effervescent tablets are popular pharmaceutical and dietary supplement products that dissolve in water, releasing carbon dioxide gas and creating a fizzy solution. To ensure the stability and efficacy of these tablets, proper packaging is crucial. One effective packaging solution is the effervescent tube with a spiral desiccant closure. This article explores the benefits of this packaging method in preserving the quality and extending the shelf life of effervescent tablets.

KYLT provides Non-standard PE, PP material Spiral Desiccant Closures making services, from mold making to plastic injection molding.

Service email: cnkylt@aliyun.com

The Importance of Packaging for Effervescent Tablets

Effervescent tablets are highly sensitive to moisture, which can impact their composition and potency. Proper packaging is essential to protect these tablets from moisture-related degradation. The effervescent tube provides a secure and airtight container to keep the tablets intact until use. However, to offer enhanced protection against moisture, the addition of a spiral desiccant closure proves to be advantageous.

KYLT provides Non-standard PE, PP material Spiral Desiccant Closures making services, from mold making to plastic injection molding.

Service email: cnkylt@aliyun.com

Understanding the Spiral Desiccant Closure

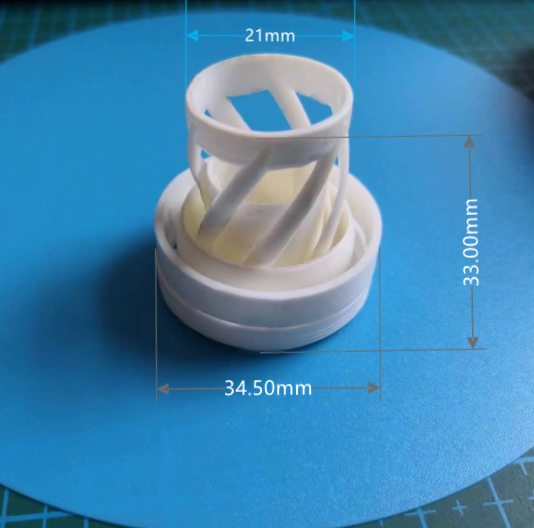

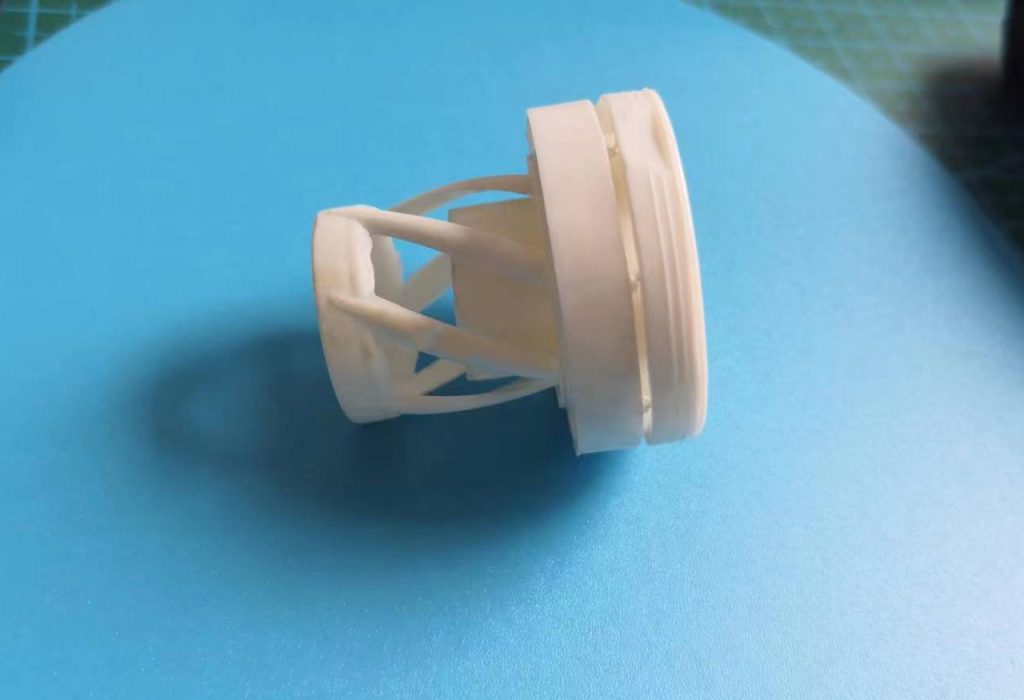

- How Does the Spiral Desiccant Closure Work? The spiral desiccant closure incorporates a separate compartment within the cap that houses a desiccant material. This material, such as silica gel beads or molecular sieves, possesses a high affinity for moisture, effectively absorbing any moisture present inside the tube.

- Maintaining Optimal Moisture Levels By adsorbing moisture from the surrounding environment, the desiccant within the closure helps maintain low humidity levels inside the effervescent tube. This prevents moisture ingress and ensures the tablets remain dry and free from degradation.

Benefits of the Effervescent Tube with Spiral Desiccant Closure

- Enhanced Shelf Life The spiral desiccant closure acts as a barrier against moisture, extending the shelf life of the effervescent tablets. By maintaining a moisture-free environment, the closure helps preserve the tablets’ integrity, potency, and effectiveness over an extended period.

- Protection Against Environmental Factors The desiccant closure not only shields the tablets from moisture but also offers protection against other environmental factors such as humidity and temperature fluctuations. This additional safeguard ensures the tablets remain in optimal condition until they are consumed.

- User-Friendly Design The spiral design of the desiccant closure allows for easy access and dispensing of the effervescent tablets while keeping the desiccant material securely enclosed. This user-friendly design ensures convenience and practicality for consumers.

KYLT provides Non-standard PE, PP material Spiral Desiccant Closures making services, from mold making to plastic injection molding.

Service email: cnkylt@aliyun.com

YOUTUBE VIDEO SHOWS DESICCANT CAP CLOSURE

https://youtube.com/shorts/QZp7FHP1eaU?feature=share

Conclusion:

Effervescent tablets are delicate products that require proper packaging to maintain their quality and efficacy. The effervescent tube with a spiral desiccant closure provides an effective solution by offering enhanced moisture protection and extending the tablets’ shelf life. This packaging design ensures that the tablets remain potent and fizzy, delivering their intended effects when consumed.

KYLT provides FREE quotation for the price of mold and parts of Custom color high quality plastic child-proof bottle cap spiral covers,

Customized color with moisture-proof beads PE PP Plastic spring caps, PP Plastic Injection Desiccant Cap effervescent tablet bottle lid Plastic Caps For Bottles, Childproof spiral cap Child effervescent tablet tube cap CRC cap, Spring caps used for effervescent tablets tube, Cushioning spring caps will silica gel desiccant caps, Healthcare supplement Effervescent tablets tube spring lid and silica gel desiccant stopper, Cap for effervescent tube bottle plastic moisture-proof bottle cap silica gel desiccant closures.

For more information, please email us: cnkylt@aliyun.com

Frequently Asked Questions (FAQs):

Q1: WHY ARE EFFERVESCENT TABLETS SENSITIVE TO MOISTURE?

Effervescent tablets contain active ingredients that can be affected by moisture. Moisture can cause the tablets to break down or deteriorate, reducing their effectiveness. That’s why protecting them from moisture is essential.

Q2: HOW DOES THE SPIRAL DESICCANT CLOSURE PREVENT MOISTURE INGRESS?

The spiral desiccant closure is designed with a compartment that contains a moisture-absorbing material. This material, such as silica gel beads, actively adsorbs moisture, creating a dry environment within the effervescent tube and preventing moisture from reaching the tablets.

Q3: ARE THERE ANY SPECIFIC STORAGE CONDITIONS FOR EFFERVESCENT TUBES WITH SPIRAL DESICCANT CLOSURES?

While the spiral desiccant closure provides effective moisture protection, it’s still recommended to store the effervescent tubes in a cool, dry place away from direct sunlight. Extreme temperatures and high humidity can still have an impact on the tablets’ quality, so it’s best to follow the storage instructions provided by the manufacturer.

Q4: CAN THE DESICCANT MATERIAL BE REUSED OR RECHARGED?

Most desiccant materials used in the spiral desiccant closure are not intended for reuse or recharging. Once they have reached their moisture-absorbing capacity, they need to be replaced with fresh desiccant materials to maintain optimal moisture protection.

Q5: ARE THERE ANY SAFETY CONCERNS WITH THE SPIRAL DESICCANT CLOSURE?

The desiccant materials used in the closure are generally safe and non-toxic. However, it’s important to keep the closure out of reach of children and pets to avoid accidental ingestion. If any concerns arise, it’s recommended to consult the manufacturer or seek professional advice.

Q6: CAN THE EFFERVESCENT TABLETS BE CONSUMED IF THE DESICCANT MATERIAL LEAKS INTO THE TUBE?

If the desiccant material accidentally leaks into the effervescent tube, it’s best to avoid consuming the tablets. While the desiccant material is generally safe, it is not meant for ingestion. Discard any tablets that have come into contact with the desiccant and consult the manufacturer for further guidance.

Q7: CAN THE EFFERVESCENT TUBE WITH SPIRAL DESICCANT CLOSURE BE RECYCLED?

Effervescent tubes with spiral desiccant closures are often made of recyclable plastics. However, it’s essential to check the local recycling guidelines to ensure proper disposal. Separating the closure from the tube and recycling them accordingly can help reduce environmental impact.

KYLT CNC Machining Services:

Home>CNC Machining Services>CNC Milling Services

Home>CNC Machining Services>CNC Turning Services

Home>CNC Machining Services>Rapid Prototyping Services

Home>CNC Machining Services>Injection Molding Services

KYLT CNC Precision Machined Parts:

Home>Precision CNC Machined Parts

Home>Precision CNC Machined Parts>CNC Precise Turned Parts

Home>Precision CNC Machined Parts>CNC Precise Milled Parts

Home>Precision CNC Machined Parts>Aluminum Machining

Home>Precision CNC Machined Parts>Magnesium Machining

Home>Precision CNC Machined Parts>Copper & Brass Machining

Home>Precision CNC Machined Parts>Steel Machining

Home>Precision CNC Machined Parts>Stainless Steel Machining

Home>Precision CNC Machined Parts>Plastic Machining

More information about Machining Technology:

评论

发表评论