Where to buy a complete set of parts to assemble disposable skin staplers? What are the specific parts in the complete set? How to assemble these parts?

If you are a medical device purchaser or manufacturer, you would like to purchase a complete set of standard disposable skin suture accessories that are commonly used in the market at the most favorable price, without the need to invest in molds and have your brand.

Please contact us: cnkylt@aliyun.com

"Ensure medical quality, source manufacturer supplies complete sets of molds and accessories for disposable skin sutures, providing a stable and reliable accessory option for your medical devices."

We are the ORIGINAL Full Set of Disposable Skin Stapler Spare Parts Manufacturer & Supplier!

Three key questions of disposable skin staplers manufacturing:

Firstly, we need to address three issues regarding the procurement and production of disposable skin stapler parts: where to buy a complete set of parts? What are the specific parts in the complete set? How to assemble these parts?

1. Who can supply the full set of components of a disposable skin stapler?

We are the source factory of metal parts and injection molded parts for disposable skin sutures, with over 15 years of experience in providing molds and injection molding production for medical device manufacturers. We provide free samples for customers to assemble and test, and request samples: cnkylt@aliyun.com

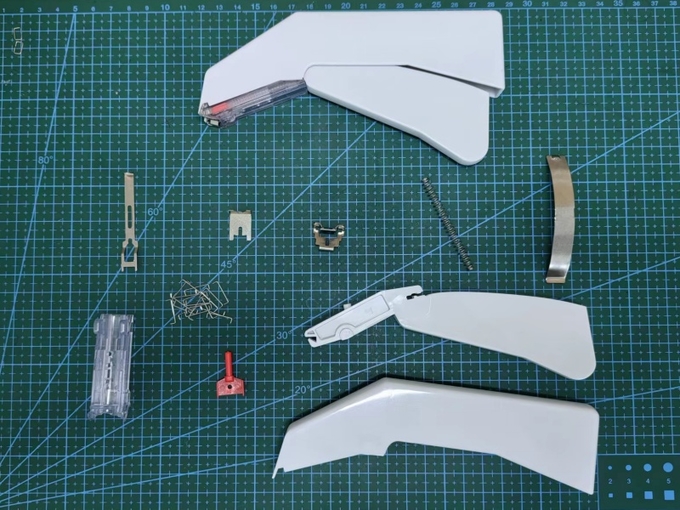

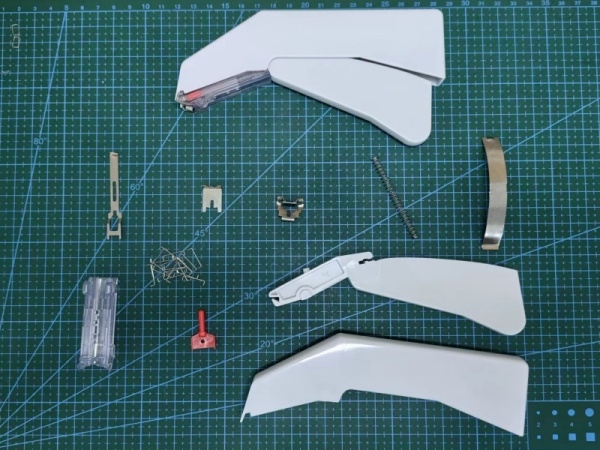

2. What parts does the disposable surgical skin stapler contain?

The complete set of disposable shell skin staplers consists of ten parts: Plastic Shell - 1pcs; Plastic Firing handle - 1pcs; Plastic staples pushing plate - 1pcs; Plastic suture staple base - 1pcs; Spring - 1pcs; Spring plate - 1pcs; Suture nail base - 1pcs; Staples (nail) -35pcs. Of course, if you need skin staples remover, also please me know.

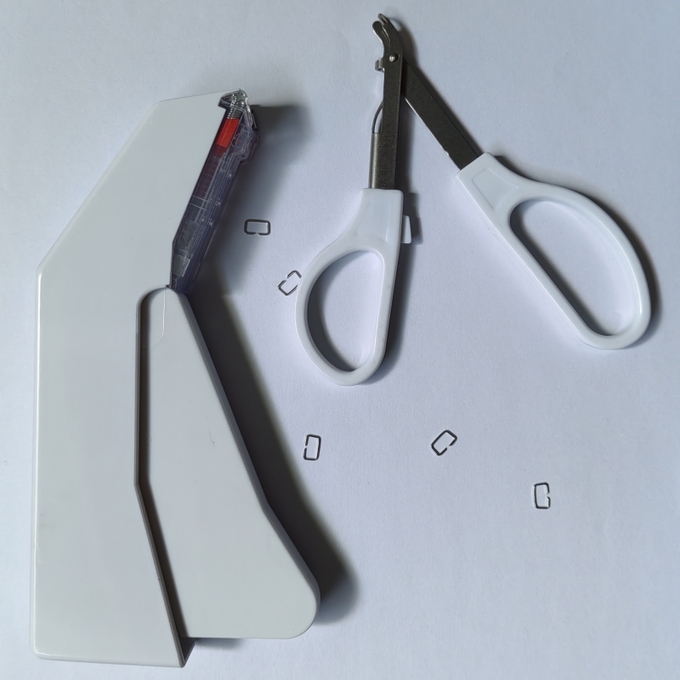

3. How to assemble the accessories of a disposable skin stapler, is there a video of the assembly process?

Introduction to Disposable Skin Stapler Spare Parts

Importance of Using Genuine Spare Parts

Using genuine spare parts is crucial for maintaining the effectiveness and safety of disposable skin staplers. Genuine parts are designed to meet the specific requirements and quality standards of the original equipment manufacturer (OEM), ensuring compatibility and optimal performance.

This disposable surgical skin stapler comes with 35 staples. We will randomly select each component for assembly and check if the quality of each component is stable, in order to ensure that the quality of the accessories received by customers is excellent.

Components of Disposable Skin Stapler

Disposable skin staplers consist of several key components, each playing a vital role in the stapling process. Our disposable skin stapler consists of 10 pieces of spare parts, detailed as follows:

1. SHELL

2. STAPLES PRESSING PLATE

3. STAPLES BOX, SUTURE NAIL BOX

4. FIRING HANDLE

5.SPRING

6. STAPLES PUSHING PLATE

7. STAPLES

8. STAPLES FORMING PART

9. SPRING PLATE

10 STAPLES (SUTURE NAIL) BASE

Material and Function of Every Spare Part In Skin Stapler

Maintenance of Disposable Skin Stapler & Eery Spare Parts

This surgical skin stapler is disposable and does not require daily maintenance.

Benefits of Using Genuine Spare Parts

Risks of Using Non-Genuine Spare Parts

Tips for Choosing the Right Spare Parts

Where to Source Genuine Disposable Skin Stapler Spare Parts?

As the source factory of medical device accessories, we have 15 years of experience in medical product mold making and injection molding. We provide year-round accessory production and product development services to various medical device manufacturers. All parts of this skin stapler are factory sourced accessories, and are the same type of accessory for various medical device manufacturers.

We can provide free samples and offer the best factory prices. Please contact us for sample requests: cnkylt@aliyun.com

FAQs

Q1. What is a skin stapler used for?

A1. A skin stapler is used for closing wounds during surgery or in emergency medical situations.

Q2. Why do they use staples instead of stitches?

A2. Staples are often used instead of stitches for their speed and ease of application, particularly in areas with high tension or where precise alignment is difficult.

Q3. Are skin staplers reusable?

A3. Skin staplers can be disposable or reusable, depending on the type and manufacturer.

Q4. Does stapling a wound work?

A4. Stapling a wound can be effective for closing it quickly and securely, but it's important to ensure proper technique and follow-up care to prevent complications.

评论

发表评论