In machining process, tapping method normally used to making screw thread for machined workpiece. So, as a machining operator, who should got more knowledge about screw thread making.

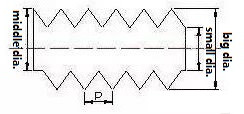

Screw thread Shape (standard metric thread)

1.From the picture, we can see that:

P indicates that the pitch is the distance from the tooth to the cusp or the base of the tooth.

Usually the expression is M3 x 0.5, which is pitch in mm.

(M stands for Metric system) and 3 stands for nominal size. The so-called size is the maximum diameter of the screw teeth or the maximum diameter of the internal thread.

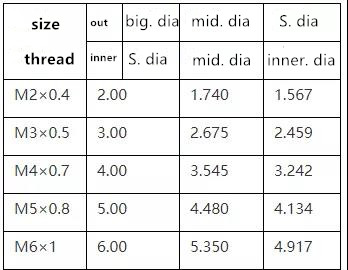

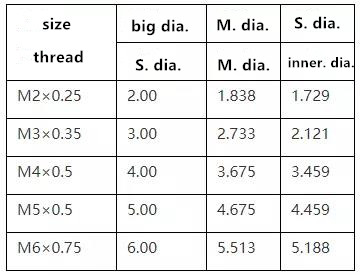

2.General standard screw teeth, large diameter (or root diameter) must conform to the nominal size of the screw teeth, while the diameter (internal thread is the same) and small diameter (internal thread is called internal diameter) must conform to the figures found in the specifications as follows (metric standard rough thread).

If it is a fine thread, the clearance will become smaller, and its large, medium and small diameter will change accordingly.

3.British thread are the same, but the pitch is expressed by the number of teeth in an inch, such as: 1/4-20UNC, that is, the outer thread 1/4 “big diameter (6.35mm) has 20 teeth per inch.

- UNC (UNFIED THREAD)

- C superficial coarse teeth

- F superficial fine teeth

- EF superfine teeth

- C, F and EF have different pitches

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论