CNC milling machine or CNC router are used to making precision machined parts, such metal workpiece and plastic parts especially in rapid prototype making. The key element is to choose suitable cutting tool, install cutter good and change cutter as per CNC machining requirement.

How to select, install and change cutter in CNC machining center?

The tool magazine is very important to the machining center. All kinds of working procedures are finished by the tool magazine.

GENERALLY, THERE ARE THREE TYPES OF TOOL MAGAZINE:

Disc type, hat type and chain type.

The selection of tool change and tool magazine in small machining center can determine the number of tools needed according to the process analysis results of the workpiece to be processed.

Generally, the capacity of tool magazine is determined by the number of tools needed for one part in one clamping, because when changing another part for machining, it is necessary to re arrange the tools in small machining center, otherwise the tool management is complex and prone to errors.

Small five axis machining center is a very popular machine tool at present. It is mainly used in maker studios and scientific research institutions in Colleges and universities to process small parts and teaching in Colleges and universities. Its biggest characteristics are high cost performance, good stability, strong reliability and high processing accuracy. Small machining centers can process some parts of plane, curved surface and variable angle. The biggest disadvantage of small five machining centers is that they have certain constraints on the scale of machining parts.

From the statistical data point of view, it is suitable for small machining centers to select about 20 tool magazine and horizontal machining centers to select about 40 tool magazine. Of course, it should be determined according to the actual needs. For the machining center machine tool of flexible manufacturing cell (FMC) or flexible manufacturing system (FMS), the tool magazine capacity should be large capacity, or even equipped with exchangeable tool magazine.

The procedure of tool installation, tool change and tool selection for small machining center:

It is very simple to install a tool in a small machining center. Record the type and use of the tool and the corresponding tool holder number. Select any tool holder in the tool magazine to install the tool.

DURING TOOL CHANGE, THERE ARE THREE SITUATIONS AS FOLLOWS:

- The tool on the spindle of machining center is optional tool holder, and the tool to be replaced is fixed tool holder

Steps: tool magazine → tool selection → to tool change position → manipulator takes out the tool → install the spindle, and send the tool removed from the spindle to the empty tool position nearby.

- The tool on the spindle of the small machining center is placed in the fixed tool holder, while the tool to be changed is optional or fixed

Tool change steps: tool magazine → tool selection → to tool change position → take out the tool by manipulator → install the spindle. When the tool removed from the spindle is put into the tool magazine, the tool magazine shall be turned to the position where the tool is received in advance.

- The tool on the spindle and the tool to be replaced are optional tool holders

The tool change procedure is as above, and the tool removed by the spindle is loaded into the tool holder of the tool to be changed.

There are three ways to select cutter in small machining center:

- Select the tools in sequence, install the tools in the tool holder according to the use sequence of the tools, select them one by one according to the sequence, and put them back to the original position after use.

- Select the cutter at will, code the cutter holder, put the corresponding cutter into the designated cutter holder, and mark the cutter holder code with the address T when programming.

- Memory of tool selection: in the memory of machining center, record the tool number, tool storage position and tool holder number. When the storage address of the tool changes, the memory of machining center will also change. The tool library of small machining center is equipped with a position detection device, so that the tool can be taken out and returned at will.

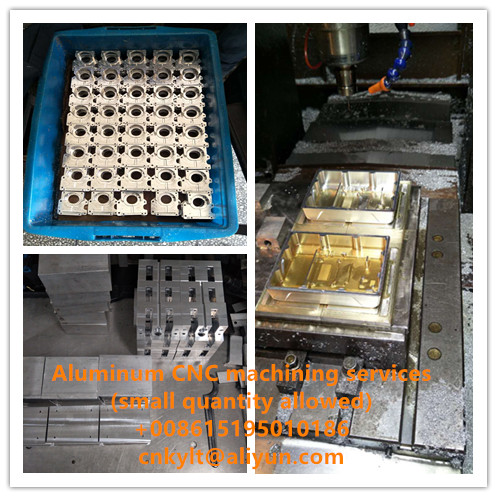

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论