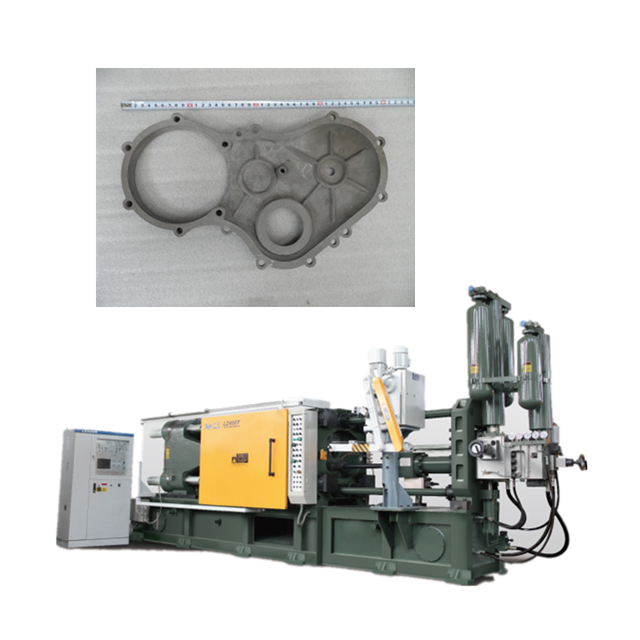

Automotive Parts Die Casting Machine used to make aluminum engine shell, housing, cover, pully, bracket, steering wheel, steering stents, padle, electric box, light heatsink, lamp housing, bus reflector bracket etc. Email: cnkylt@aliyun.com

Automotive Parts Die Casting Machine mainly used to manufacture aluminum alloy parts for cars, buses,turck and electric vehichles. The aluminum products applications from enginer spare parts to electric system.

Brake wires with zinc terminal also is an important in automotive manufacturing process.

Vertical hot chamber die casting machine with mold used to cast zinc shaped structure with wire ropes. L type vertical machine is traditional version with semi-auto operation. T type vertical machine have more spaces in front and back sides, can be connect with auto wires feeding machine and pick-up machine, cutting machine to reach full automatic working.

Why Aluminum alloy is popular used in automotive industry?

Die Casting Machines can be used to produce complex structure spare parts with good quality. That is the reason: why die cast automotive parts are widely used in automotive manufacturing process. With the development of electric cars, more and more aluminum die casting parts be used. For example, Tesla special ordered Heavy-duty cold chamber die casting machines to cast aluminum electric car body.

Which materials can be used to produce automotive parts by die casting machine?

Die casting process is very popular for producing metal automotive parts, the materials involves: Aluminum, Zinc, Magnesium, Copper alloys. Die casting is a metal processing method, which use pressure to force molten metal into a die casting mold. Auto Cars consist of many die cast parts, especially aluminum die cast parts. Many examples of die casting automotive parts available in original cars manufacturing and automobile spare parts market today. Here we will find out how die cast metal parts are used in automotive.

Usage examples of Die Casting Automotive Parts.

Automotive parts manufactured by casting methods can be classified: high pressure die casting, low pressure/gravity die casting etc.

1.Gravity casting/low pressure parts like: Aluminium Alloy Automobile Wheels, Motorcycle Fork Shock Absorber, Automobile engine cylinder head etc.

2.High pressure die casting adopts hot chamber die casting machine and cold chamber die casting machine. Which used to produce zinc and aluminum automotive parts.

With high pressure cold chamber die casting machine, that can produce big size zinc and aluminum auto parts. Such as: automobile steering wheel, Automobile engine chain cover, Automobile starting motor parts etc.

150T, 200T, 300T Horizontal Cold Chamber Die Casting Machines suitable to produce small Aluminum auto parts weight from 10g to 3Kg.

350T, 400T, 500T,550T, 700T Aluminum die casting machine to produce middle scale Auto parts.

800T,1100T,1300T Cold chamber machine for big size auto parts.

Aluminum Die Casting Automotive Parts Usage:

1. Car body: Now electric car/vehicle are developing quickly. Tesla car bodies are made from aluminum by die casting.

2. Engine Parts: Engine assembly mounting system, cylinder heads and engine covers etc are die cast aluminum parts.

3. Brackets: Such as Automobile engine support parts.

4. Electronic Box,Shell and Covers: Such as gearbox, motor, shades pole and motor covers are made from aluminum alloy by die casting.

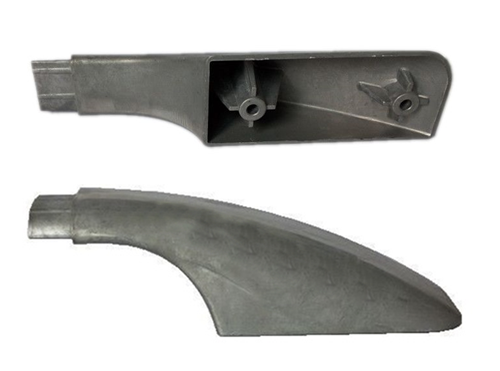

5. Other auto parts such as car door handle, auto fork, components etc automotive parts are made by die casting.

For high pressure hot chamber die casting machine, which used to produce small zinc/zamak alloy auto parts. Such as car door handle, Car Cigarette Lighter etc small parts.

Zinc/Zamak Die Casting Automotive Parts Usage:

Vertical hot chamber die casting machine for brake wires zinc end making are popular service for many famous auto car brands. Such as SHIMANO use our special ordered brake wire zinc end die casting machine to produce auto brake cables.

Vertical hot chamber die casting machine for brake wire zinc end making types: 12T,20T.

One shot can produce 6-8pcs wires, one min. has 5 shots. Wire position stopper or retainer be used to limit the wire position and not move in injection process. Our T version vertical machine has enough space for set auto wire feeding machine and cast wire pick-up and cutting robot. With those automatic machine, the wire casting process can reach automatic production.

Photos shows our T type vertical brake wire zinc termainl die casting machine in SHIMANO factory. Which has been connect with a cooling unit.

Which materials can be used to produce automotive parts by die casting machine?

Die casting process is very popular for producing metal automotive parts, the materials involves: Aluminum, Zinc, Magnesium, Copper alloys. Die casting is a metal processing method, which use pressure to force molten metal into a die casting mold. Auto Cars consist of many die cast parts, especially aluminum die cast parts. Many examples of die casting automotive parts available in original cars manufacturing and automobile spare parts market today. Here we will find out how die cast metal parts are used in automotive.

Why Aluminum alloy widely used in automotive parts?

Die Casting Machines can be used to produce complex structure spare parts with good quality. That is the reason: why die cast automotive parts are widely used in automotive manufacturing process. With the development of electric cars, more and more aluminum die casting parts be used. For example, Tesla special ordered Heavy-duty cold chamber die casting machines to cast aluminum electric car body.

Automotive parts require strong mechanical character, light weight, low cost. Although magnesium alloy is strong and lighter than aluminum, its material cost is higher, magnesium casting machines and machining processes are more expensive and complex. That decided aluminum die casting process can not be instead now.

Aluminum is lightweight and strong, aluminum die casting parts are used for automotive, car or automobile production applications. In order to get better fuel economy of cars, the use of Aluminum Auto Parts help to reduce the weight of the automobile. Aluminum alloy material cost is relatively affordable and stable. Auto manufactures prefer aluminum die casting for their auto parts, because several thousand parts can be produced a year at a very low cost. Some original Equipment Manufacturers(OEM), Auto manufactures own die casting plants to produce auto parts. Others are cooperate with die casting factories to produce aluminum auto parts.

Service for the automobile, aftermarket auto parts are same made from aliminum die casting. Those auto parts are sold in mall and stores. Aftermarket auto parts manufacturers use die cast aluminum auto parts because the manufacturing cost is cheap and have better quality.

(For automobile refitting market, aluminum rapid Prototype parts, Customized Parts are made by CNC machining, bending, welding etc process.)

More information about our Automotive parts Die Casting Machine and Mould Service, Please email us: cnkylt@aliyun.com.

评论

发表评论