20T Vertical die casting machine used to Zinc end brake wire/cable, Lead fishing sinker (Luya), bolt terminal of lead acid battery, battery terminal clamp connector pile head etc. More information, please email: cnkylt@aliyun.com

20T Vertical die casting machine (hot chamber) consists of machine body, mold clamping mechanism, injection system, cooling system, melting furance, electric system etc. It adopts hydraulic drive, electric operation, and has manual and automatic operation. Melting furance is heated by electrical heated tube, so its operation is easy, and it has big adjustment range and wide application scope. The brand of hydraulic valve, time relay, general relay, AC contactor, microswitch of this machine is domestic and oversea famous, so it is running stable and performing excellence. It runs efficiently after adjustment. This machine is suitable for zinc alloy, lead alloy and tin alloy casting of hardware, electrical appliance, tool industry etc.

What are the vertical hot chamber die casting machines used for?

Vertical hot chamber die casting machine normally used to produce zinc or lead alloy parts with have insert parts which must be cast together. Such as brake wires of car and bike, fishing sinker, lead metal fishing lure, lead Luya bait, lead acid battery terminal with bolt,battery wire connector etc.

20T Brake wire/cable making vertical die casting machine

To cast zinc terminal with wirerope. The manufacturing process need: die casting machine, die casting die, wireropes. Operator manual set wireropes on mold cavities. Normally 12T machine one time set 6 wireropes, 20T can set 8 wireropes.

The machine can be used to cast bike wire cable, motorcycle brake wire, car brake cable or wirerope with zinc end terminal.

20T zinc end wire casting machine L-type machine Youtube video:

Lead alloy metal fishing sinker, lead metal fishing lure, lead Luya bait making

As ring, hook and other metal piece need be cast together with lead alloy to produce fishing parts. Vertical lead alloy injection machines are used, with the horizontal operating platform, worker can set metal insert to mold cavties easily and conveniently. The manufacturing of small lead (Pb.) alloy fishing parts use 12T vertical type, for big Luya bait need use 20T vertical type.

20T vertical die casting machine for fishing sinker/fishing lure/lead Luya bait making Youtube video:

Lead acid battery terminal with bolt, copper nut manufacturing

Vertical die casting machine can set bolts, nut, copper insert in mold cavites easily. In lead acid battery terminal making process, those metal insert parts can be set in good positions.

For 20T lead acid battery bolt terminal vertical die casting making machine video, please email us: cnkylt@aliyun.com

20T Vertical hot chamber die casting machine specification:

20T high pressure vertical hot chamber die casting machine parameters:

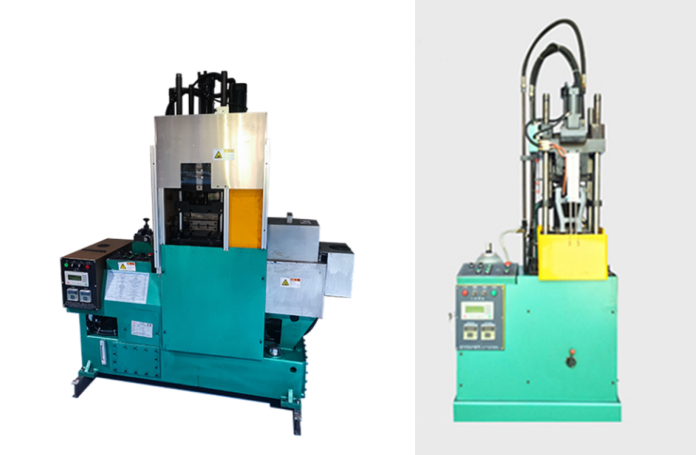

20T Vertical die casting machine types:

L type, T type.

1. 20T L-type vertical die casting machine

This vertical machine melting furance pot is at right angle with clamping mechanism and control panel. The whole machine structure view like letter "L". That is the reason we call it as L type machine.

Vertical L type machine is standard structure. We have two kinds tonnages: 12T, 20T.

2. 20T T-type high pressure hot chamber vertical die casting machine

Vertical T type hot chamber die casting machine developed on the standard horizontal hot chamber die casting machine. T type machine body and melting furance are same the with horizontal machine. Machine clamping mechanism is at right angle with machine body. The whole machine structure like inverted letter "T", that is the reason we call this machine is T type.

Our 200kn T type vertical hot chamber die casting machine is speical ordered by a world famous brake wire manufacturer. They need auto robots in front and back side of the machine. T type machine has more space to set wire cutting robot in machine front. Back side has enough space to set pick-up and stamping robots. Metal alloy be melted in the machine right side furance by electric tubes. Nozzle injects molten alloy from bottom of fixed mold platen to mold cavities at right angle.

20T S-type vertical die casting machine for brake wire zinc end making Youtube video:

https://www.youtube.com/watch?v=cBZXtBaEbAk

As per client demand, we provide machine and mold improve service. This 20T S-type machine be designed special stop mechanism for wires position locking - Wire retainer.

Youtube video of wire retainer working process and wires setting:

About 20T Vertical hot chamber die casting machine price, or die casting mould, please feel free to email us: cnkylt@aliyun.com We will choose suitable machine types, suggestions of mould design, provide free die casting samples.

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论