LZ4000KN High Pressure PLC Die Cast Machine factory. Over 35 years experience of the die casting machine design and manufacturing.

400 Ton PLC Horizontal High Pressure Die Cast Machine Specification (LZ400T)

(Remark: 1.The die casting machine supplier keeps the right to revise above parameters, If there is any alterations, advance notice won't be given then. 2. Servo die casting machine can be choosed to save energy and cost. )

Full automatic aluminum cold chamber die casting video:

Youtube: https://youtu.be/npYbgva3NK8

Manual die casting video:

Youtube: https://youtu.be/LCafa6yLESc

Die casting working process of cold chamber horizontal machine:

Die casting machine operator ladles the liquid Aluminum/Zinc/Copper alloy out from furnace, pure it into pressure casting chamber. Cold chamber die casting machine plunger inject the liquid metal alloy to pressure die with high pressure. Metal alloy solid, die open, the die casting parts be ejected out from mould cavities. A die casting injection process is finished, sprayer lubricates and cools the die cavites, mould close, and ready to start the next pressure die casting cycle.

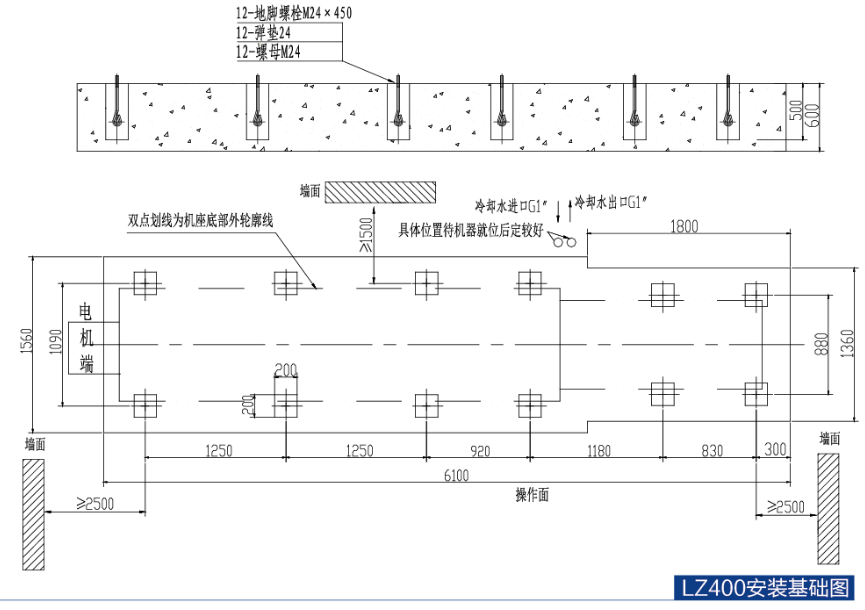

LZ 400 Ton PLC Horizontal High Pressure Die Cast Machine Cement Ground Specification:

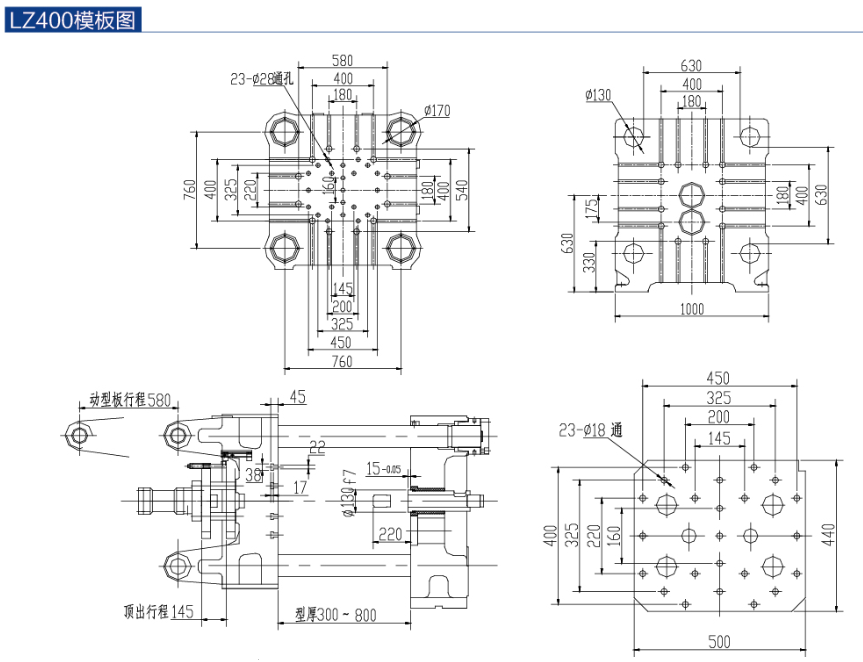

LZ 400 Ton PLC Horizontal High Pressure Die Cast Machine Molding Plate Specification:

Servo driven die casting machine

Servo driven system is an advisable choice for die casting machine factory. It features:

Energy saving

Rapid response and improved efficiency

Stable pressure and precision

High repetition accuracy

High speed and large lifting flow

Connection mode to improve heat dissipation performance

Cold Chamber Die Casting Machine Auxiliary Machines:

Auxiliary machines used to save labor or reach automatic die cast process.

Aluminum melting furnace

Automatic ladling machine

Spraying Machine

Auto part off machine (Die casting parts pick-up machine / Extractor)

Automatic aluminum die casting production line working video:

https://www.youtube.com/shorts/npYbgva3NK8

Technical information and prices of 400Ton PLC Horizontal High Pressure Die Cast Machine, Automatic ladling machine, Auto Spraying machine, Auto die cast parts pick-up machine and melting furnace, Please email: cnkylt@aliyun.com

Related Casting Machinery:

Die Casting Machine

· Battery Spine Die Casting Machine

· Cold Chamber Die Casting Machine

· Hot Chamber Die Casting Machine

· Vertical Die Casting Machine

Material

· Aluminum Die Casting Machine

· Magnesium Die Casting Machine

Application

· Auto Parts Die Casting Machines

· Kitchen &Household Parts Die Casting Machines

· Lamps Light Parts Die Casting Machines

· Electric Vehicle Spare Parts Die Casting Machines

· Hardware, Jewelry, Clothing Accessories Die Casting Machines

· Tel-Communication Equipment Parts Die Casting Machines

· Garden Machinery & Electric Tools Parts Die Casting Machines

· Lead Acid Battery Terminal Bushing, Battery Positive Spine Grid Die Casting Machines

· Fishing Sinker Die Casting Machines

· Others

评论

发表评论