The commonly used tooling and fixture are mainly divided into the following categories according to their functionality:

- clamping mould

- drilling and milling tooling

- numerical control and instrument clamping head

- gas and water testing tooling

- trimming and punching tooling

- welding tooling

- polishing fixture

- assembly tooling

- pad printing, laser lettering tooling

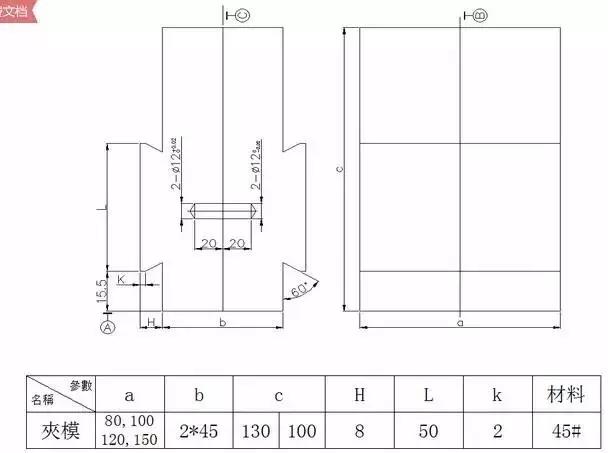

Clamping mould

Definition: tools for positioning and clamping with product shape

Key design points:

- This kind of clamping die is mainly used on vice, and its length can be cut as required;

- Other auxiliary positioning devices can be designed on the clamping die, which is generally connected by welding;

- The figure above is a diagram, and the die cavity structure size is determined by the specific situation;

- Fit the locating pin with diameter 12 tightly at the appropriate position on the moving die, and slide the locating hole at the corresponding position of the fixed die to fit the locating pin;

- During the design of the assembly cavity, it is necessary to offset and enlarge 0.1mm on the basis of the shape surface of the blank drawing file without shrinkage.

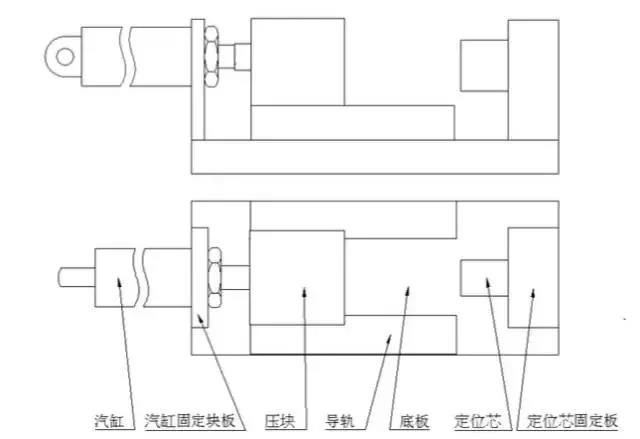

Drilling and milling tooling

Key design points:

- If necessary, some auxiliary positioning devices can be designed on the fixed core and its fixed plate;

- The figure above is the structure diagram, which needs to be designed according to the product structure.

- The cylinder is determined according to the size of the product and the stress during processing. Sda50x50 is commonly used.

KYLT provide all kinds of drilling & milling tooling for the work-piece & prototypes manufacturing.

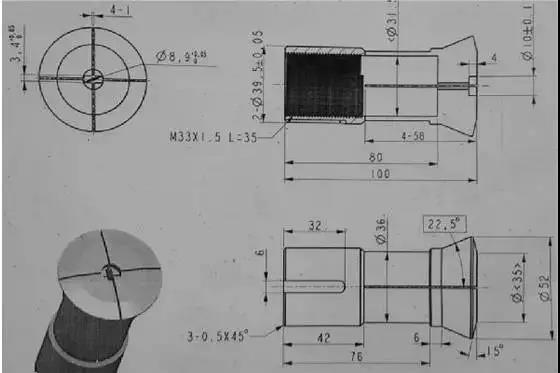

Numerical control and instrument clamping tool

- CNC chuck

- Inner chuck

Key design points:

- The unmarked size in the figure above is determined according to the inner hole size structure of the actual product;

- The outer circle in contact with the positioning of the inner hole of the product shall be left with a margin of 0.5mm on one side during manufacturing, and finally installed on the CNC machine tool to finish turning to the size, so as to prevent the deformation and eccentricity caused by the quenching process;

- It is recommended to use spring steel for the assembly part, and 45 × for the pull rod part.

- The thread M20 of the pull rod part is a common thread, which can be adjusted according to the actual situation.

INSTRUMENT INNER CHUCK

Key design points:

- The figure above is a reference diagram, and the assembly size and structure are determined according to the actual product’s overall dimension structure;

- The material is 45 × and quenched.

INSTRUMENT OUTER CHUCK

Key design points:

- The figure above is for reference, and the actual size is determined according to the inner hole size structure of the product;

- The outer circle in contact with the positioning of the inner hole of the product shall be left with a margin of 0.5mm on one side during manufacturing, and finally installed on the instrument lathe to finish turning to the size, so as to prevent the deformation and eccentricity caused by the quenching process;

- The material is 45 × and quenched.

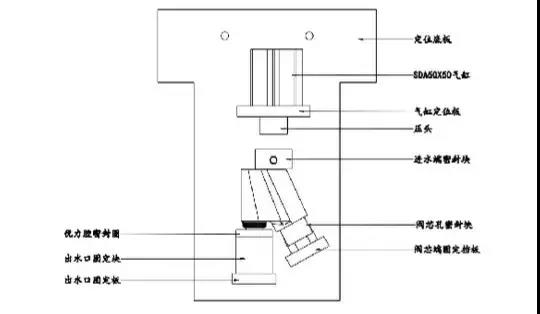

Gas testing tooling

Key design points:

- The figure above is the reference drawing of gas testing tooling. The specific structure shall be designed according to the actual structure of the product. The idea is to seal the product in as simple a way as possible, and make the part to be tested and sealed filled with gas to confirm its tightness;

- The size of the cylinder can be adjusted according to the actual size of the product. At the same time, it is necessary to consider whether the stroke of the cylinder can meet the convenience of taking and placing the product.

- The sealing surface in contact with the product is generally made of the materials with good compression capacity, such as the high strength adhesive and NBR rubber ring. At the same time, it should be noted that if there is a positioning block in contact with the product appearance surface, the white rubber plastic block should be used as far as possible and the cotton cloth should be covered during the use to prevent the product appearance from being damaged.

- During the design, the orientation of the product shall be considered to prevent the occurrence of false inspection due to the gas inside the product cavity.

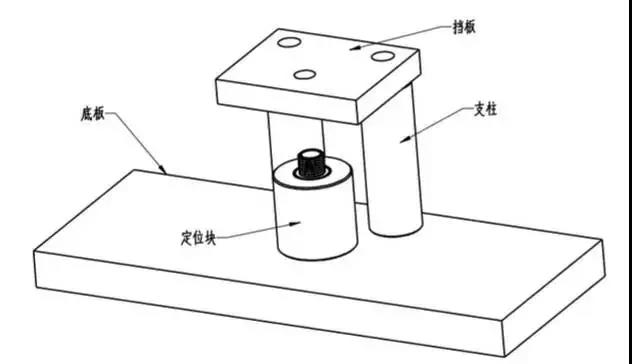

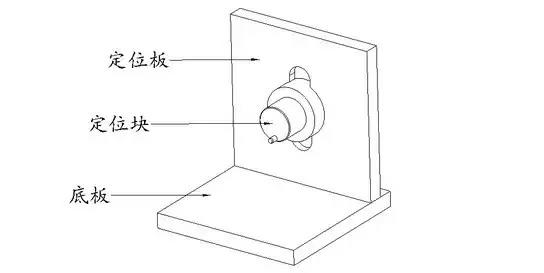

Punching tooling

Key design points: the figure above shows the common structure of punching tooling. The function of the bottom plate is to facilitate the fixation on the working table of the press; the function of the positioning block is to fix the product, and the specific structure is designed according to the actual situation of the product, and the center point is around to facilitate the safe taking and placing of the product; the baffle plate is used to facilitate the separation of the product from the punching knife; the pillar is used to fix the baffle plate. The assembly position and size of the above parts can be designed according to the actual situation of the product.

Welding tooling

The welding tooling is mainly used to fix the position of each component in the welding assembly and control the relative size of each component in the welding assembly. Its structure is mainly the positioning block, which needs to be designed according to the actual structure of the product. It should be noted that sealing space shall not be generated between the tools when the product is placed on the welding tooling, so as to prevent the excessive pressure of sealing space in the process of welding heating from affecting the size of parts after welding.

Polishing fixture

Assembly tooling

Assembly tooling is mainly used in the assembly process of the assembly of auxiliary positioning device. The design idea is that the product can be conveniently taken and placed according to the structure of component assembly, the appearance surface of the product can not be damaged during the assembly process, and the cotton cloth can be covered to protect the product during the use process. Try to use non-metallic materials such as white glue on the selection of materials.

Pad printing, laser lettering tooling

Key points of design: design the positioning structure of the tooling according to the lettering requirements of the actual situation of the product, pay attention to the convenience of taking and placing the product, and the protection of the product appearance, and try to use non-metallic materials such as white glue for the positioning block and the auxiliary positioning device in contact with the product.

KYLT Precision CNC machining services (milling & turning service), Fast prototyping, Fixture/Jig/Tooling making, Aluminum die casting & plastic injection parts. Email:cnkylt@aliyun.com +008615195010186

KYLT CNC Machining Services:

KYLT CNC Precision Machined Parts:

More information about Machining Technology:

评论

发表评论